Fan blade mechanism of wind driven generator

A technology of wind-driven generators and blades, applied to wind-driven engines, wind-powered engines at right angles to the wind direction, engines, etc., can solve problems such as difficult installation, high difficulty in manufacturing, installation and maintenance, and low utilization efficiency, and achieve The effect of high utilization rate of wind energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with embodiment.

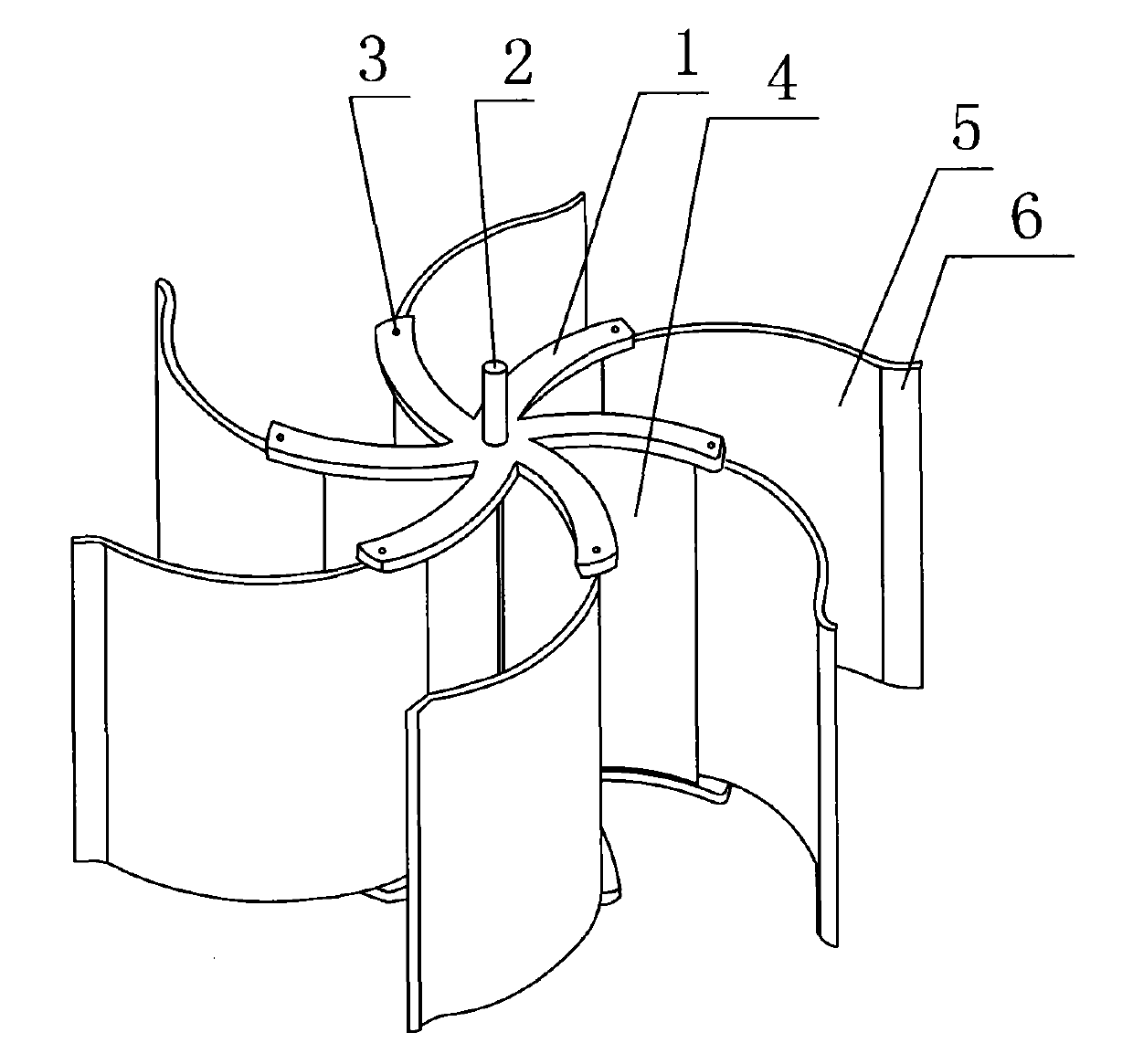

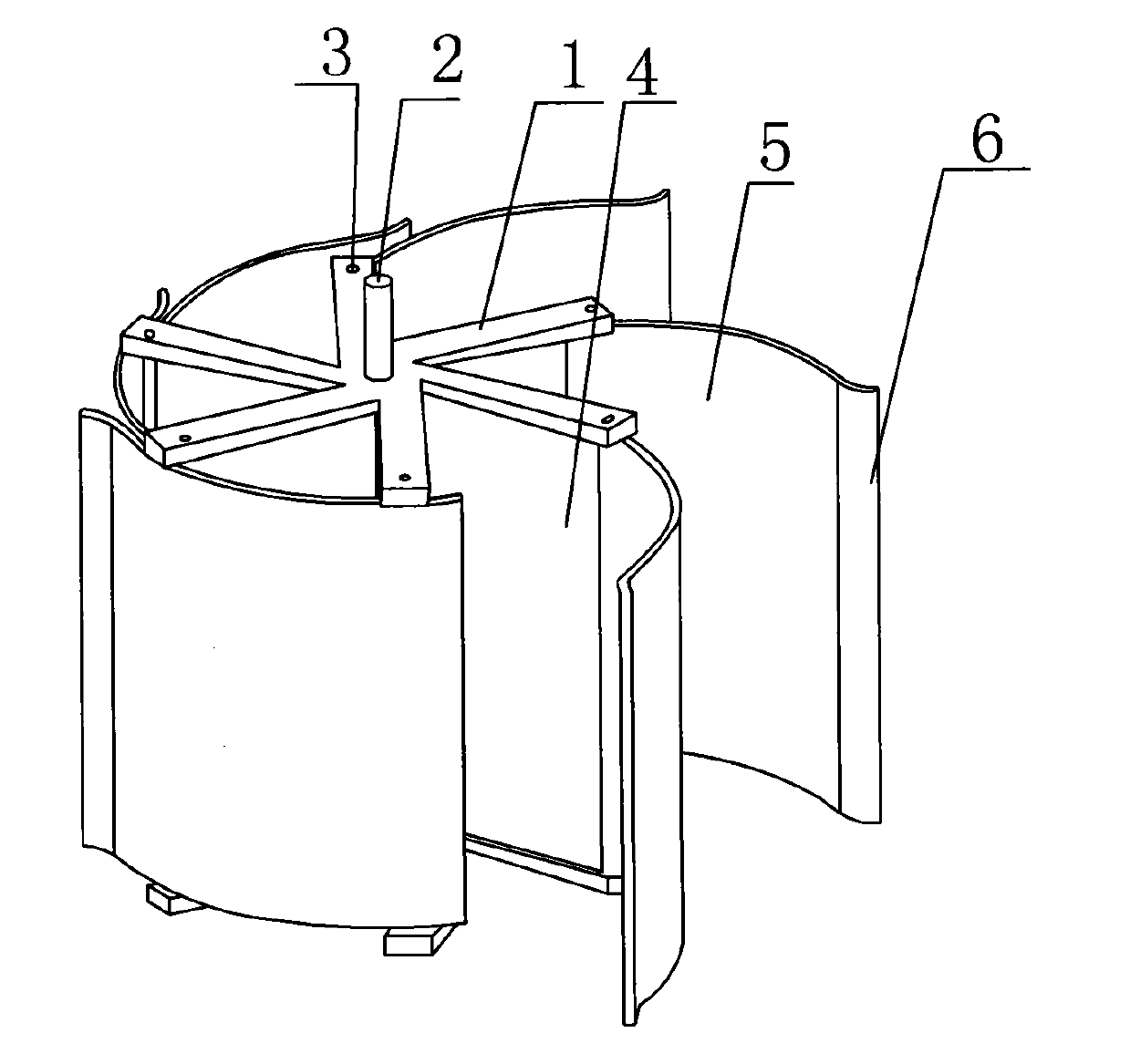

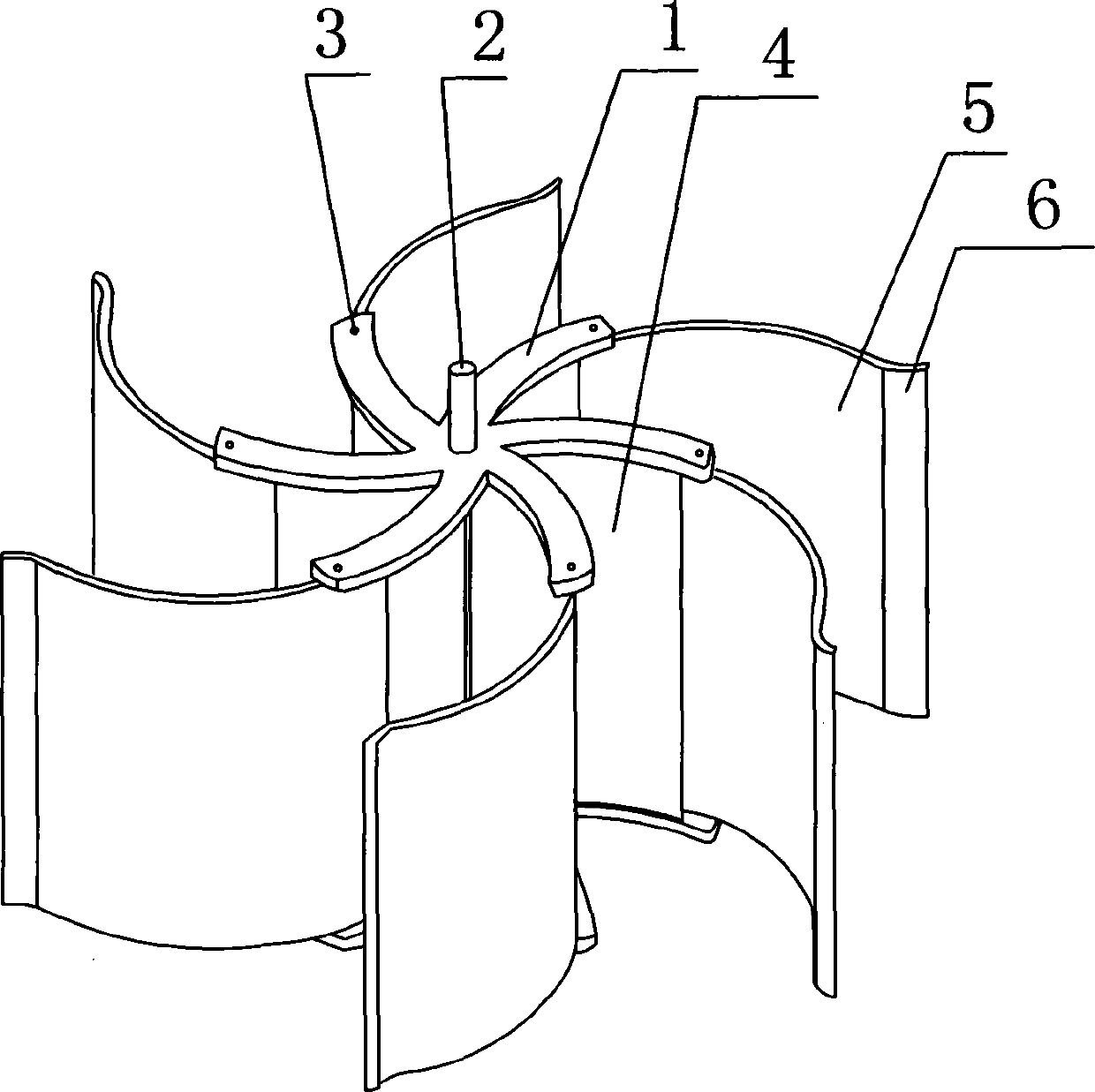

[0019] like figure 1 , figure 2 As shown, the fan blade mechanism of the wind power generator of the present invention is mainly composed of a fixed bracket 1, a central shaft 2, a central pillar, six fixed blades 4 and movable blades 5 that are axially connected with the fixed bracket shaft 3, and the fixed bracket 1 It is composed of arc-shaped rods that are equicircumferential and radial, and there are two upper and lower ones. The fixed bracket shaft 3 is arranged at each radial end of each fixed bracket 1, and the fixed blade 4 is arranged between the central axis 2 and the fixed bracket shaft 3. The movable vane 5 takes the fixed support shaft 3 as the movable axis. The movable vane 5 is arc-shaped, and the outer end is provided with an outwardly curved wind guide edge 6; the inner side of the movable vane 5 protrudes slightly, and fits with the joint of the fixed vane 4; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com