Cable turntable

A turntable and cable technology, applied in the field of submarine cable untwisting device, can solve the problems of submarine cable untwisting and other problems, and achieve the effect of solving installation difficulties, stable transmission ratio, and good equipment safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below with reference to the accompanying drawings and embodiments.

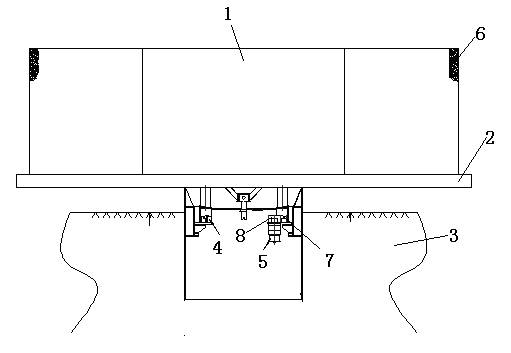

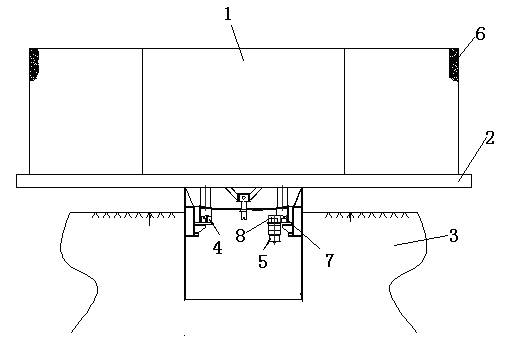

[0012] like figure 1 As shown, the cable turntable of the present invention includes a hydraulic turntable 2, a cable bridge, a bearing plane bearing 4, a transmission internal gear 7, a driving gear 8, a hydraulic motor 5, and the like.

[0013] The hydraulic turntable 2 is installed on the construction vessel and may rotate in forward and reverse directions. The inlet and outlet of the cable bridge can be adjusted left, right, up and down. The base of the hydraulic turntable 2 and the installation deck 3 of the construction ship are movably connected by the bearing plane bearing 4. The transmission internal gear 7 is fixedly installed under the base of the hydraulic turntable 2, which is connected with the transmission The drive gear 8 meshed with the internal gear 7 is fixed on the output shaft of the hydraulic motor 5 whose speed, torque and power ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com