Oil and gas well underground straddle packing layer-by-layer fracture acidizing tool tubular column structure

A technology of fracturing acidification and downhole spanning, which is applied in the directions of sealing/isolation, wellbore/well components, drill pipes, etc., and can solve problems such as limited number of layers, complicated completion string and post-workover, and unsatisfactory results , to achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

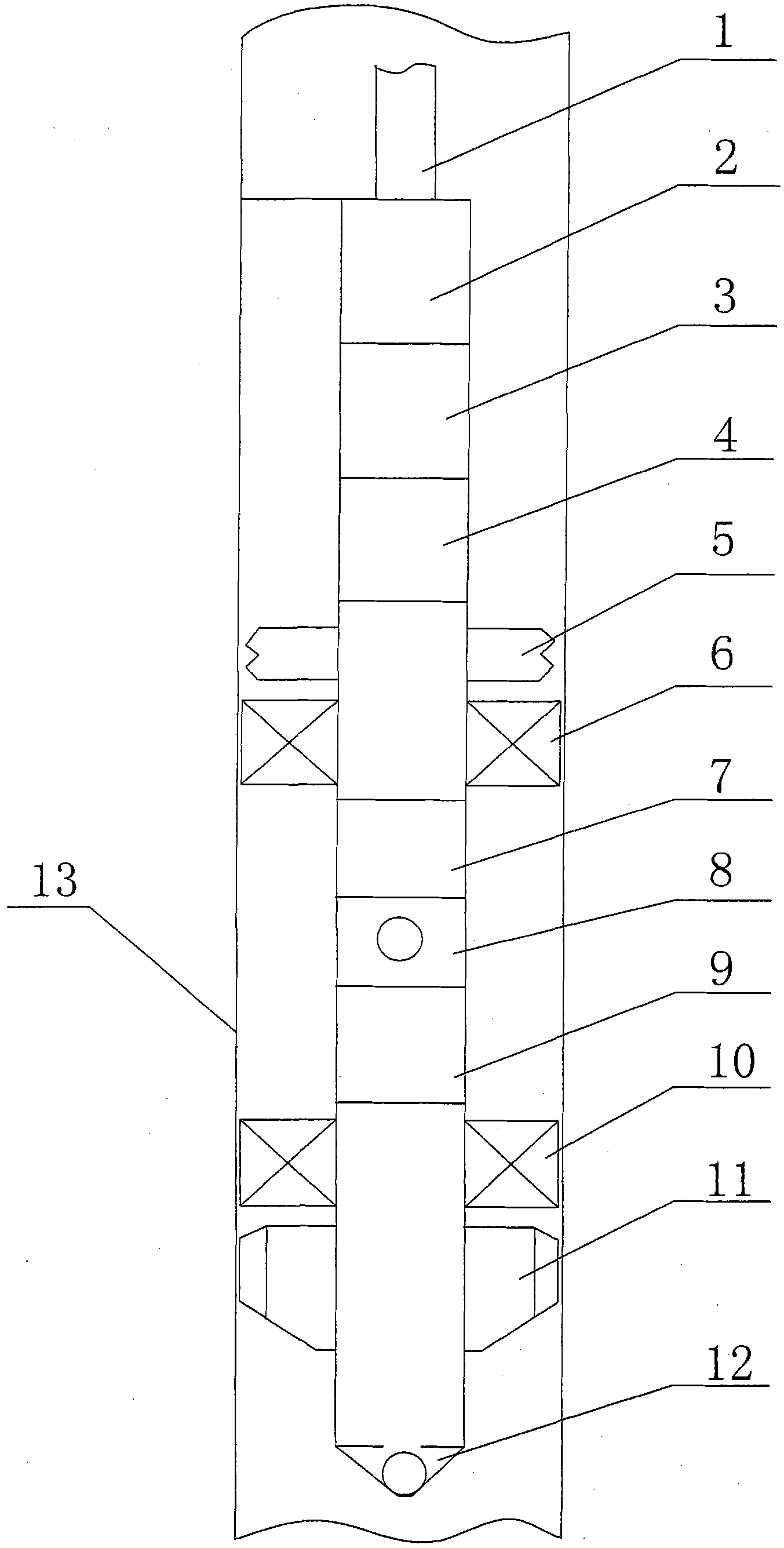

[0014] Structure and connection relationship of the present invention: the present invention includes a packing device and a connecting device, the packing device is composed of an upper packer 6 and a lower packer 10, and the connecting device is composed of a safety release device 2, a circulation valve 3, and a positioner 4. Supporting formal hydraulic anchor 5, upper adjustment short circuit 7, sand blasting acid sprayer 8, lower adjustment short circuit 9, centralizer 11, upper packer 6 connected to vertical hydraulic anchor 5 and upper adjustment short circuit 7 Between them, the lower packer 10 is connected between the lower adjustment short-circuit 9 and the centralizer 11, and the present invention is connected in the following order from top to bottom: safety release device 2, circulation valve 3, positioner 4, and support type hydraulic anchor 5. Upper packer 6, upper adjustment short connection 7, sand blasting acid sprayer 8, lower adjustment short connection 9, lo...

Embodiment 2

[0016] Main purpose of the present invention: in the construction process, the device of the present invention has the following important functions: the safety release device 2 is arranged on the uppermost end of the string, the upper end of the safety release device 2 is connected to the coiled tubing 1, and the safety release device 2 It is controlled by shear pins and claws. After each construction is completed, when the pipe string needs to be pulled out, if the downhole pipe string is stuck by sand settling, in order to pull out the unstuck pipe string in time, it can be thrown from the safety The hand device 2 is separated, and all the coiled tubing 1 on the upper part is pulled out, which can reduce losses; the circulation valve 3 is set at the lower end of the safety device 2, and can be opened by counter-pressing or throwing a ball to suppress the pressure. During the construction process, if the When the backwashing sand process is not available for sand plugging, th...

Embodiment 3

[0018] Process of the present invention: the present invention is composed of the following components: the uppermost end is a coiled tubing 1, and the following are connected in turn with a safety release device 2, a circulation valve 3, a positioner 4, a support type hydraulic anchor 5, an upper packer 6, an upper Adjusting short connection 7, sandblasting and acid blasting device 8, lower adjusting short connection 9, lower packer 10, centralizer 11, the lowermost end of the pipe string is connected to the check valve 12; the above components are connected by threads, and the above components are composed The pipe string is lowered to a certain depth in the downhole casing 13 of the oil and gas well with a coiled tubing operation vehicle, and positioned by the positioner 4 so that the upper and lower packers 6 and 10 are positioned at the upper end of the perforated interval below At the same time, the side holes of the sandblasting and acid spraying device 8 are also aligne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com