Light irradiating apparatus for exposure apparatus, lighting control method thereof, exposure apparatus, and substrate

A technology of light irradiation device and exposure device, which can be applied in the direction of photolithography process exposure device, pattern surface photolithography process, microlithography exposure equipment, etc. problem of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

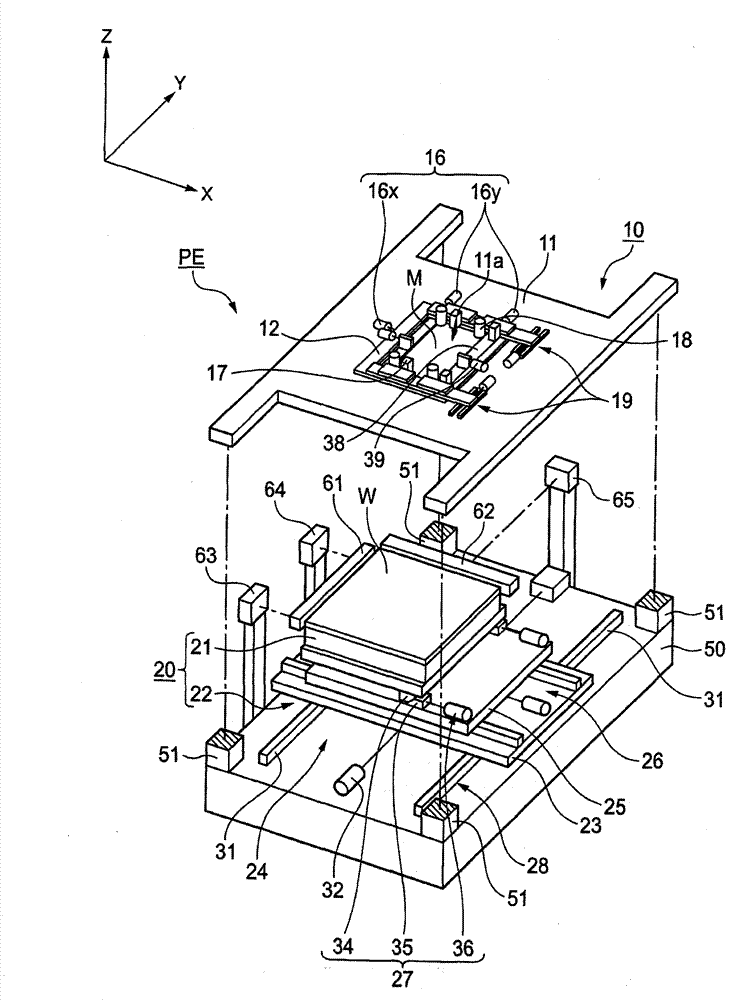

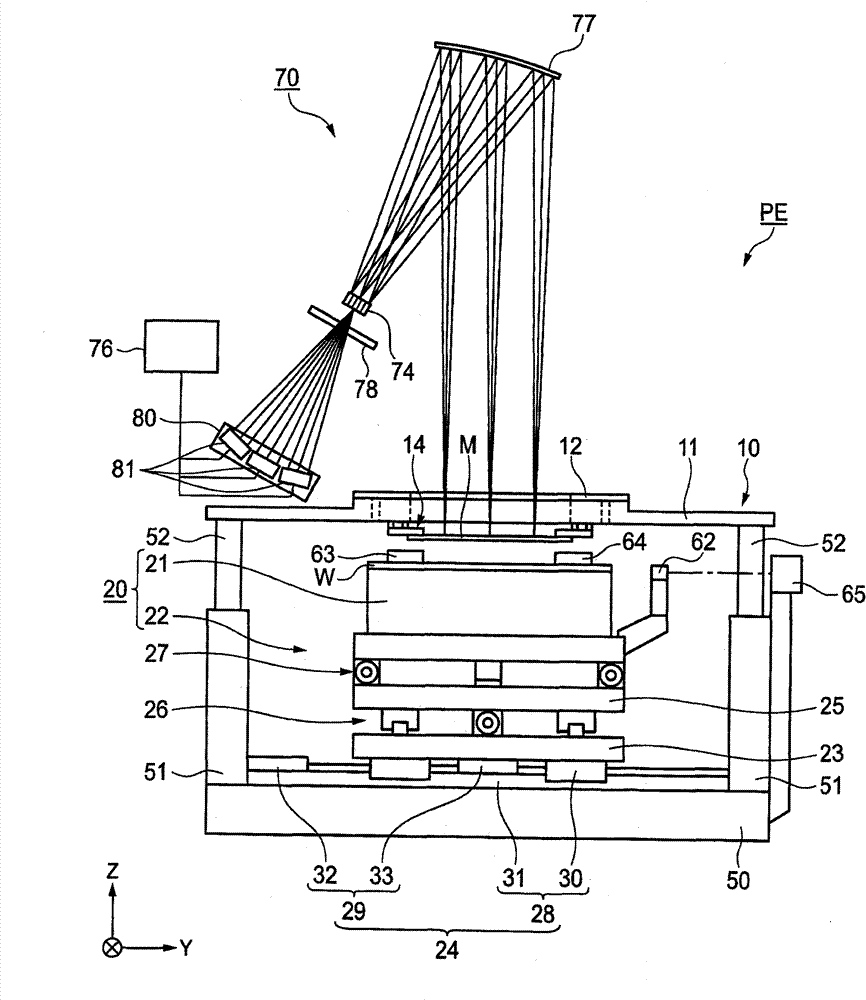

[0113] Such as figure 1 with figure 2 As shown, the partitioned successive proximity exposure apparatus PE of the first embodiment has a mask stage 10 holding a mask M, a substrate stage 20 holding a glass substrate (material to be exposed) W, and an illumination optical system for irradiating pattern exposure light. System 70.

[0114] Furthermore, the glass substrate W (hereinafter, simply referred to as "substrate W") is placed opposite to the mask M, and the surface (the side facing the mask M) where the pattern drawn on the mask M should be photolithographically coated Sensitizer.

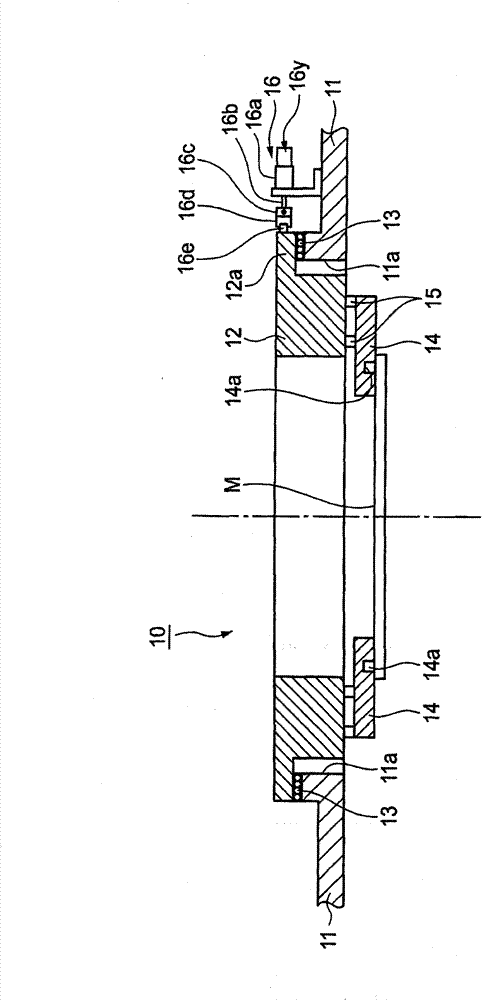

[0115] The mask table 10 has: a mask table base 11 with a rectangular opening 11a formed in the center; The mask holding frame 12 of the mask holding part; it is arranged on the upper surface of the mask table base 11, and the mask driving is used to move the mask holding frame 12 in the X-axis, Y-axis, and θ directions to adjust the position of the mask M Agency16.

[0116] The mask sta...

no. 2 approach

[0177] Next, regarding the proximity scanning exposure apparatus according to the second embodiment of the present invention, refer to Figure 20 ~ Figure 25 Be explained.

[0178] Proximity scanning exposure device 101 such as Figure 23 As shown, a substantially rectangular substrate W conveyed in a predetermined direction is irradiated with exposure light L through a plurality of masks M on which a pattern P is formed while approaching the mask M, and the pattern P is etched on the substrate W. That is, this exposure apparatus 101 employ|adopts the scanning exposure method which performs photolithography, moving the board|substrate W with respect to several mask M. In addition, the size of the mask used in this embodiment is set to 350 mm x 250 mm, and the length of the X direction of the pattern P corresponds to the length of the X direction of an effective exposure area.

[0179] Such as Figure 20 with Figure 21 As shown, the proximity scanning exposure apparatus 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com