Annulus mechanical isolation packer for oil and gas wells

An annulus machine and packer technology, which is used in sealing/packing, wellbore/well components, earth-moving drilling, etc., and can solve the problems of unfavorable drilling and workover, multi-diameter tools, limited scale and capacity of reconstruction, etc. , to achieve the effect of easy unsealing and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

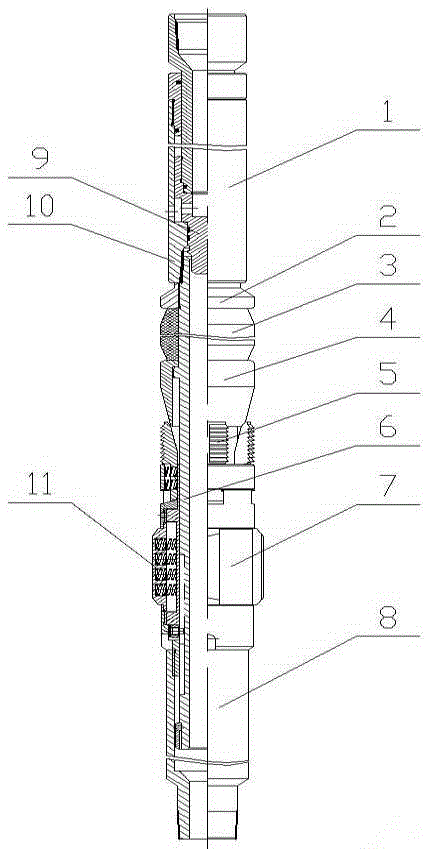

[0026] The invention discloses an annulus mechanical sealing packer for oil and gas wells, comprising a pressure balancing device and a setting and sealing device, the pressure balancing device includes a pressure balancing valve 1; the setting and sealing device includes a rubber cylinder seat 2 , rubber tube 3, cone 4, slips 5, central tube 6, centering seat 7 and lower joint 1-8; from top to bottom, the pressure balance valve 1, central tube 6, rubber tube seat 2, rubber tube 3, Cone 4, slips 5, centering seat 7, and lower joint 1-8 are sequentially connected; the pressure balance valve 1 is connected to the upper end of the center pipe 6 and is located on the rubber cartridge seat 2; the sealing head 9 in the pressure balance valve 1 It is plug-fitted with the lower joint 10 in the pressure balance valve 1.

Embodiment 2

[0028] Refer to the attached figure 1 , the best embodiment of the present invention is: including a pressure balance device and a setting and sealing device, the pressure balancing device includes a pressure balance valve 1; the setting and sealing device includes a rubber cylinder seat 2, a rubber cylinder 3, and a cone 4 , slips 5, center pipe 6, centering seat 7 and lower joint 8; pressure balance valve 1, center pipe 6, rubber cartridge seat 2, rubber cartridge 3, cone 4, slips 5, The centralizing seat 7 and the lower joint 18 are sequentially connected; the pressure balance valve 1 is connected to the upper end of the center pipe 6 and is located on the rubber cartridge seat 2; Connector two 10 plug-in type mating. The upper end of the central pipe 6 is threadedly connected to the lower joint 10 of the pressure balance valve 1 . The central tube 6 is provided with a keyway. The pressure balance device and the setting and isolation device are connected by threads from ...

Embodiment 3

[0032]The process of the present invention: the present invention is composed of the following structures in actual use: the uppermost end is a coiled tubing, and the following are sequentially connected to a CT connector, a mechanical handle, a hydraulic handle, a centralizer, a spray gun, a pressure balance valve 1, and a seal The lower end of the pipe string is connected to the guide shoe; the above-mentioned parts are connected by threads, and the above-mentioned parts are formed into a pipe string, and the coiled tubing vehicle is lowered to a certain depth in the downhole casing of the oil and gas well, and positioned through the coupling The packer is positioned, and the string is lifted up and down to set the packer to seal the lower layer that has been constructed. At the same time, the spray gun set on the upper part of the packer is also aimed at the pre-perforation and fracturing and acidizing layer. At this time, the pressure The balance valve 1 closes the internal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com