High-resolution printing device and printing equipment

A printing device and high-resolution technology, applied in the field of print heads, can solve the problems of difficulty in improving resolution, high cost, and high price of print heads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

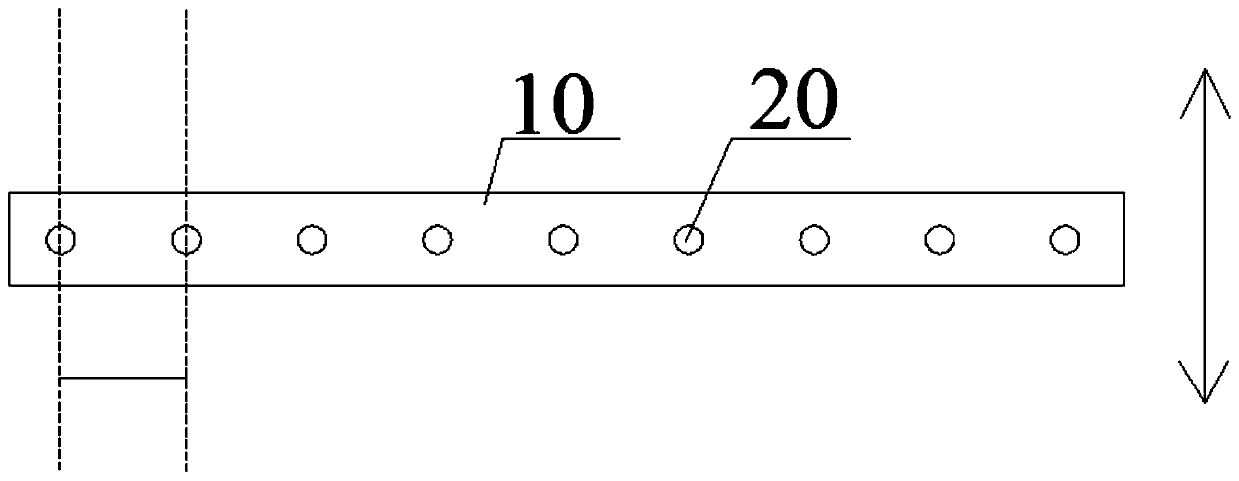

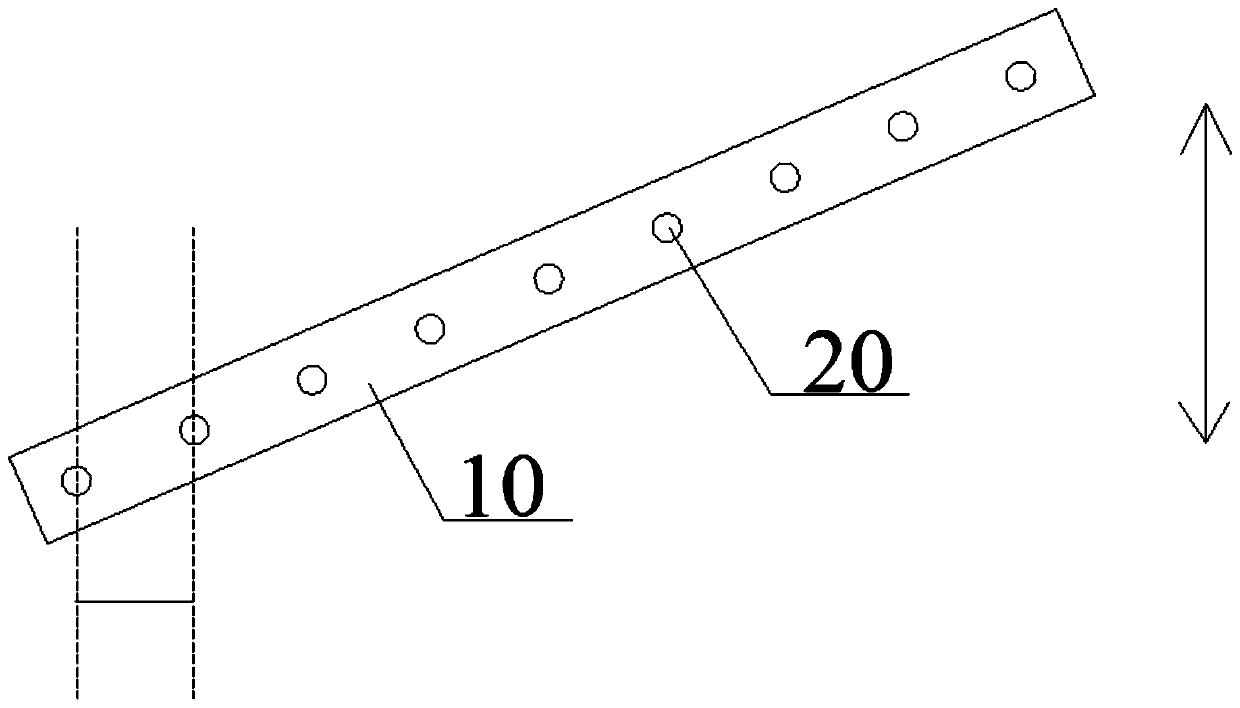

[0064] Refer to attached figure 2 As shown, a high-resolution printing device performs inkjet work along the printing direction, including a nozzle 10 and an installation base 30, and at least one row of uniform nozzle holes 20 is arranged on the nozzle 10, and the nozzle 10 is arranged on the On the above-mentioned installation base 30, the angle between the straight line where the row of nozzle holes 20 is located and the straight line where the printing direction is located in the same horizontal plane is not equal to 90°, and the straight line where the row of nozzle holes 20 is located and the direction where the printing direction is located in the same horizontal plane are not equal to 90°. The angle formed by the straight line is not equal to 0°.

[0065] It can be seen that using this scheme, using and attaching figure 1 The spray head 10 of the same resolution, but inclined to reduce the distance between the nozzle holes 20 and the nozzle holes 20, thereby achievin...

Embodiment 2

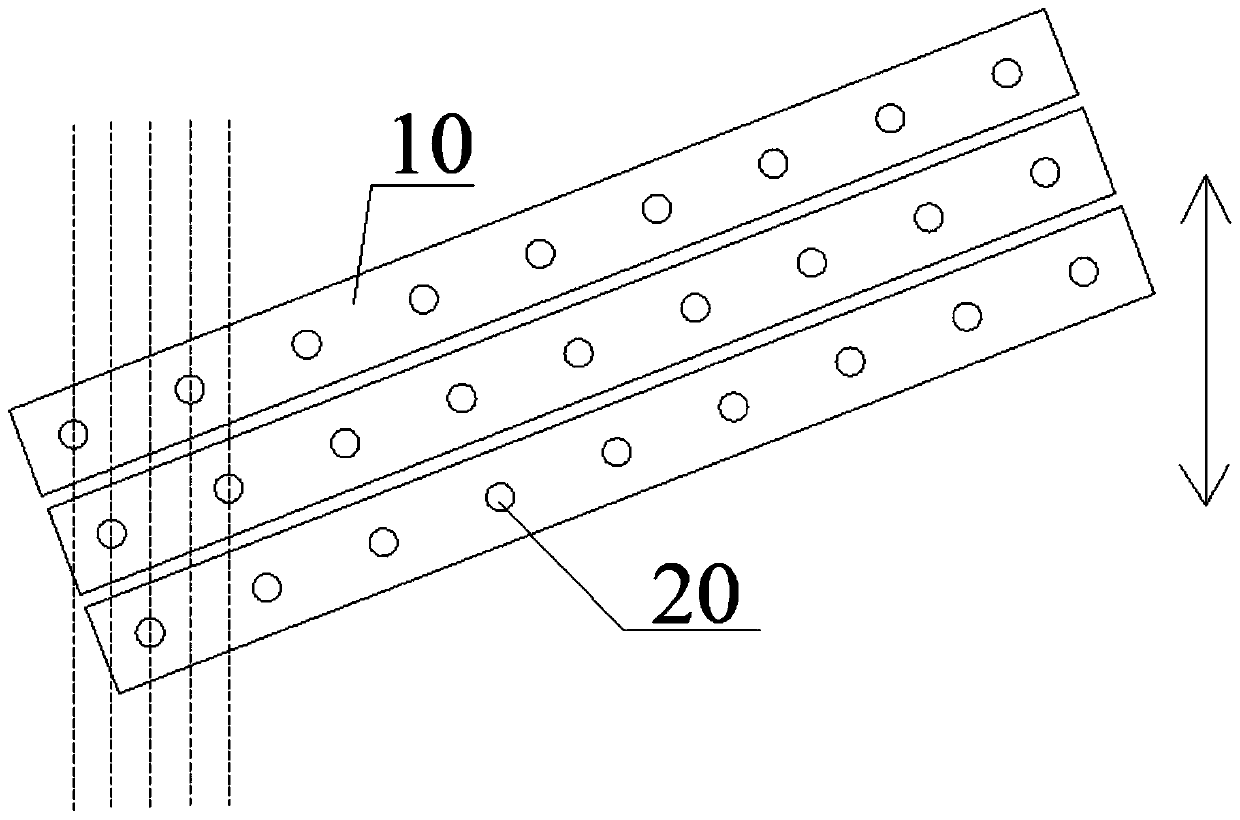

[0067] Refer to attached image 3 As shown, a high-resolution printing device performs inkjet work along the printing direction, including a nozzle 10 and an installation base 30, the nozzle 10 is arranged on the installation base 30, and the nozzle 10 is arranged in two or two rows Above the nozzle holes 20, the straight line where one row of nozzle holes 20 is located is parallel to the straight line where another row of nozzle holes 20 is located, and all the nozzle holes 20 are in an array, wherein the straight line where the horizontal row of nozzle holes 20 is located is perpendicular to the straight line where the column row of nozzle holes 20 is located. The included angle formed by the straight line where the row of nozzle holes 20 is located and the straight line where the printing direction is located in the same horizontal plane is not equal to 90°, and the included angle formed by the straight line where the row of nozzle holes 20 is located and the straight line w...

Embodiment 3

[0071] Refer to attached Figure 4As shown, a high-resolution printing device performs inkjet work along the printing direction, including a nozzle 10 and an installation base 30, the nozzle 10 is arranged on the installation base 30, and the nozzle 10 is arranged in two or two rows Above the nozzle holes 20, the straight line where one row of nozzle holes 20 is located is parallel to the straight line where the other row of nozzle holes 20 is located, and all the nozzle holes 20 are in an array, wherein the straight line where the horizontal row of nozzle holes 20 is located and the straight line where the column row of nozzle holes 20 are located are formed The included angle is not equal to 90°. The included angle formed by the straight line where the row of nozzle holes 20 is located and the straight line where the printing direction is located in the same horizontal plane is not equal to 90°, and the included angle formed by the straight line where the row of nozzle holes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com