Method for detecting surface profile of wire wheel for multiwire saw wire cutting

A technology of surface contour and wire cutting, applied in the direction of electric/magnetic contour/curvature measurement, electromagnetic measuring device, etc., can solve problems such as low accuracy, increased labor costs, and unimproved efficiency, and achieve high measurement accuracy, Easy to operate and excellent contour effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

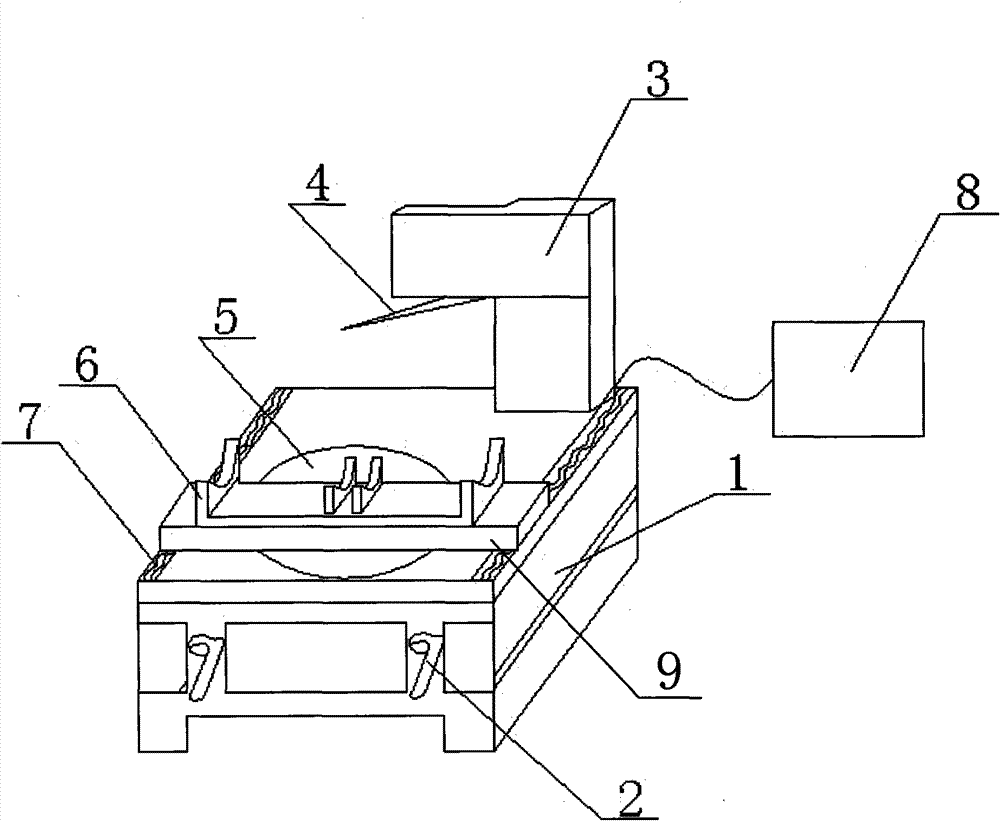

[0014] Embodiment 1, the detection device of the surface profile of the wire wheel of multi-wire saw wire cutting, the detection device used in the detection method comprises a frame 1, wherein: the frame 1 is provided with a rocking handle 2, a disc 5, a support 6, Guide rail 7, support 9; two guide rails 7 are symmetrically arranged on the frame 1, the bottom of the support 9 is slidingly connected with the frame 1 through the guide rail 7, the support 9 is provided with a bracket 6, and the bottom of the bracket 6 passes through the chute Slidingly connected with the support 9, the disc 5 is set at the lower part of the support 9, and the handle 2 is connected with the disc 5 through the crank arm and the connecting piece; the detection steps are as follows:

[0015] First, before measuring the wire wheel, adjust the level of the frame 1. There are four adjustable screws installed on the four corners of the frame 1, and the level of the test platform can be adjusted by adjus...

Embodiment 2

[0020] Embodiment 2, the detection device of the surface profile of the wire wheel for multi-wire saw wire cutting, wherein: the tester 3 is connected with the data analysis and processing device 8 through a signal line.

[0021] The data analysis and processing device 8 may be a computer and other devices.

[0022] working principle:

[0023] When measuring the wire wheel, firstly adjust the levelness of the frame 1. Four adjustable screws are respectively installed on the four corners of the frame 1, and the levelness of the test platform can be adjusted by adjusting the screws; then put the wire wheel to be measured on the On the bracket 6, according to the size of the wire wheel, select a bracket 6 of an appropriate size, slide the bracket 6 to a suitable position, and then fix it, drag the bracket 9 to the bottom of the tester 3, and the tester 3 is equipped with a test probe 4 and the display screen, put the needle of the test probe 4 on one end of the wire wheel, turn ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com