End mill with varying helix angles

An end mill and helix angle technology, applied in the field of end mills with variable helix angle, can solve the problem that the vibration of the milling cutter cannot be prevented, and achieve the effect of reducing the danger of vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

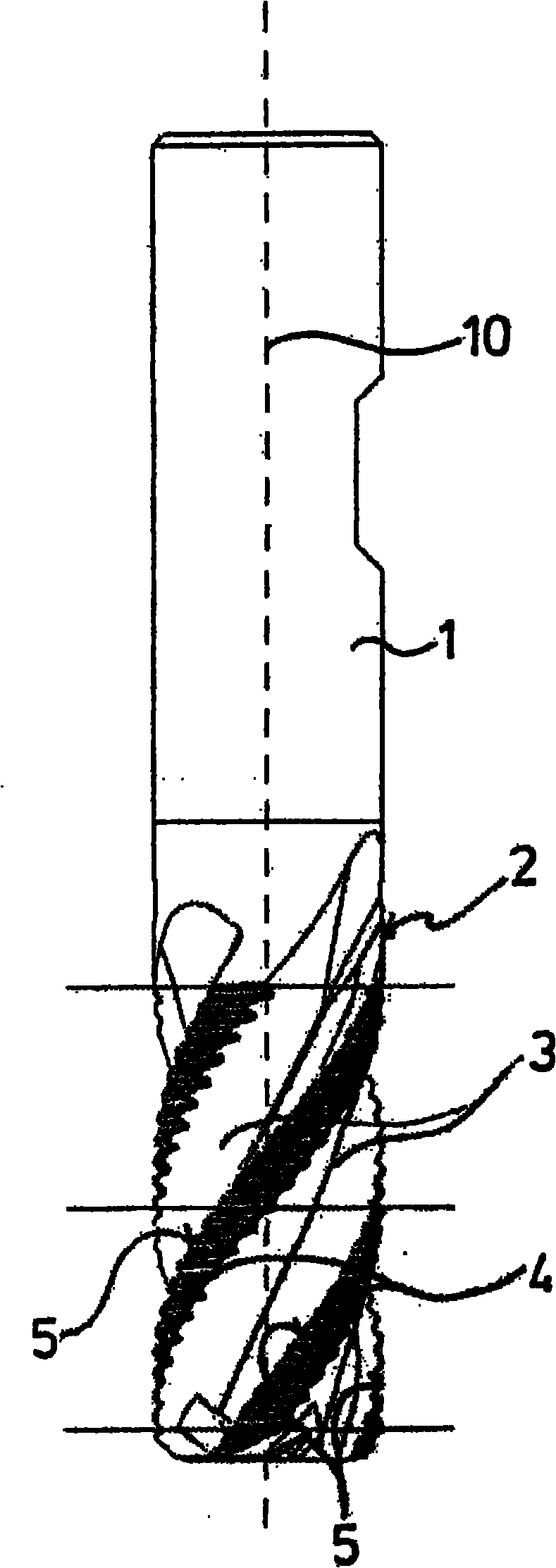

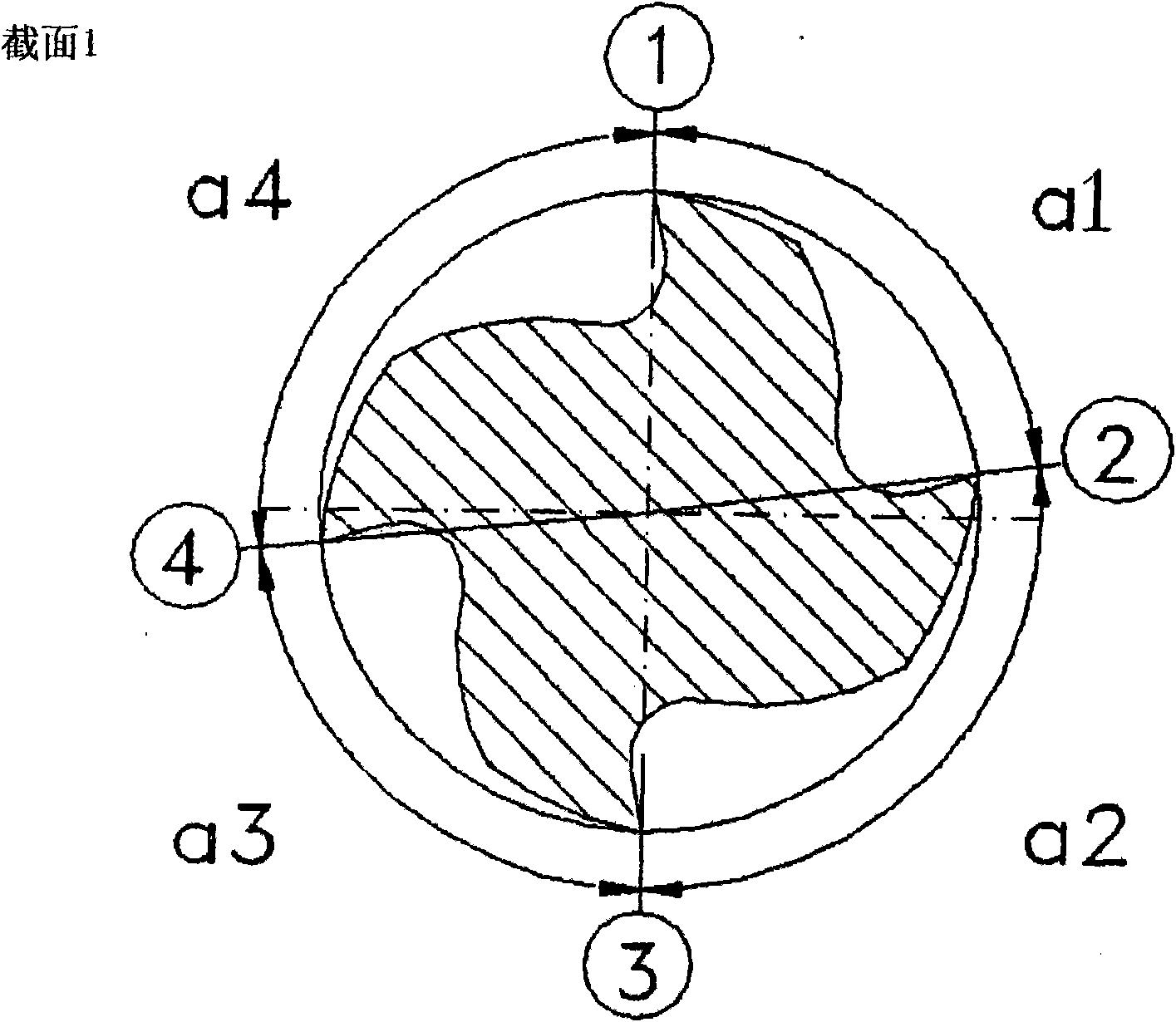

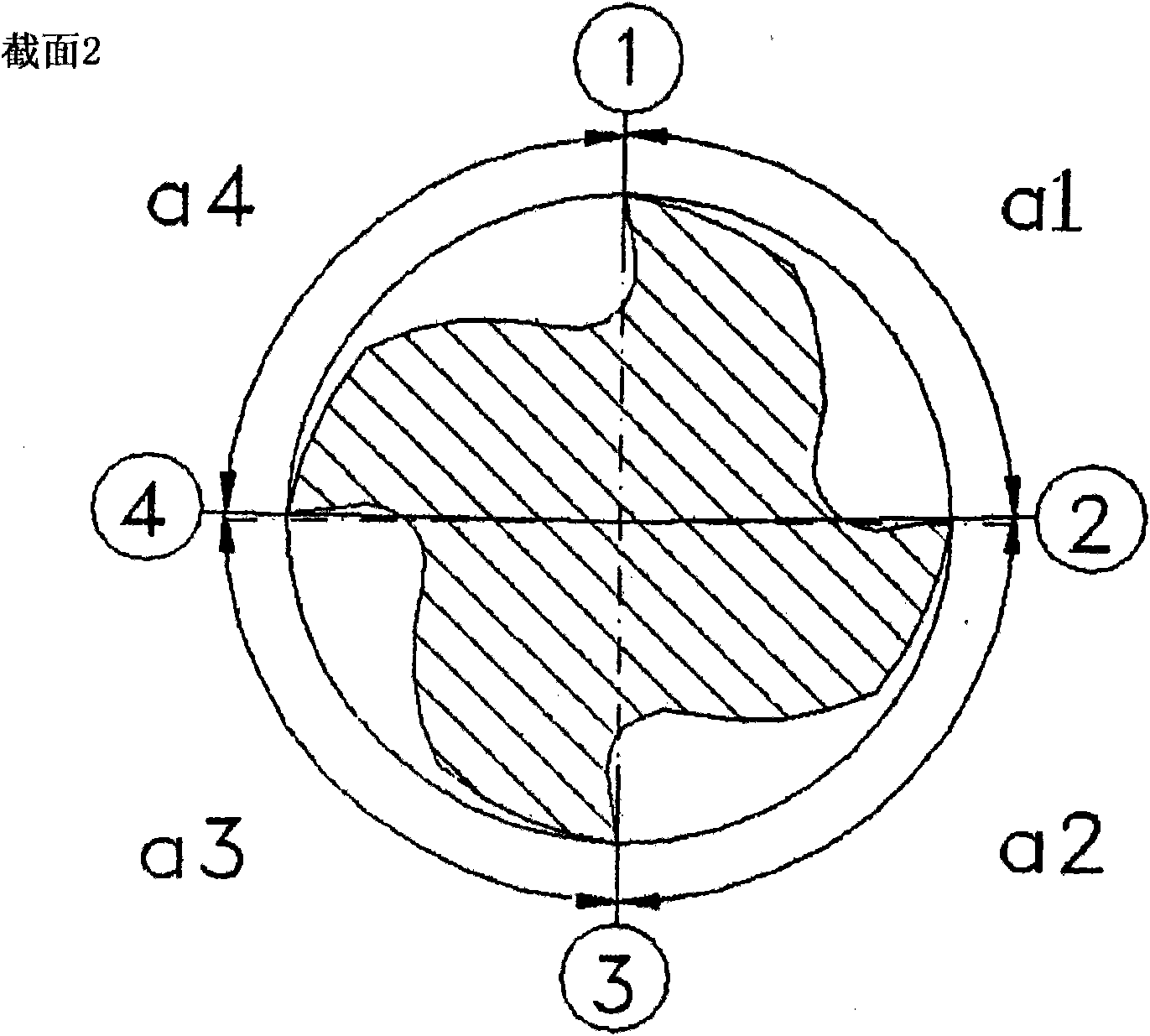

[0032] refer to figure 1 , shows an end mill comprising a mounting end 1 and a cutting portion 2 in plan view. Cutting part 2 includes chip flute 3 and cutting in the middle Figure 4 , each intermediate cutting figure defines a helical circular cutting edge 5 . The cutting edges extending helically around the axis 10 of the milling cutter show respectively different angles of inclination α and β with respect to the axis 10 . in all references to the same embodiment Figures 2 to 5 , different sections through the cutting portion 2 and perpendicular to the axis 10 are shown, while in Figure 5 In , the outer surface of the milling cutter, or rather only its cutting edge 5, is shown unfolded into one plane. figure 2 The locations of the cross-sections shown correspond to figure 1 The section line II-II in the image 3 The section shown in the corresponding figure 1 Section line III-III in, and Figure 4 The section shown in the corresponding figure 1 Section line IV-I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com