Dual-channel high-low-frequency ultrasonic attenuation signal detection device

A technology for signal attenuation and detection device, which is applied in measurement devices, suspension and porous material analysis, particle size analysis, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The structure and detection method of the present invention will be described in detail in conjunction with the accompanying drawings.

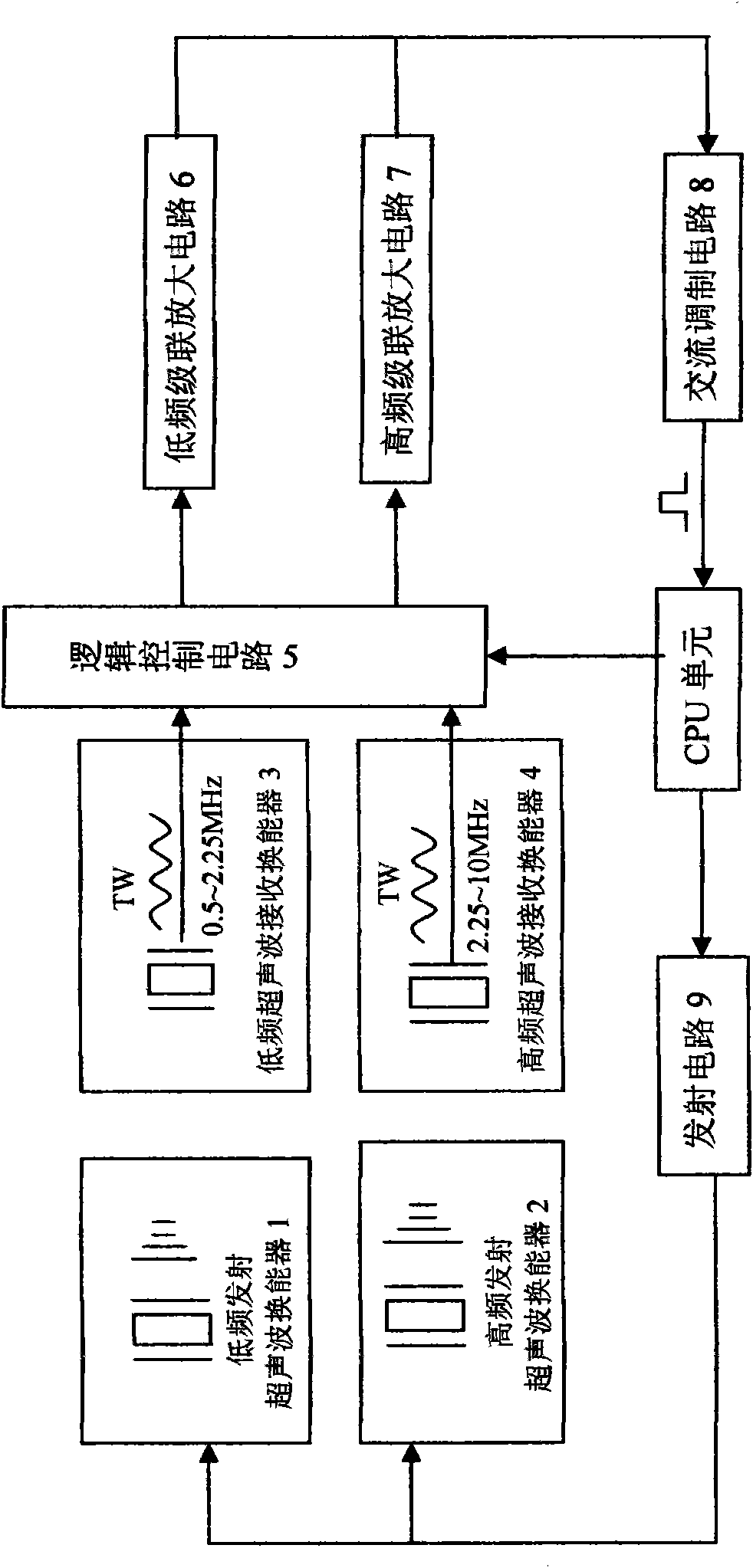

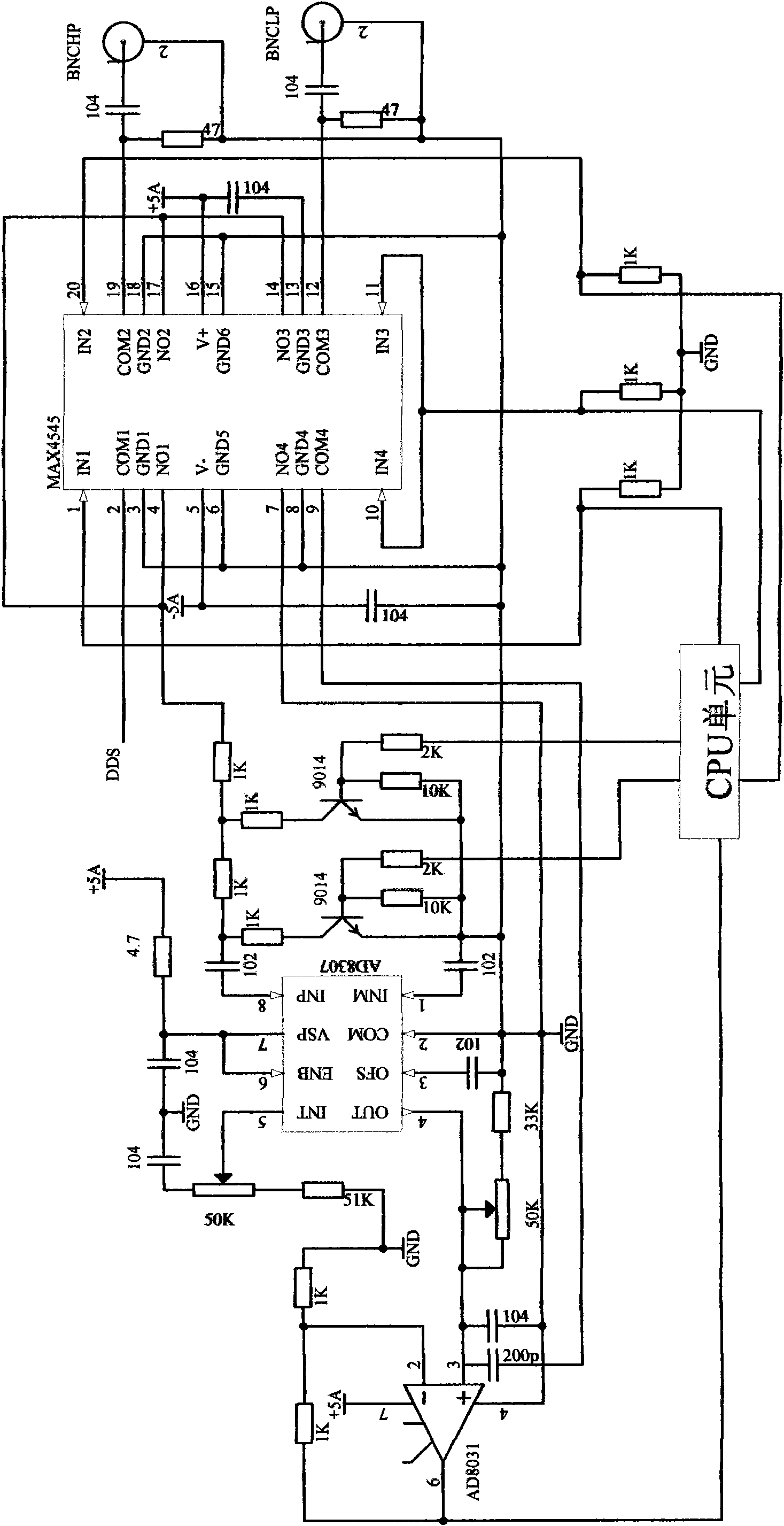

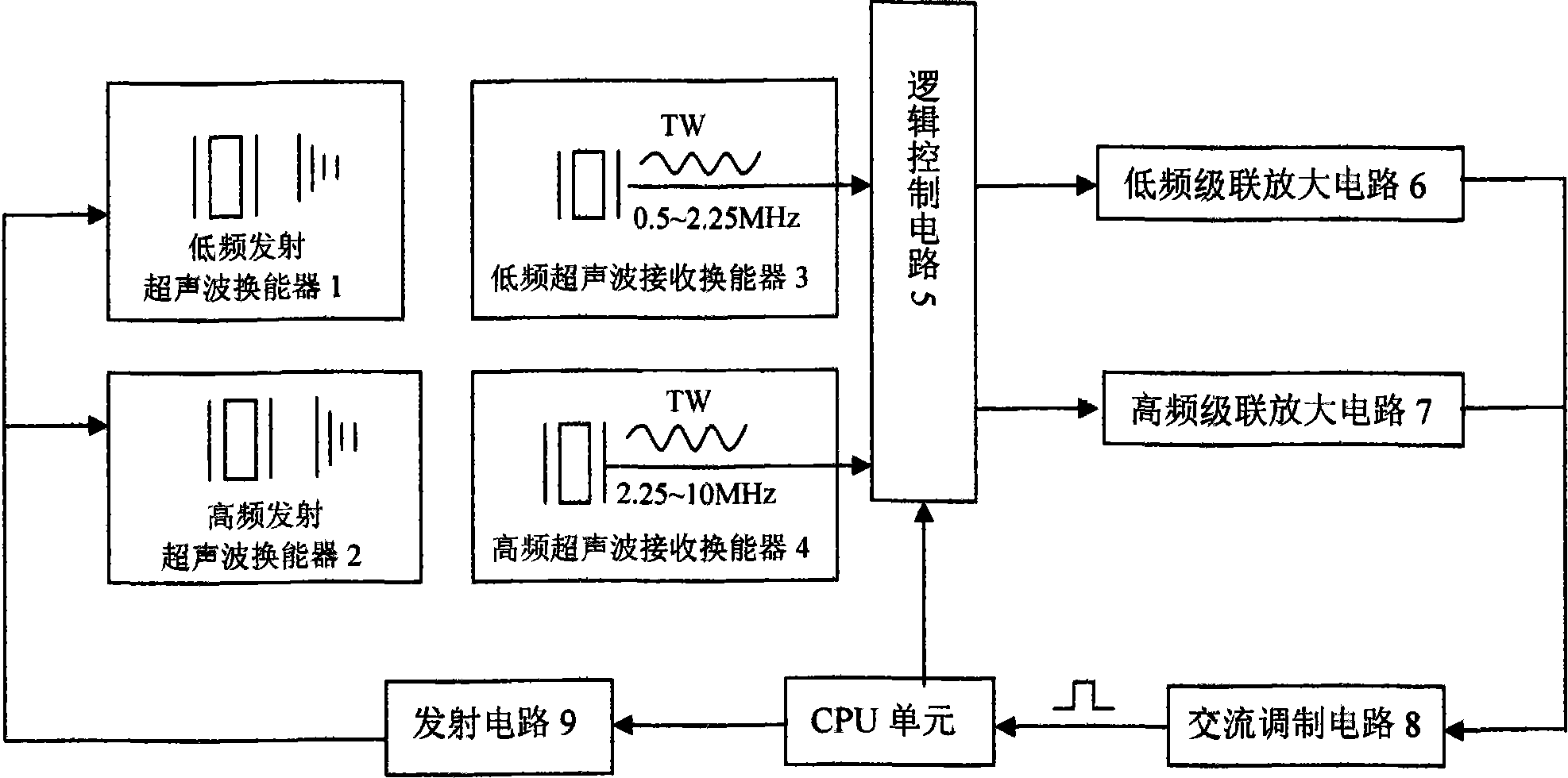

[0010] A dual-channel ultrasonic attenuation signal detection device, such as figure 1 As shown, the principle is: the CPU unit controls the transmitting circuit 9, and the transmitting circuit 9 is a prior art, that is, a high-frequency ultrasonic signal generator, the pulse is transmitted by the transmitting transducer, and then received by the receiving transducer, and the attenuation signal is sent to After the data is processed, it is sent to the CPU unit for judgment to determine whether the data meets the requirements for use. If it does not meet the requirements for use, the CPU unit will control the transmitting circuit again and repeat the same action. The specific working process is: the CPU unit time-sharingly controls the transmitting circuit 9 to generate a driving signal for driving the ultrasonic sensor. The driving sig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com