Counterweight device for elevator

A technology of elevators and counterweights, which is applied to elevators in buildings, transportation and packaging, and lifting equipment in mines, etc. It can solve problems such as adjustability that cannot meet the requirements of high-speed elevators, and heavy irons detachment. The risk of falling off, the effect of enhanced stability and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

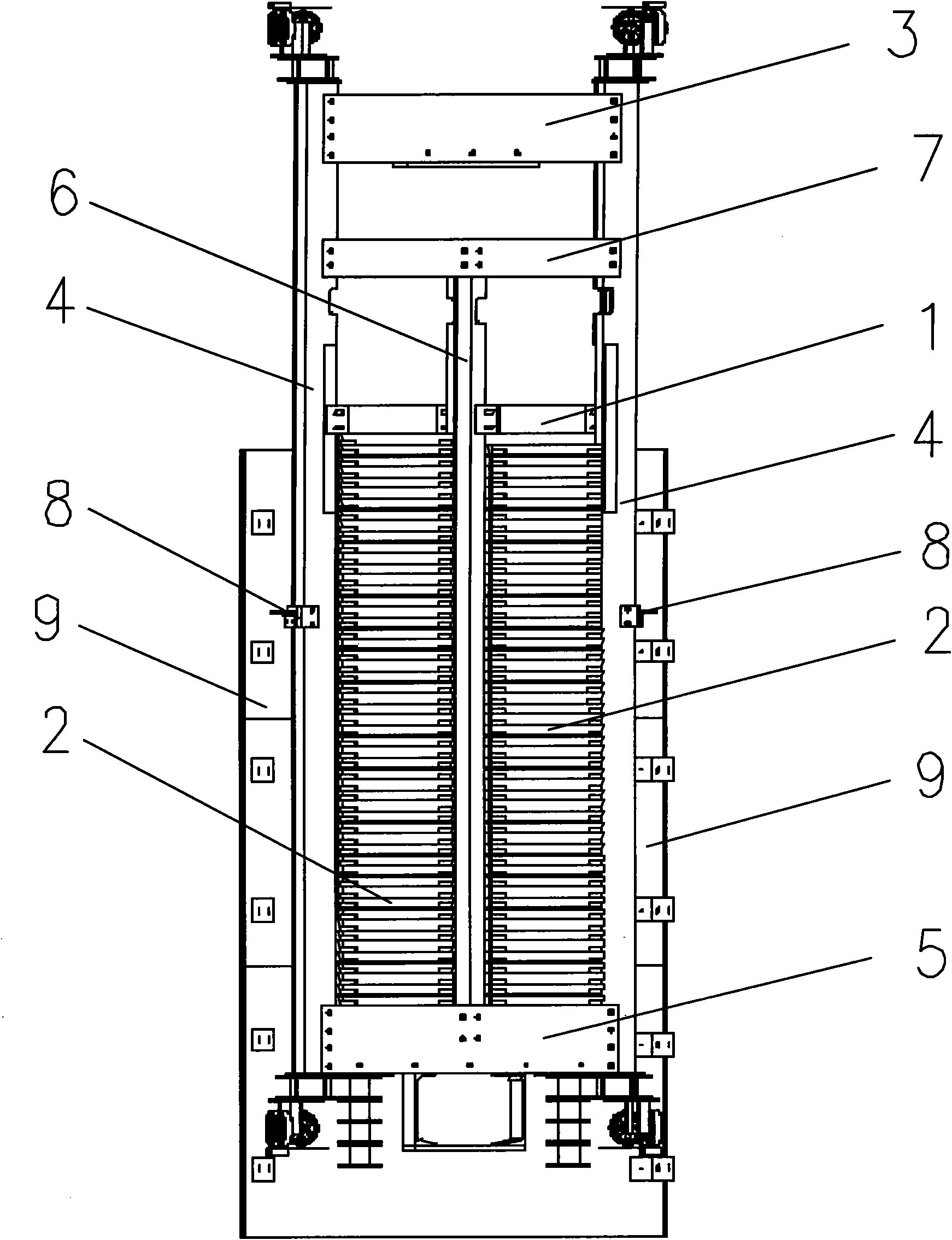

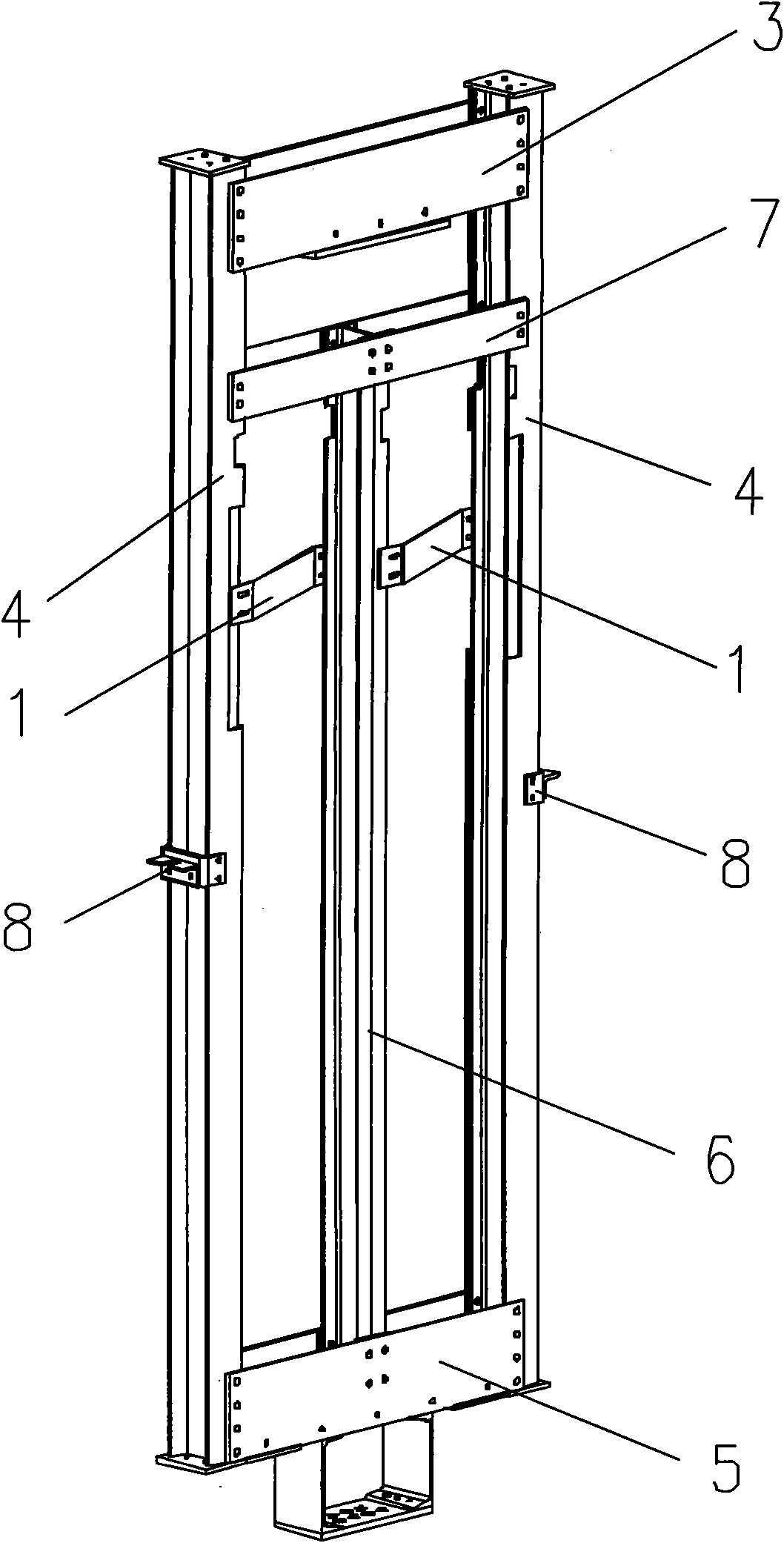

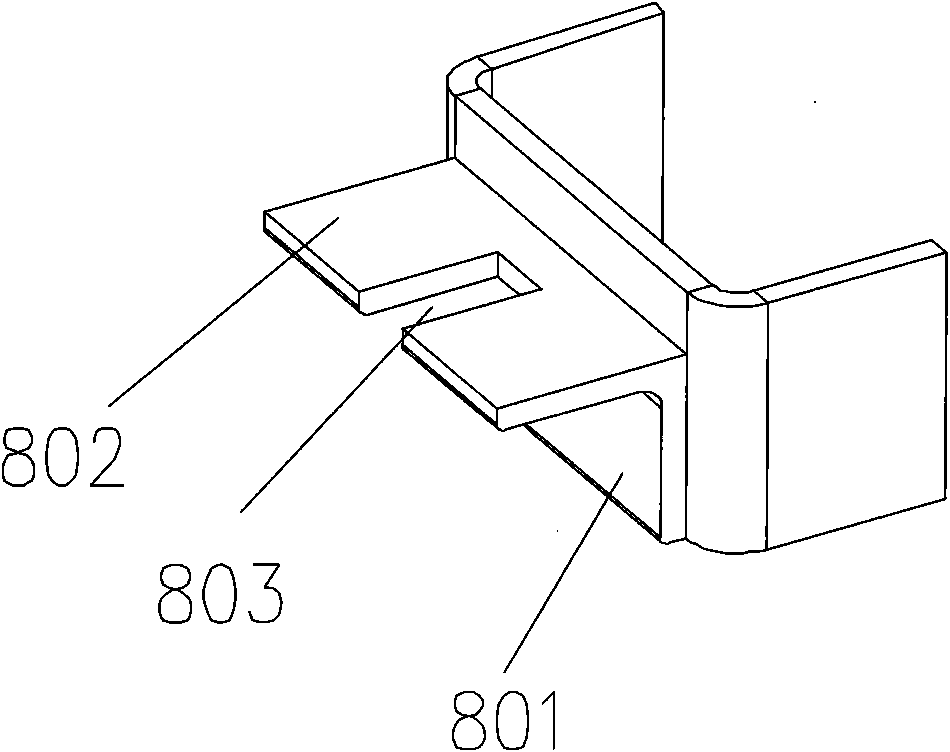

[0017] Such as figure 1 and figure 2 As shown, a counterweight device for an elevator of the present invention includes a counterweight frame, a counterweight iron pressing plate 1 , a counterweight iron 2 , a short vertical beam 6 and a transverse tie plate 7 . The counterweight frame includes two upper side beams 3, two vertical beams 4 and two lower side beams 5. Two vertical beams 4 are parallel to each other and placed vertically. The two upper side beams 3 are fixedly connected to the tops of the two vertical beams 4, and the two upper side beams 3 are parallel to each other. The two lower side beams 5 are fixedly connected to the lower ends of the two vertical beams 4, and the two lower side beams 5 are parallel to each other. The horizontal tension plate 7 is fixedly connected between the two vertical beams 4 . The short vertical beams 6 are located between the two vertical beams 4 and are parallel to the vertical beams 4 . The bottom ends of the short upright be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com