Color display transparent film coating member and manufacturing method thereof

A color display and film-coated technology, which is applied to chemical instruments and methods, instruments, layered products, etc., can solve the problems of excessive contrast and single color, achieve color diversification, increase colorfulness, and break through the limitations of appearance sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

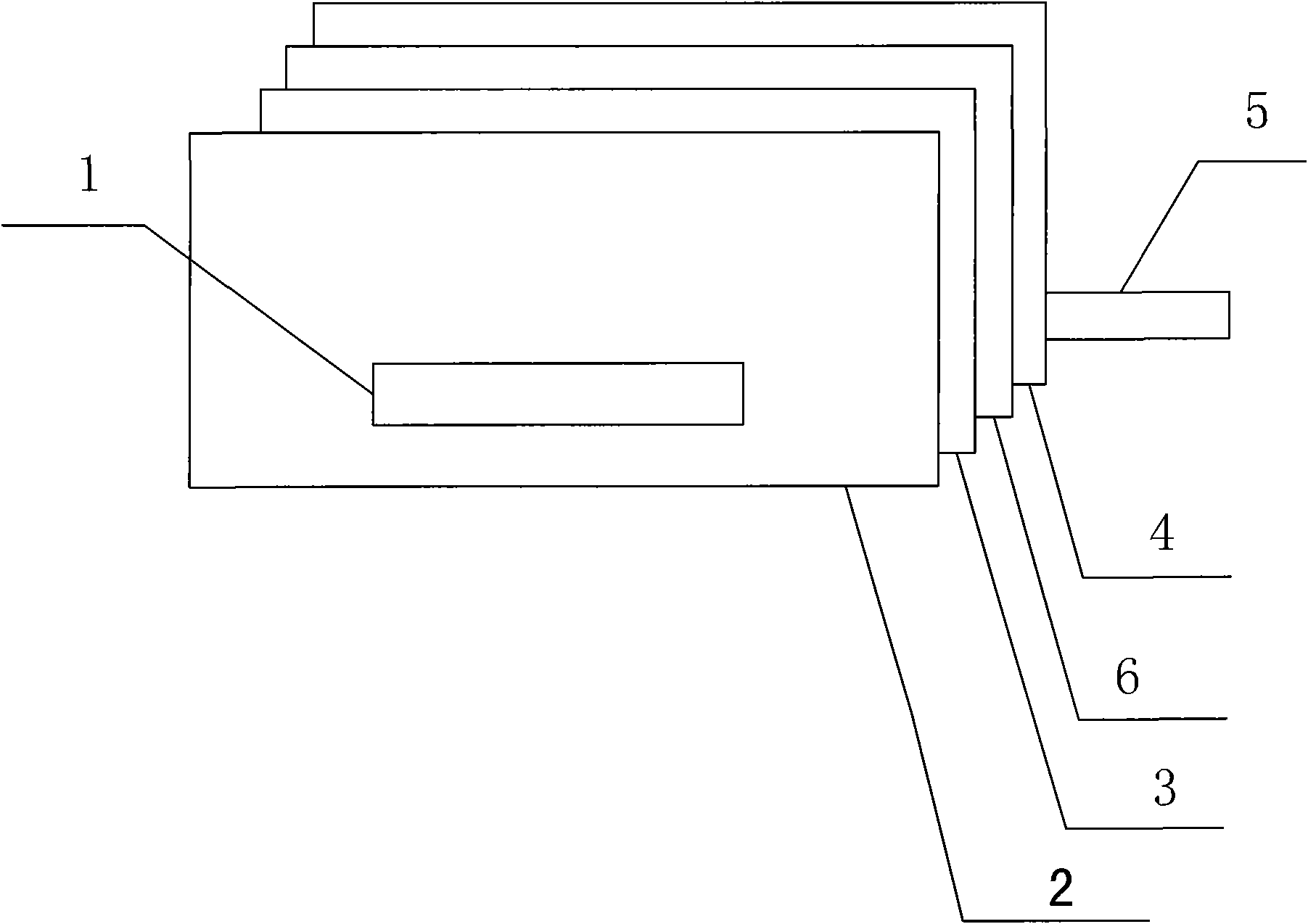

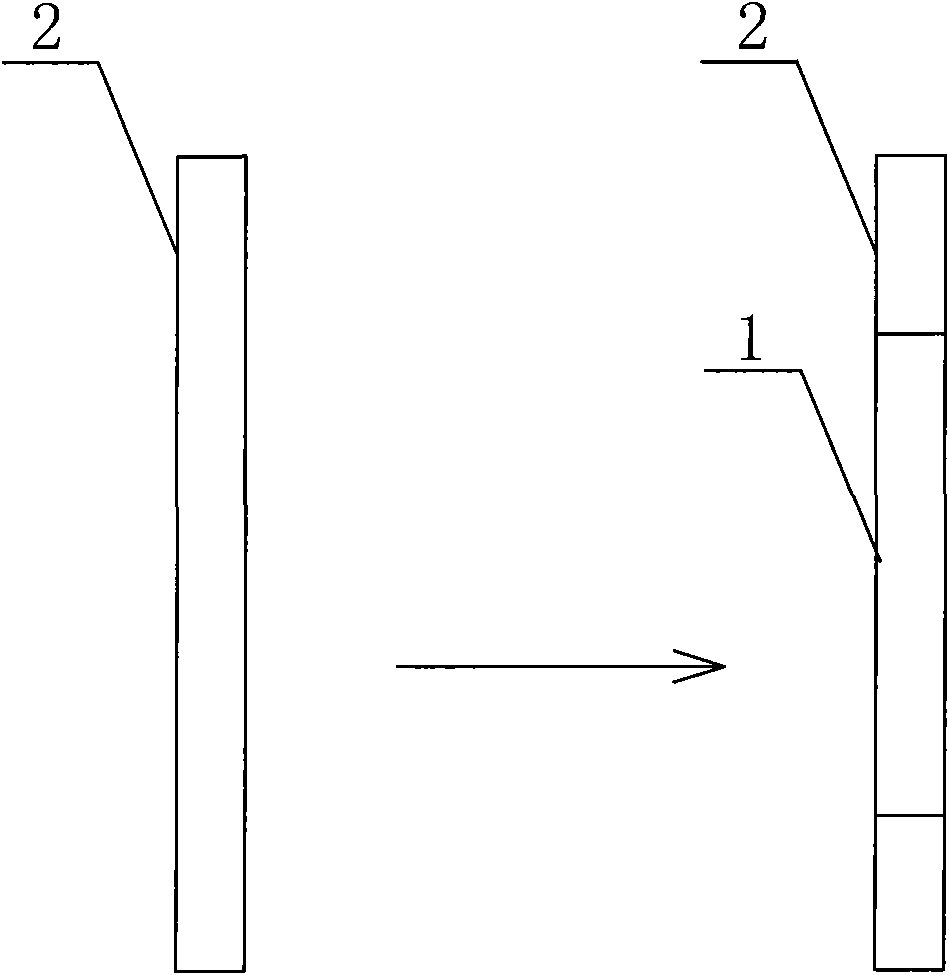

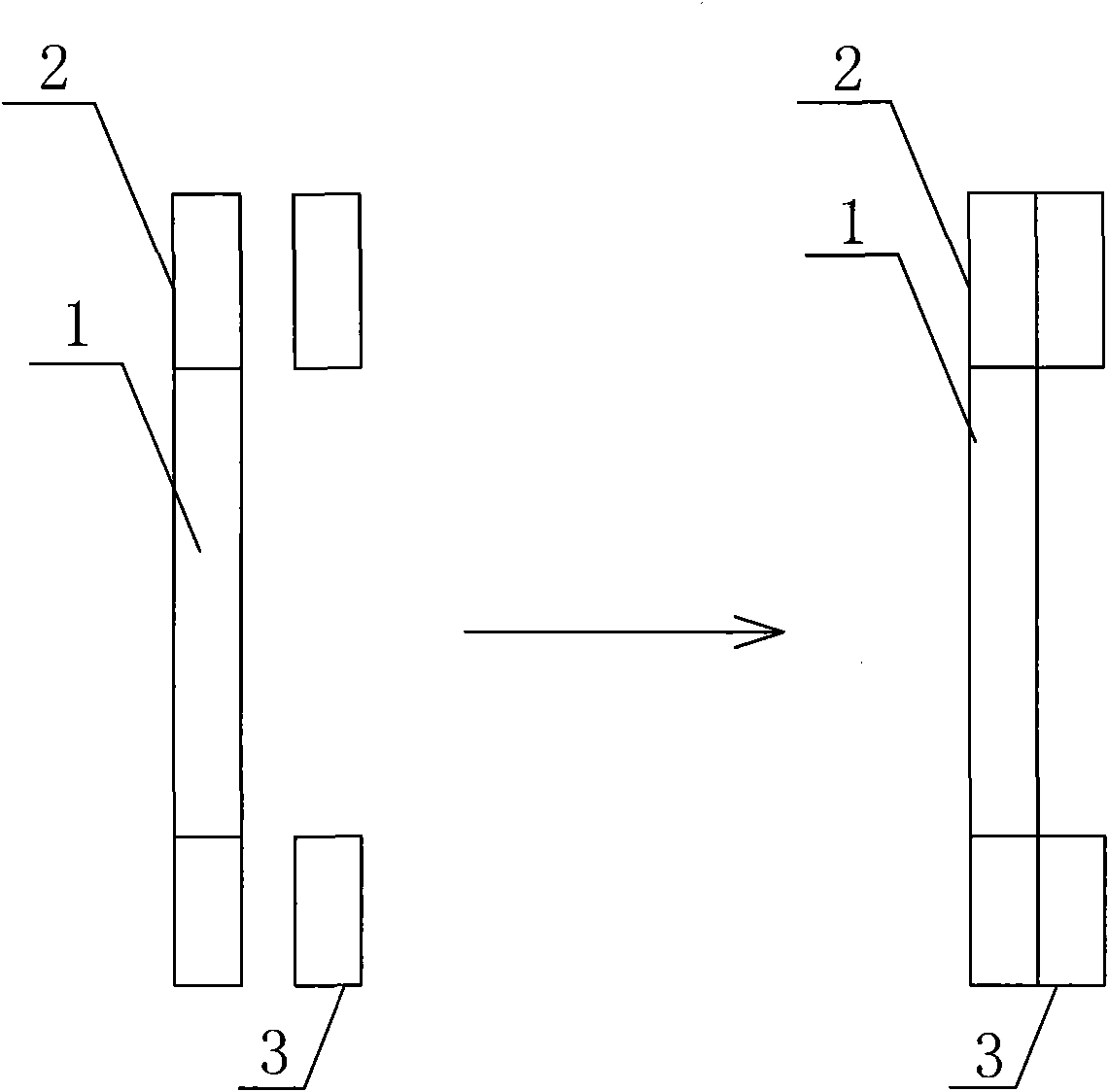

[0039] The invention discloses a color display transparent coating member, such as figure 1 , including a transparent substrate 2; the rear portion of the transparent substrate 2 includes a multilayer structure layer, and the multilayer structure layer includes in turn from the front to the back direction: an optical film layer 3, a color ink layer 6 and an opaque layer Bottom 4.

[0040] In order to display the information on the inside of the transparent substrate 2, a certain display window area 1 can also be reserved in the transparent substrate 2, the display window area 1 is a display part, and the rest is a non-display part; the optical film layer 3 The color ink layer 6 and the opaque bottom layer 4 are located at the rear of the non-display portion; the rear of the display window area 1 includes a translucent color ink layer 5 .

[0041] The transparent substrate 2 is made of polymethacrylate (PMMA) sheet.

[0042] The color ink layer 6 is a color ink layer.

[004...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com