Paper cutting machine

A paper machine and frame technology, applied in the field of processing machinery, can solve the problems of low work efficiency, inevitable defective products, high labor costs, etc., and achieve the effects of improving work efficiency, reducing manpower into machines, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

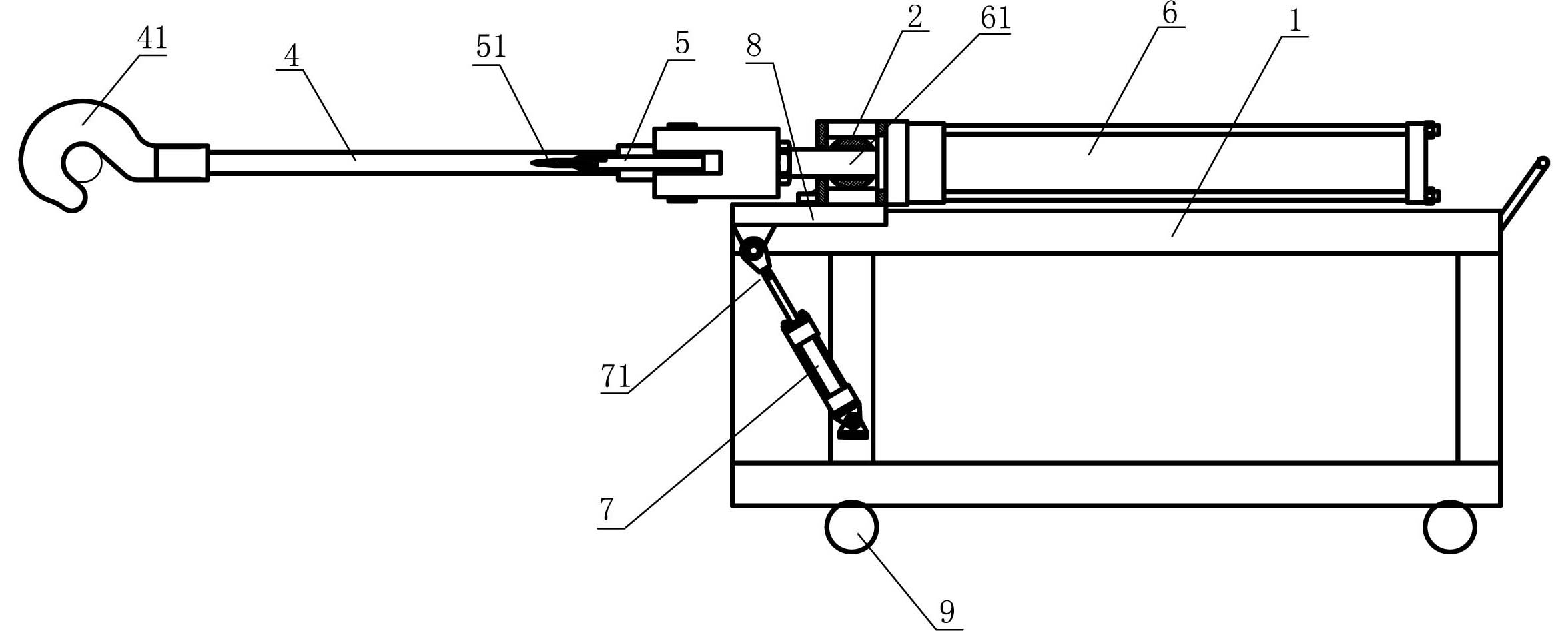

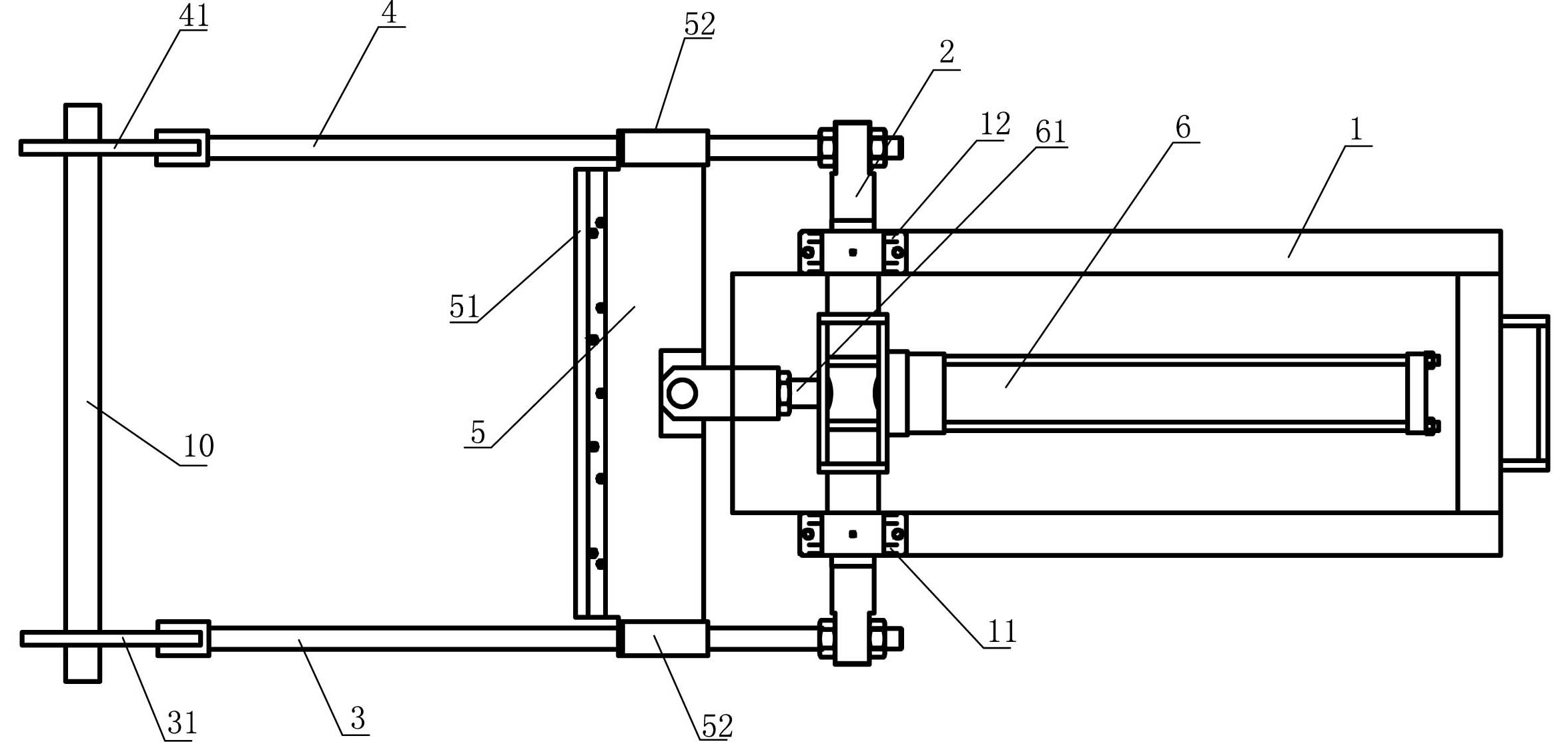

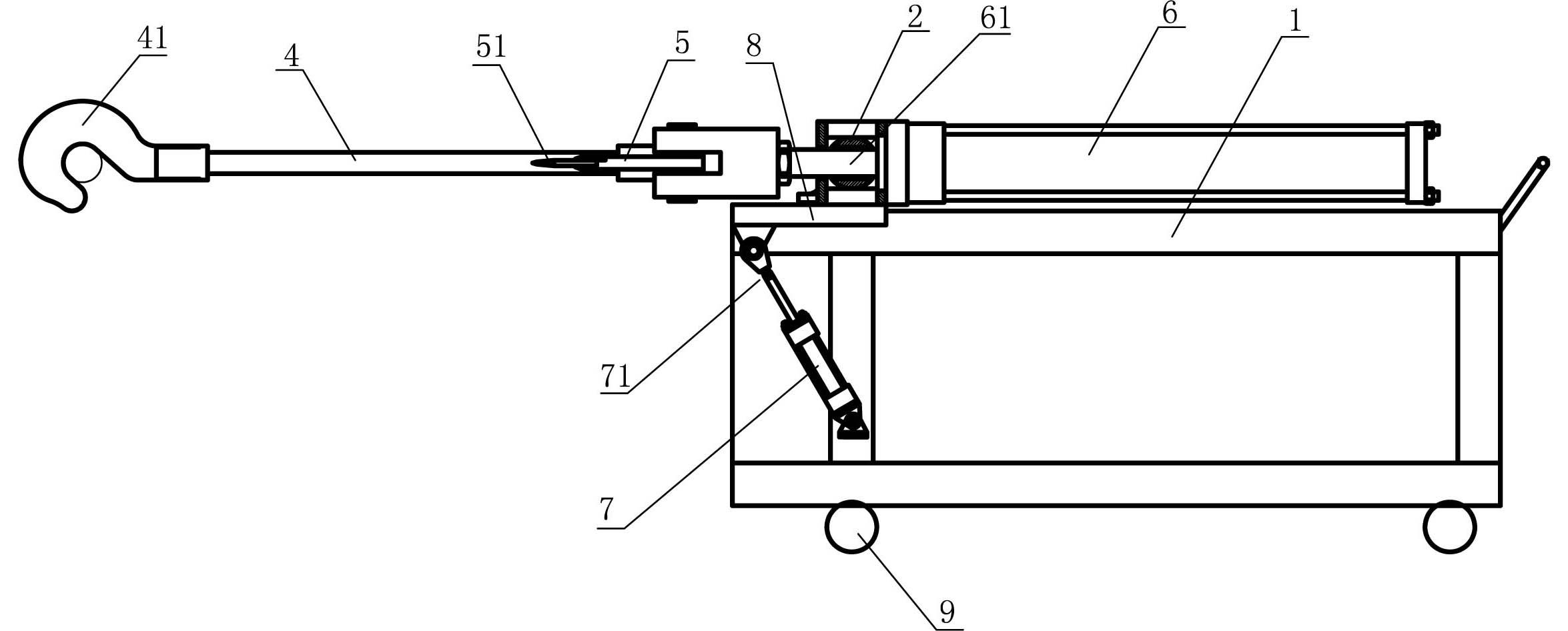

[0012] refer to figure 1 , figure 2 As shown, a paper splitter includes a frame 1, a main shaft 2, left and right tie rods 3, 4, a knife seat 5 and a cutter 51, and the main shaft 2 is laterally installed on the frame 1 through left and right bearing seats 11, 12. Up, the left and right pull rods 3,4 are fixed on the two ends of the main shaft 2, the left and right pull rods 3,4 protrude forward, and the front ends of the left and right pull rods 3,4 are provided with drag hooks or pull rings 31,41; the main shaft 2 A hydraulic cylinder 6 is fixed, and the telescopic arm 61 of the hydraulic cylinder 6 is connected to the knife seat 5. The knife seat 5 is equipped with a cutter 51. The two ends of the knife seat 5 are respectively provided with sliding sleeves 52, and the sliding sleeves 52 are respectively sleeved on the left and right pull rods. On 3,4; Frame 1 also installs the second hydraulic cylinder 7 that can make main shaft 2 take left and right bearing seat 11,12 as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com