Demoulding device with spring-piece type tapered pin anti-breaking mechanism

A demoulding device and oblique pin technology, which is applied in the field of injection molds, can solve problems such as over-tension fracture, achieve the effects of preventing over-tension fracture, easy design, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

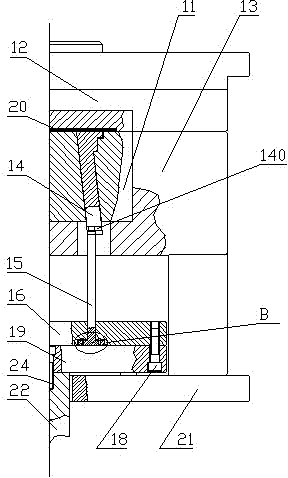

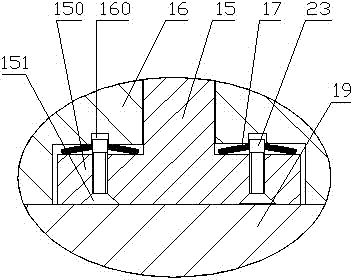

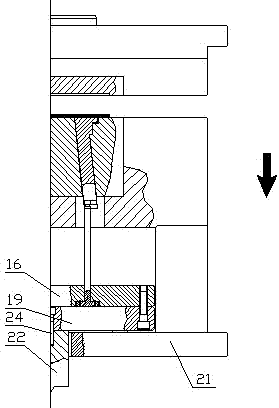

[0018] refer to Figure 1-8 As shown, a demoulding device with a shrapnel-type oblique pin breakage prevention mechanism includes a movable mold 13 with a movable mold core 11 having an oblique pin through hole 110, and a square-shaped oblique pin is installed in the oblique pin through hole 110. Pin 14, the positioning surface A of the upper end block of the oblique pin 14 is matched with the upper end of the oblique pin through hole 110 with high precision, and the lower end of the oblique pin 14 is provided with a transverse chute 140, and the chute 140 is connected with the upper end of the longitudinal push rod 15 The flange 150 at the lower end of the push rod 15 is installed on the push plate fixing plate 16 with a stepped hole, and an annular spring piece 17 with an arc-shaped section is placed between the lower end flange 150 of the push rod 15 and the push plate fixing plate 16, The push plate fixing plate 16 is fixed with the push plate 19 by the bolt 18, and the pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com