Special resin for solar film and preparation method thereof

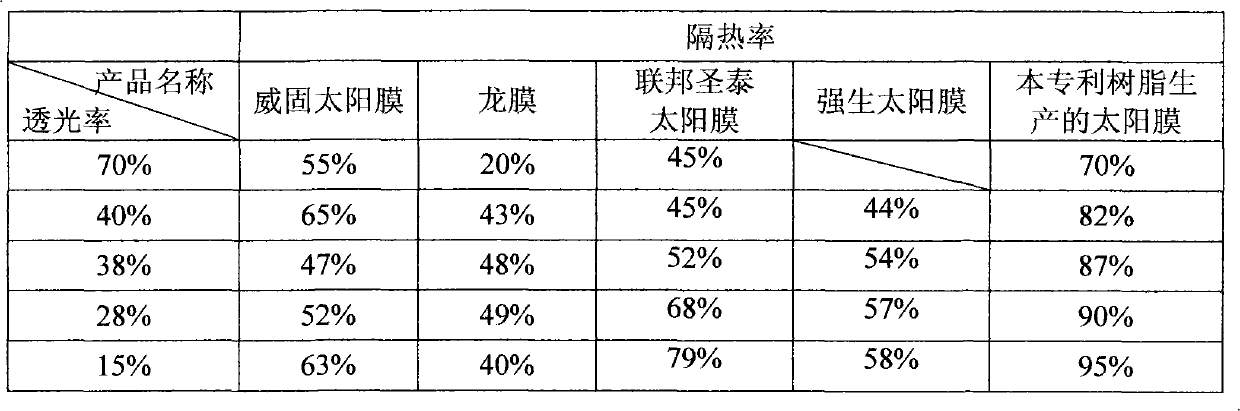

A technology of solar film and resin, applied in the field of resin for solar film, can solve the problems of poor heat insulation effect, complicated production process of solar film and high cost, and achieve the improvement of heat insulation effect, good film-forming performance, and improvement of unique properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0026] Specific embodiment one: a kind of special resin of new solar film, its raw material composition is by weight: 3 parts of polyvinyl alcohol, 1.5 parts of n-butyraldehyde, 0.15 part of ethanol, 0.06 part of pigment, 0.3 part of reagent grade hydrochloric acid, alkaline auxiliary 0.3 parts of agent, 0.1 part of dispersant, 0.015 parts of ultraviolet blocking agent, 0.015 parts of infrared blocking agent, 0.03 parts of antioxidant, 30 parts of pure water.

[0027] The steps of its specific preparation method are:

[0028] (1) dissolve

[0029] Add 30 parts of pure water into the reactor, start the agitator, slowly put 3 parts of polyvinyl alcohol into the reactor, start heating to 95-99°C, and keep it warm for 4-6 hours to ensure that the polyvinyl alcohol is completely dissolved;

[0030] (2) Reaction

[0031] Lower the temperature of the solution to room temperature (20-25°C), add 1.5 parts of butyraldehyde to the polyvinyl alcohol solution, and stir for 5 minutes; the...

specific Embodiment 2

[0036] Concrete embodiment two: a kind of novel solar film special resin, its raw material composition is by weight: 4 parts of polyvinyl alcohol, 2 parts of n-butyraldehyde, 0.2 part of ethanol, 0.07 part of pigment, 0.4 part of reagent grade hydrochloric acid, alkaline auxiliary 0.4 part of agent, 0.1 part of dispersant, 0.02 part of ultraviolet blocking agent, 0.02 part of infrared blocking agent, 0.04 part of antioxidant, 40 parts of pure water.

[0037] The steps of its specific preparation method are:

[0038] (1) dissolve

[0039] Add 40 parts of pure water to the reactor, start the agitator, slowly put 4 parts of polyvinyl alcohol into the reactor, start heating to 95-99°C, and keep it warm for 4-6 hours to ensure that the polyvinyl alcohol is completely dissolved;

[0040] (2) Reaction

[0041] Lower the solution temperature to normal temperature (20-25°C), add 2 parts of butyraldehyde to the polyvinyl alcohol solution, stir for 5 minutes; Slowly and evenly add ant...

specific Embodiment 3

[0046] Specific embodiment three: a kind of special resin of new solar film, its raw material composition is by weight: 5 parts of polyvinyl alcohol, 2.5 parts of n-butyraldehyde, 0.25 part of ethanol, 0.08 part of pigment, 0.5 part of reagent grade hydrochloric acid, alkaline auxiliary 0.5 parts of agent, 0.3 parts of dispersant, 0.025 parts of ultraviolet blocking agent, 0.025 parts of infrared blocking agent, 0.05 parts of antioxidant, 50 parts of pure water.

[0047] The steps of its specific preparation method are:

[0048] (1) dissolve

[0049] Add 50 parts of pure water into the reactor, start the agitator, slowly put 3 parts of polyvinyl alcohol into the reactor, start heating to 95-99°C, and keep it warm for 4-6 hours to ensure that the polyvinyl alcohol is completely dissolved;

[0050] (2) Reaction

[0051] Lower the solution temperature to normal temperature (20-25°C), add 2.5 parts of butyraldehyde to the polyvinyl alcohol solution, stir for 5 minutes; Slowly a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com