Control valve trim and seal

A technology of sealing rings and sealing bands, which is applied in the field of control valves and can solve problems such as product quality impact and unintentional leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

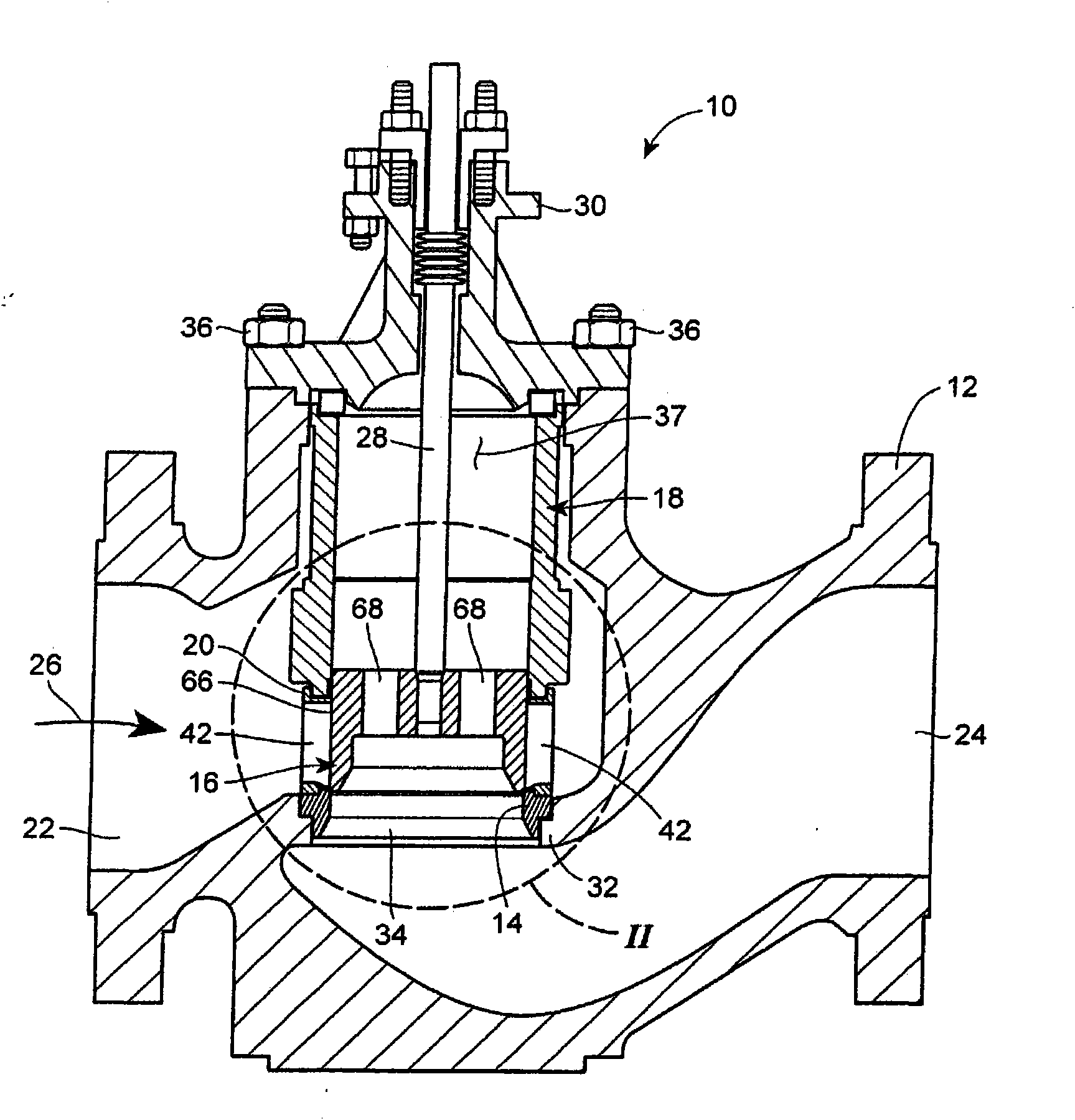

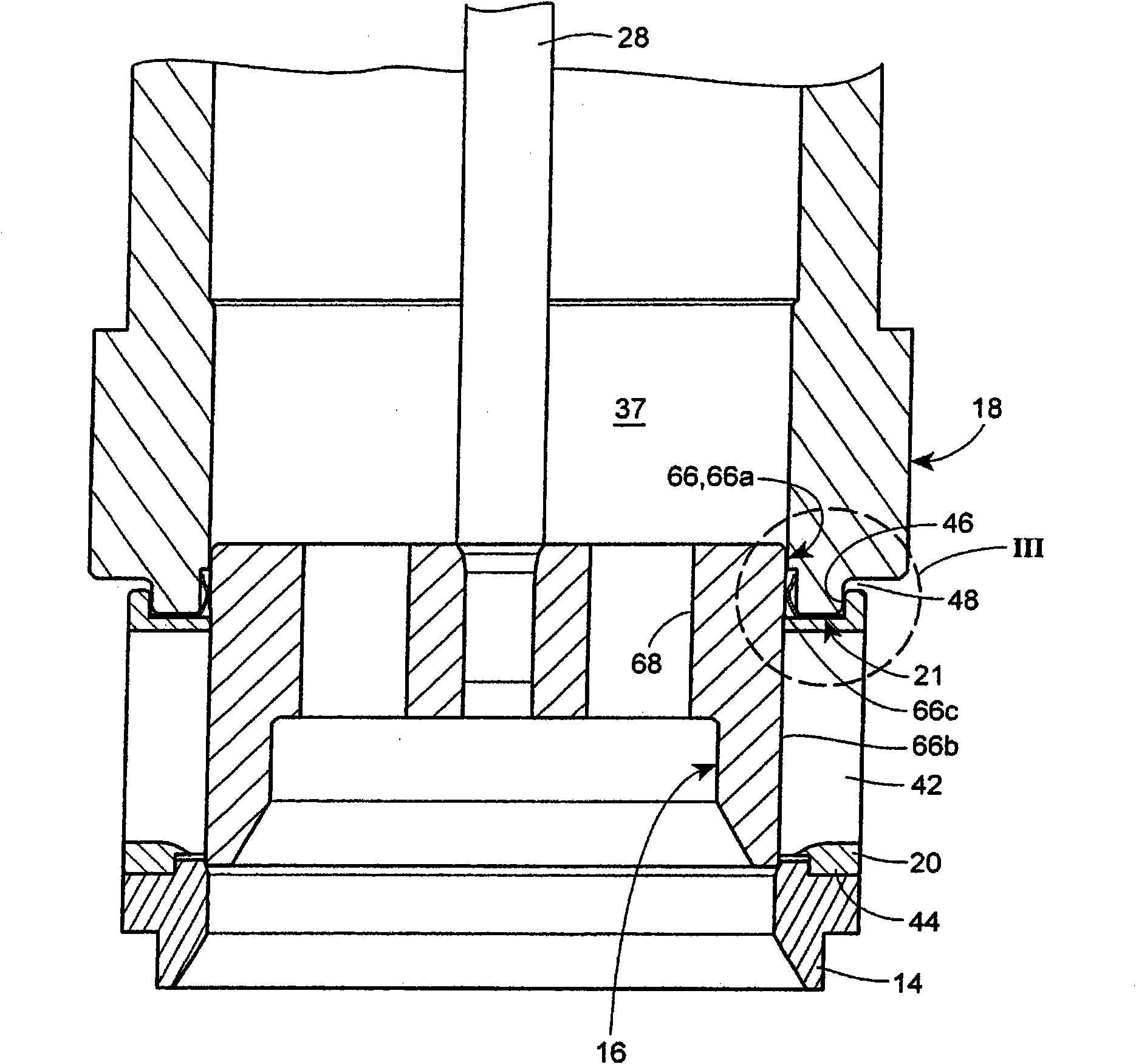

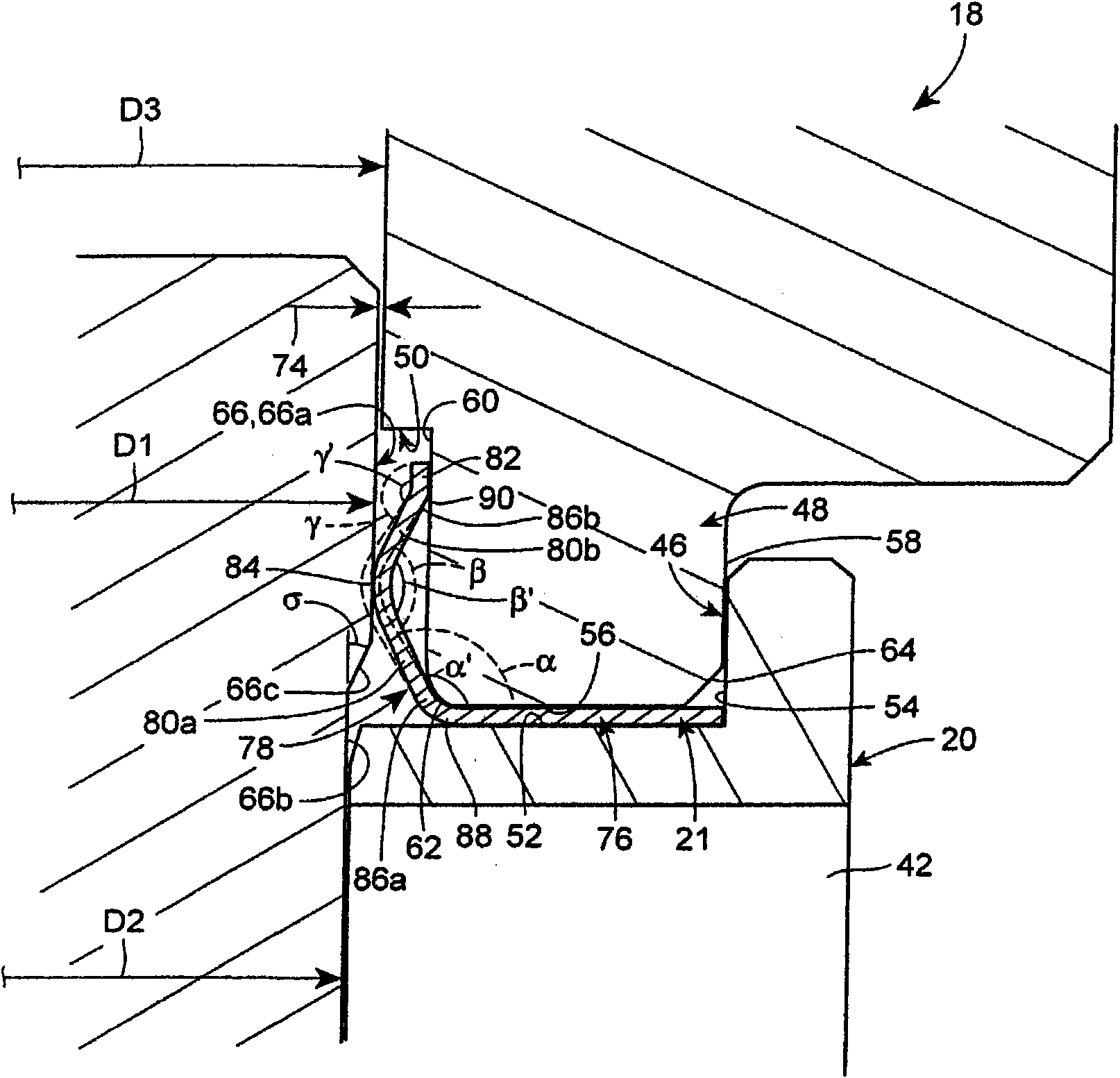

[0008] figure 1 One embodiment of a control valve 10 constructed in accordance with the principles of the present invention is shown. The control valve 10 generally includes a valve body 12, a bonnet 30, a cage retainer 18, a cage 20, a sealing ring 21 (in figure 2 shown in), the valve plug 16 and the valve seat 14. Valve body 12 defines an inlet aperture 22 , an outlet aperture 24 , and a fluid flow path 26 extending between inlet aperture 22 and outlet aperture 24 . The valve plug 16 is coupled to the end of a valve stem 28 which extends through a valve cap 30 and is adapted to be coupled to an actuator (not shown). The actuator controls the spool 16 in the closed position (in figure 1 shown in ) and an open position (not shown) in which the valve plug engages the valve seat 14 to define a primary seal and an open position (not shown) in which the valve plug clears the valve seat 14 . Seal ring 21 provides a secondary seal between cage retainer 18 and cage 20 . In the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap