High precision positioning column reinforcement positioning hoop

A positioning hoop, high-precision technology, applied in the direction of structural elements, building components, building reinforcements, etc., can solve the problems of easy deviation of column reinforcement, affecting project quality, time-consuming and labor-intensive problems, so as to avoid manual correction and improve work efficiency , The effect of convenient installation and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

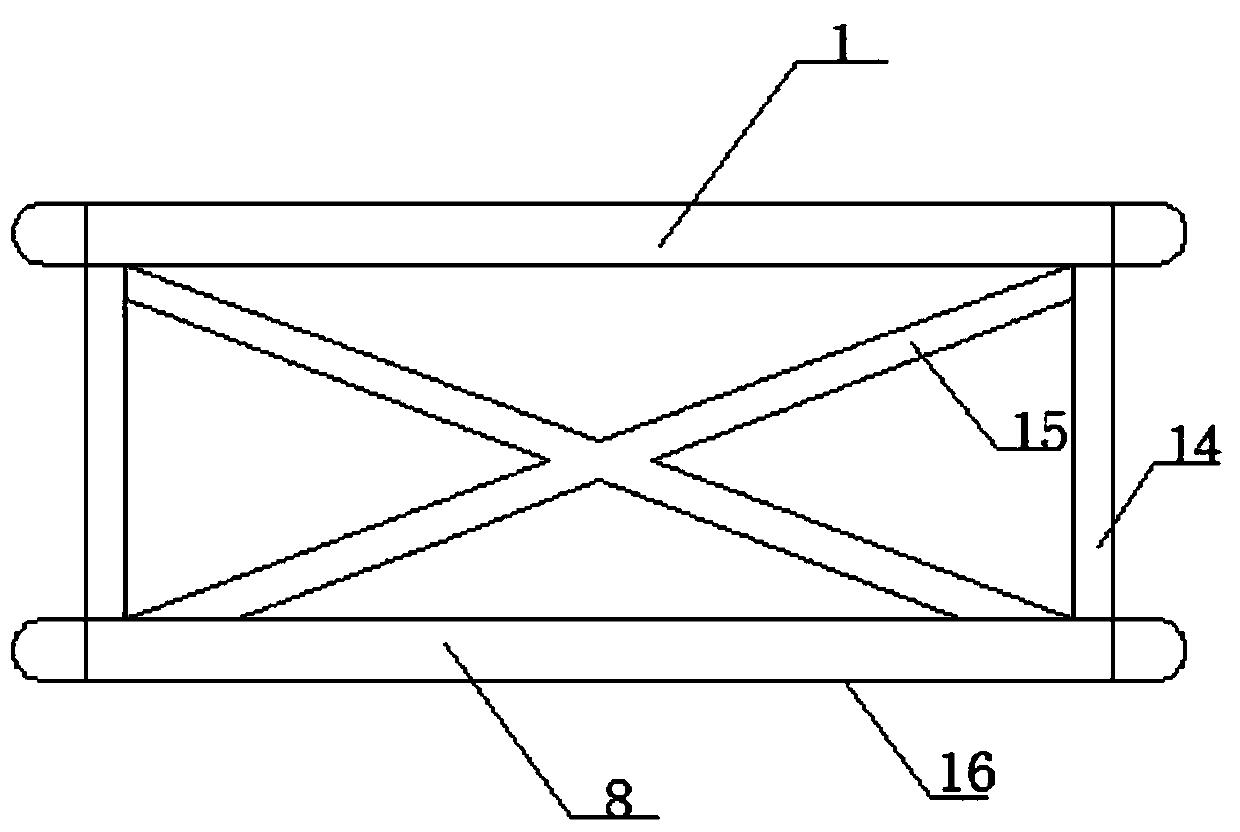

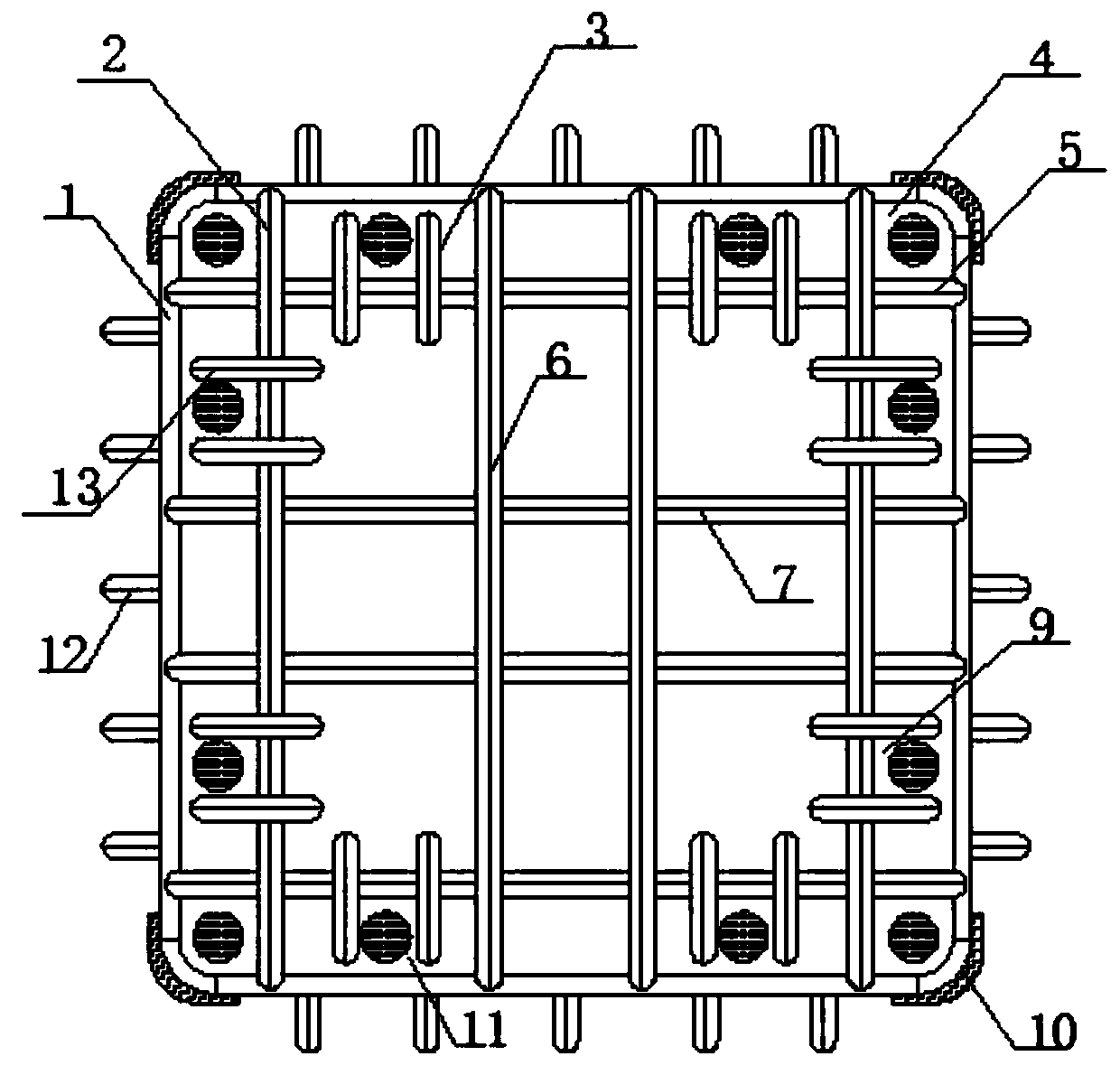

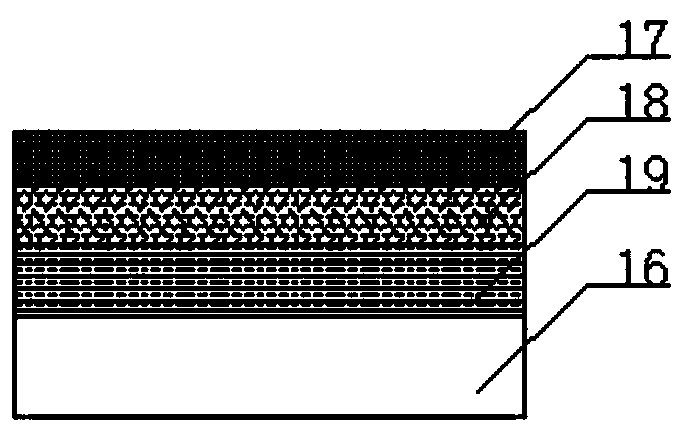

[0020] Such as Figure 1-3 As shown, a column bar positioning hoop with high-precision positioning includes a column bar positioning hoop body 16 consisting of a top column bar positioning surface 1, a bottom column bar positioning surface 8, a connecting column bar 14 and X-shaped stiffeners 15, the top column locating surface 1 is located at the top of the column locating hoop body 16 and the bottom column locating surface 8 is located at the bottom of the column locating hoop body 16, the top column locating surface 1 and the bottom column The rib positioning surfaces 8 are connected by connecting column ribs 14, the top ends of the top column rib positioning surface 1 and the bottom column rib positioning surface 8 are welded to connect the transverse ribs 5, the top column rib positioning surface 1 and the bottom column ribs are positioned The other ends of the top of the surface 8 are welded with vertical connecting ribs 2 perpendicular to the connecting horizontal ribs 5...

Embodiment 2

[0027] Such as Figure 1-3 As shown, a high-precision positioning column bar positioning hoop includes a column bar positioning hoop body 16 consisting of a top column bar positioning surface 1, a bottom column bar positioning surface 8, a connecting column bar 14 and X-shaped stiffeners 15, the top column locating surface 1 is located at the top of the column locating hoop body 16 and the bottom column locating surface 8 is located at the bottom of the column locating hoop body 16, the top column locating surface 1 and the bottom column The rib positioning surfaces 8 are connected by connecting column ribs 14, the top ends of the top column rib positioning surface 1 and the bottom column rib positioning surface 8 are welded to connect the transverse ribs 5, the top column rib positioning surface 1 and the bottom column ribs are positioned The other ends of the top of the surface 8 are welded with vertical connecting ribs 2 perpendicular to the connecting horizontal ribs 5, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com