Light-emitting diode module and production method thereof

A technology of light-emitting diodes and manufacturing methods, applied to semiconductor devices of light-emitting elements, light sources, optical elements for changing the spectral characteristics of emitted light, etc., which can solve the problems of increased production costs, unsuitable assembly of light-emitting diodes, limited design flexibility, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

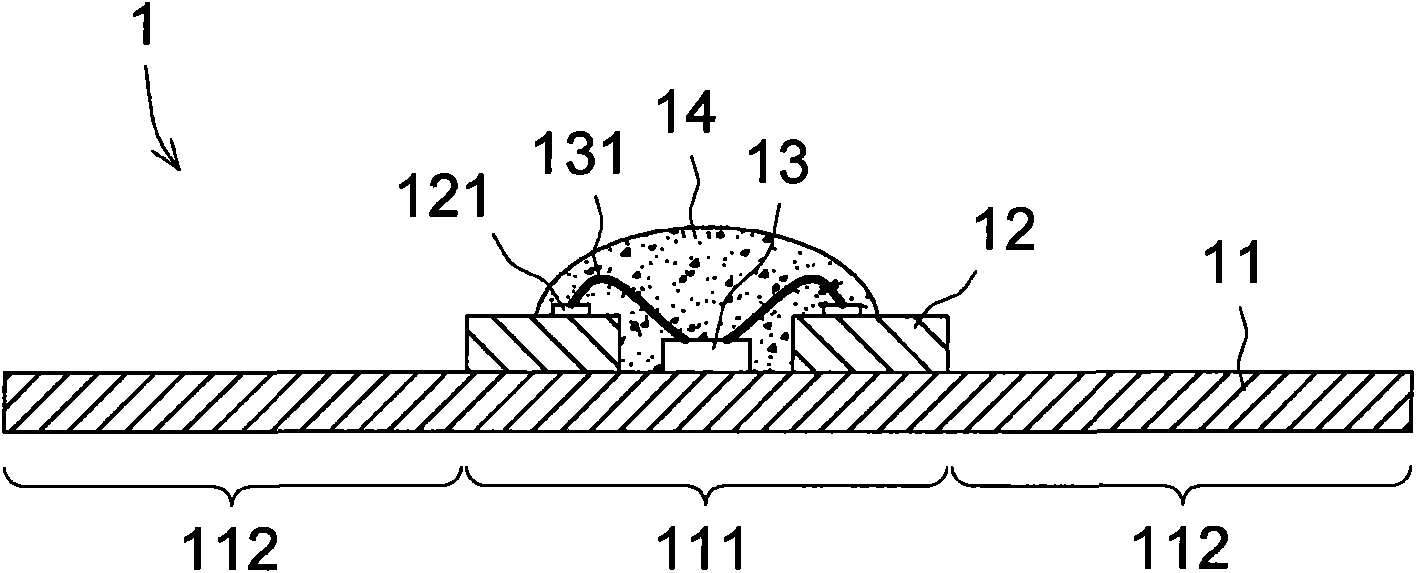

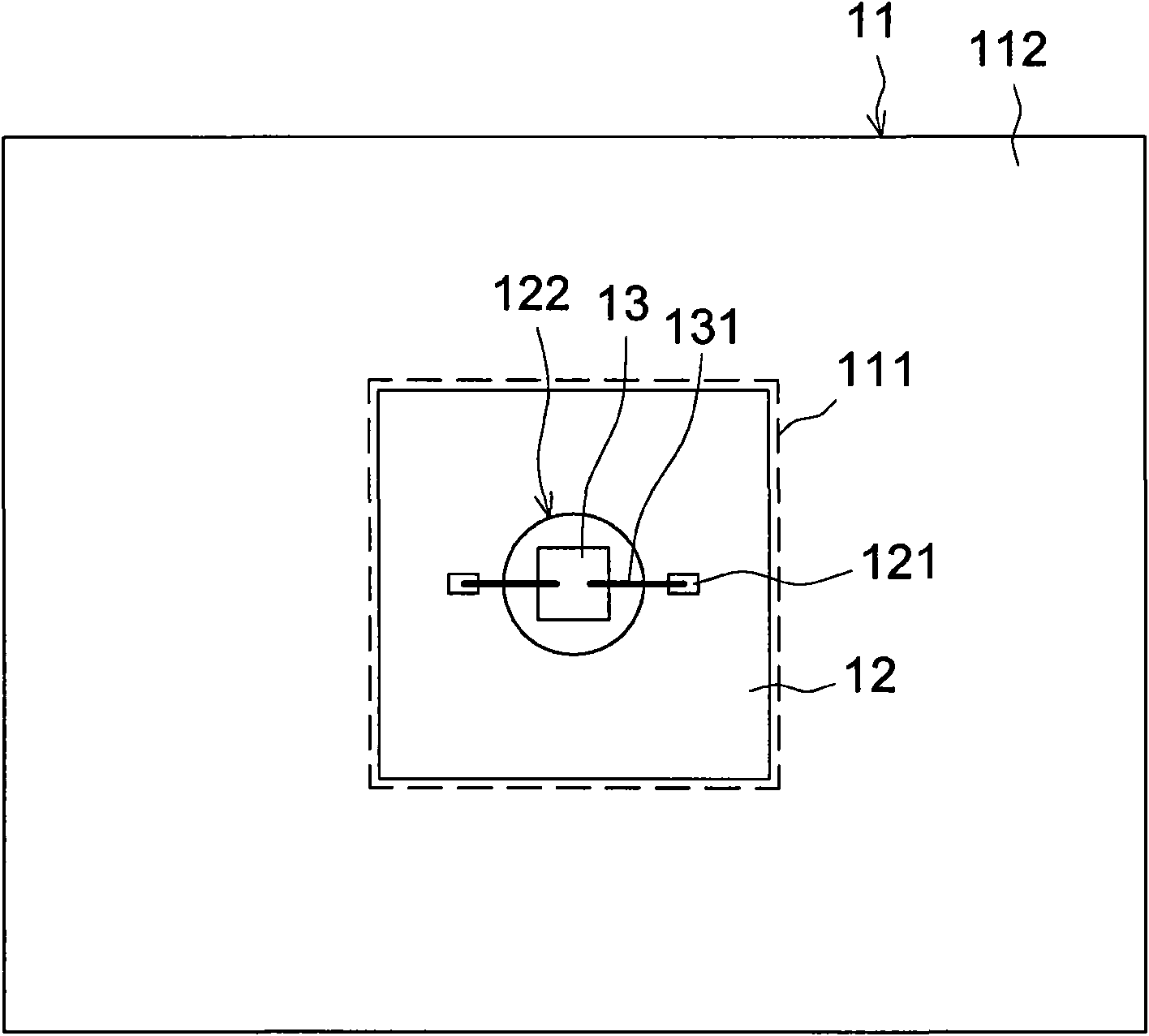

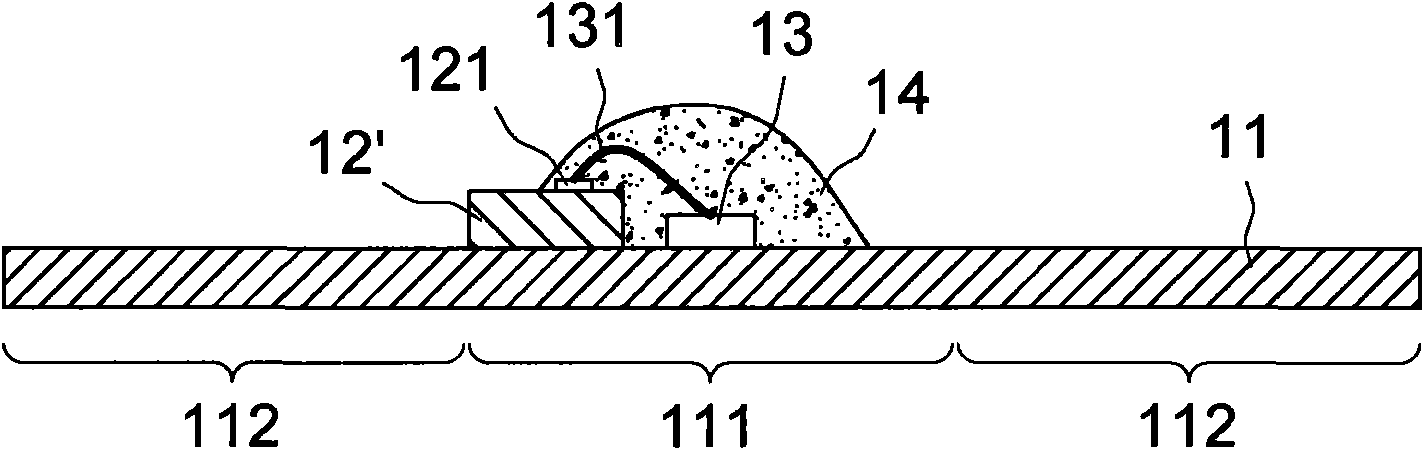

[0039] Please refer to Figure 1a as well as Figure 1b , illustrating the LED module 1 of the present invention, wherein Figure 1a is a cross-sectional side view of the LED module 1 of the present invention, Figure 1b It is a top view of the LED module 1 of the present invention with the light-transmissive packaging component 14 removed. The LED module 1 of the preferred embodiment of the present invention includes a carrier board 11 , at least one substrate 12 , at least one LED 13 and at least one light-transmitting packaging component 14 . The carrier board 11 has a loading area 111 and a forming area 112 , wherein the forming area 112 can be arbitrarily processed into a specific shape according to design requirements. The substrate 12 is disposed on the carrying area 111 of the carrier 11 . The substrate 12 has at least one circuit layer, for example, the circuit layer includes conductive contacts 121 . In an embodiment, the substrate 12 can be a copper foil substrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com