Knocking detection device for internal combustion engine

A detection device, internal combustion engine technology, applied in the direction of internal combustion engine testing, measuring devices, engine testing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0058] figure 1 It is an overall configuration diagram of an internal combustion engine (hereinafter referred to as "engine") and its control device according to an embodiment of the present invention. For example, a throttle valve 3 is disposed in the middle of an intake pipe 2 of a four-cylinder engine 1 . The throttle valve 3 is connected to a throttle opening sensor 4 that detects a throttle opening TH, and a detection signal from the sensor 4 is supplied to an electronic control unit (hereinafter referred to as “ECU”) 5 .

[0059] For each cylinder, a fuel injection valve 6 is provided slightly upstream of an unillustrated intake valve located between the engine 1 and the throttle valve 3 and in the intake pipe 2, and each injection valve is connected to an unillustrated intake valve. The fuel pump is connected and electrically connected to the ECU 5 , and the opening timing of the fuel injection valve 6 is controlled based on a signal from the ECU 5 . A spark plug 7 is...

no. 2 Embodiment approach

[0137] In this embodiment, the knock determination processing in the first embodiment ( Figure 8 ) changed to Figure 18 treatment shown. Except for the points described below, it is the same as the first embodiment.

[0138] exist Figure 18 In the processing shown, first, noise removal processing is performed on the intensity parameter KMAP before binarization, and the corrected intensity parameter JKMAPI is calculated (step S12a), the corrected intensity parameter JKMAPI is binarized, and the corrected binarized intensity parameter is calculated JKMAP (step S11b).

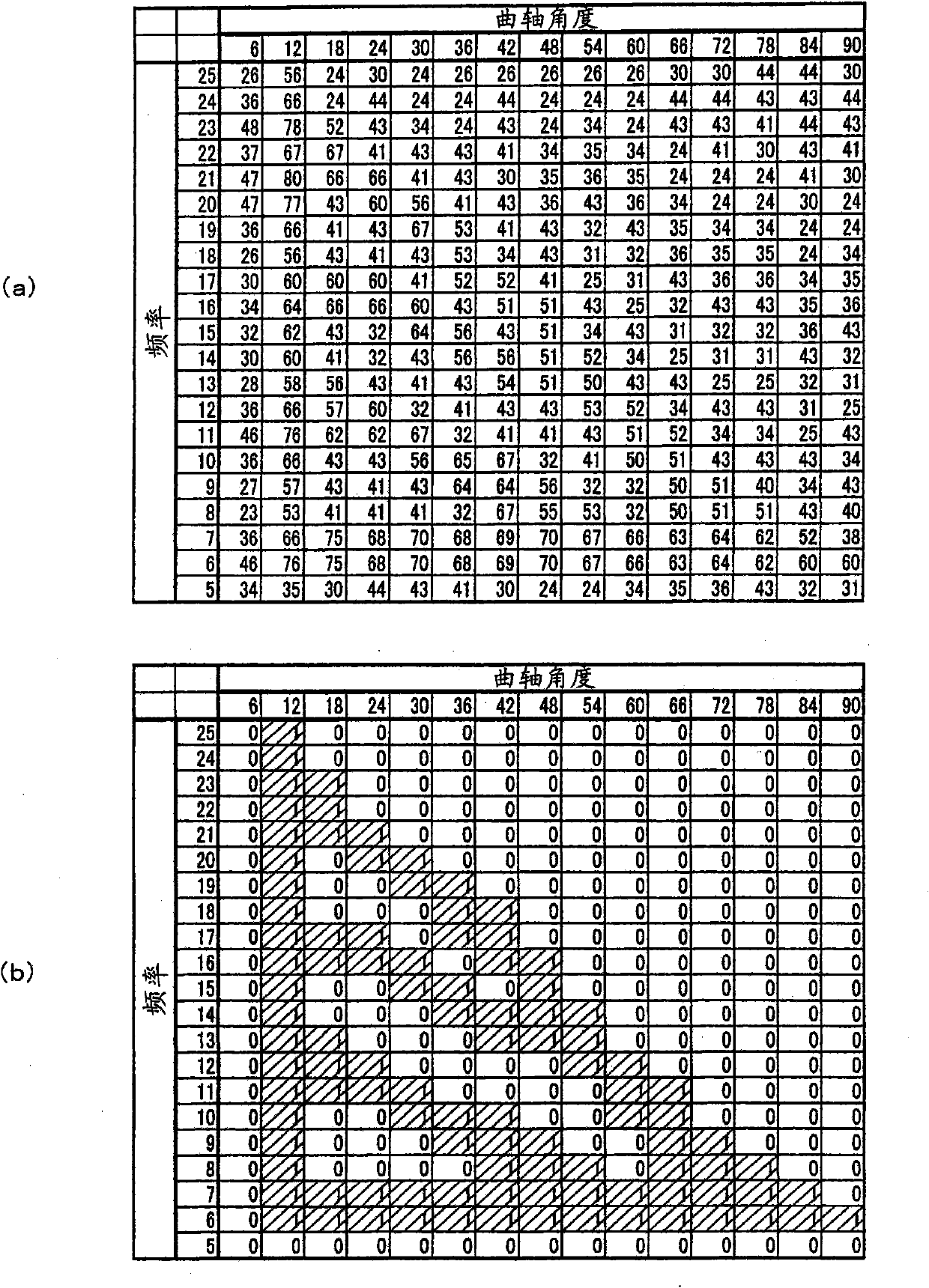

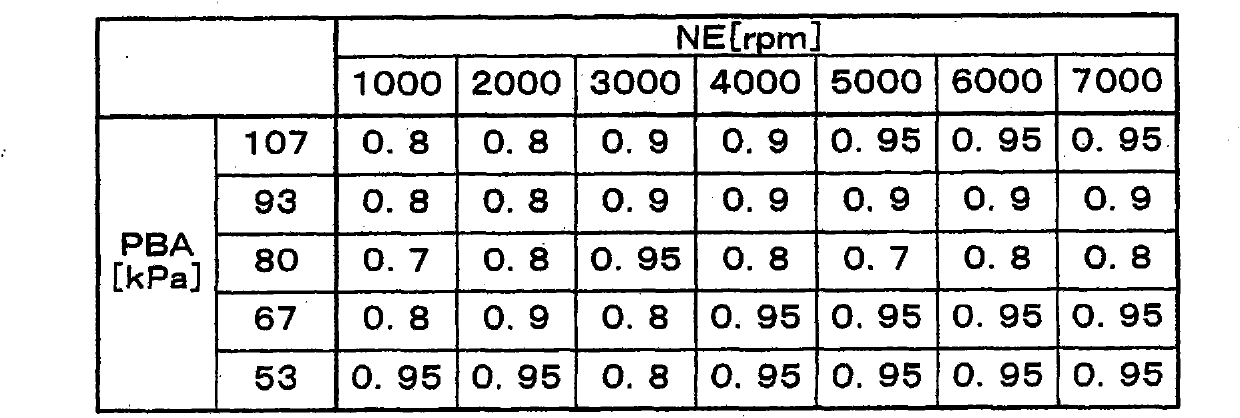

[0139] Figure 19 (a) shows an example of the frequency spectrum sequence map in this embodiment, Figure 19 (b) is a figure which shows an example of the noise map in this embodiment, and the noise learning value which is not binarized is set. The noise removal process is done by starting from Figure 19 Subtract from each map value of the frequency spectrum timing map of (a) Figure 19 (b) for the noi...

no. 3 Embodiment approach

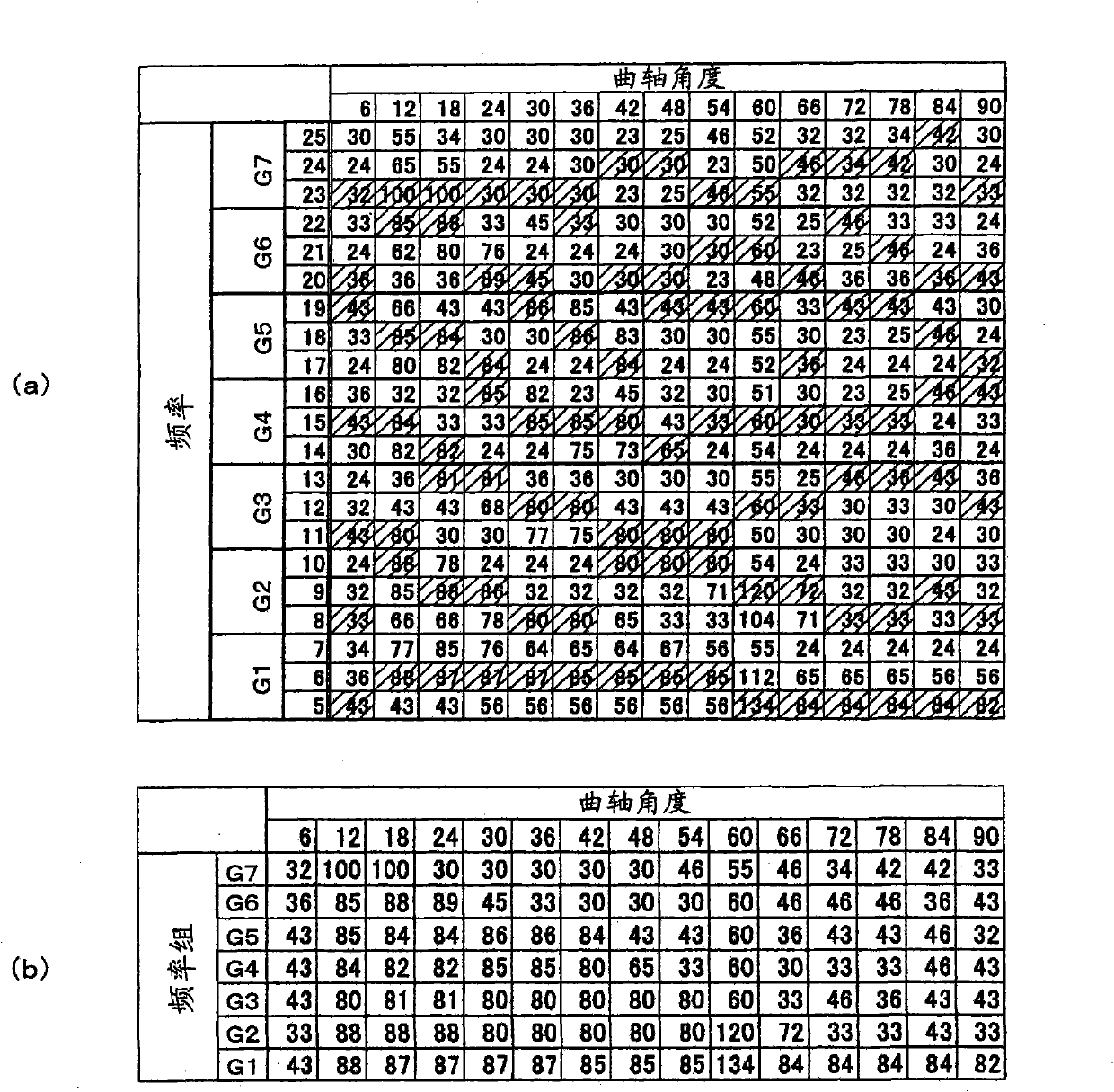

[0160] This embodiment is configured by dividing (grouping) 21 frequencies from 5 kHz to 25 kHz into seven frequency groups G1 to G7 consisting of three frequencies, and grouping the representative value of the intensity parameter KMAP corresponding to one sampling timing. The strength parameter GKMAP is set to the maximum value within the frequency group. By performing grouping in this way at the beginning, the number of data to be subjected to noise removal processing, binarization processing, and fitness rate calculation processing is reduced to 1 / 3, and the calculation load can be greatly reduced. In addition, it is the same as the second embodiment except for the points described below.

[0161] Figure 25 is a diagram for explaining grouping. Such as Figure 25 As shown in (a), frequencies 5kHz, 6kHz, 7kHz correspond to frequency group G1; frequencies 8kHz, 9kHz, 10kHz correspond to frequency group G2; frequencies 11kHz, 12kHz, 13kHz correspond to frequency group G3; fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com