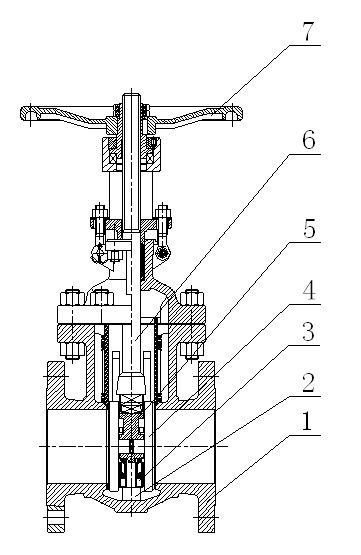

Parallel double-supporting plate gate valve

A double-support gate and support plate technology, applied in sliding valves, valve devices, engine components, etc., can solve problems such as easy failure, inability to open and close, support plate movement, etc., to improve service life, reduce friction, Anti-chafing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

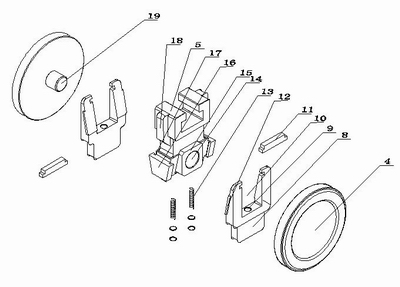

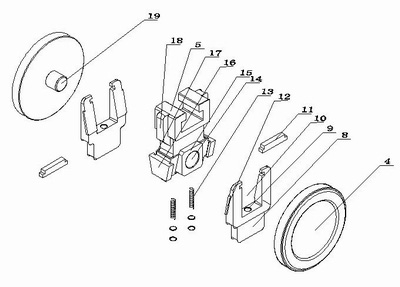

[0009] Referring to the accompanying drawings, this parallel double brace gate valve includes a valve body 1, a pair of valve plates 4, a valve stem 6, and a pair of braces 8, and a wedge pressure block 5 is provided between the pair of valve plates 4. The valve stem 6 is connected to the wedge pressing block 5, and the support plate 8 is arranged between the valve plate 4 and the wedge pressing block 5. The support plate 8 is provided with wings 12, and the wedge pressing block 5 is provided with a limit block 16, the limit block 16 is provided with a chute 17 matching with the wing 12, the two sides of the wedge pressure block 5 have bosses 15, and the two sides of the wedge pressure block 5 There is a through hole 14 at the center of the boss 15 on the side, and the valve plate 4 has a sliding shaft 19, and the valve plate 4 is installed in the through hole 14 through the sliding shaft 19, so the valve plate 4 is installed in the medium Can rotate under the active force, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com