Photovoltaic roof tile

A photovoltaic and roof tile technology, applied in the field of roof tiles, can solve the problems of low photoelectric conversion rate of photovoltaic tiles, short life of photovoltaic cells, and inability to block wind and rain, and achieve stable power supply, high photoelectric conversion efficiency, and high power utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

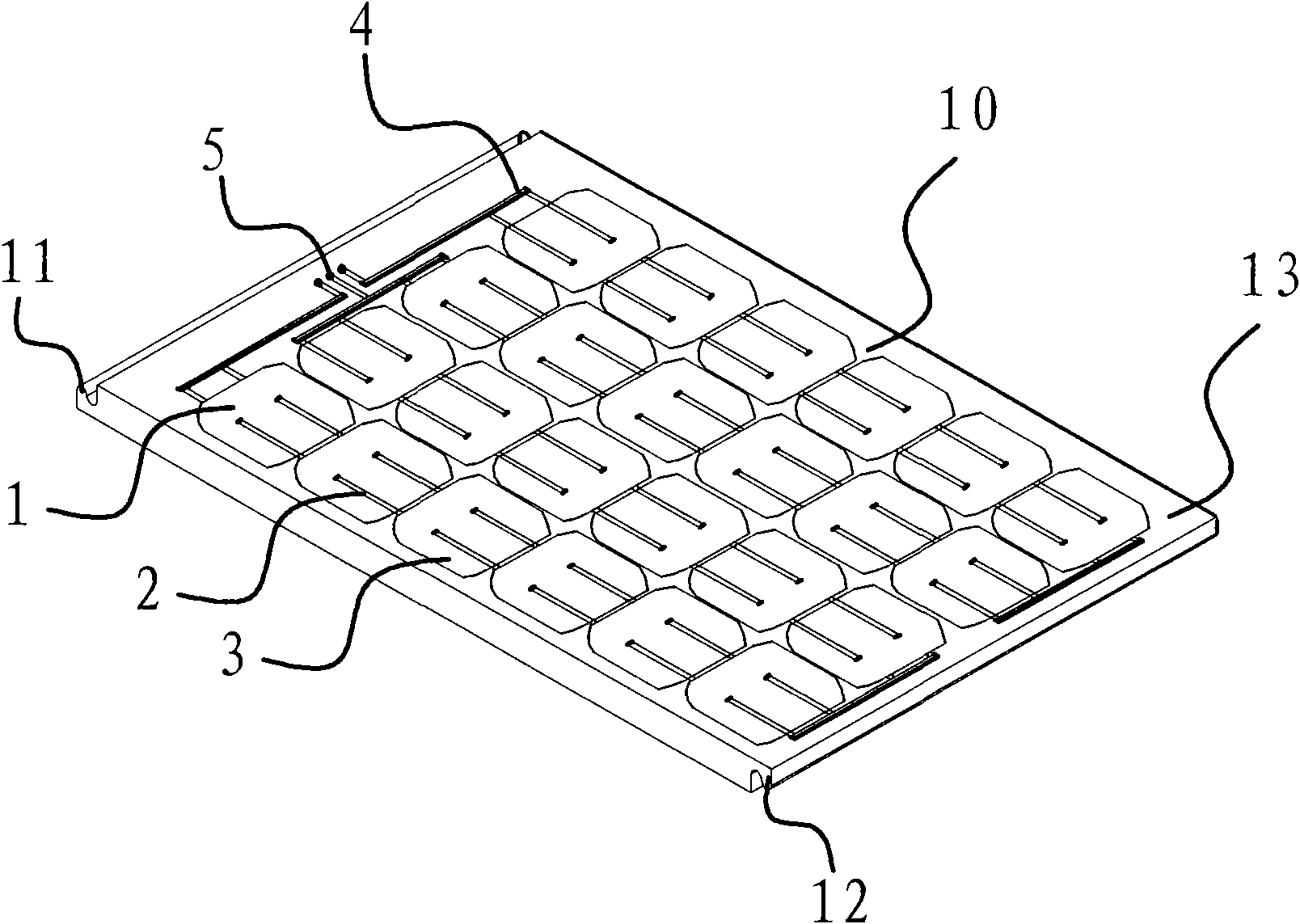

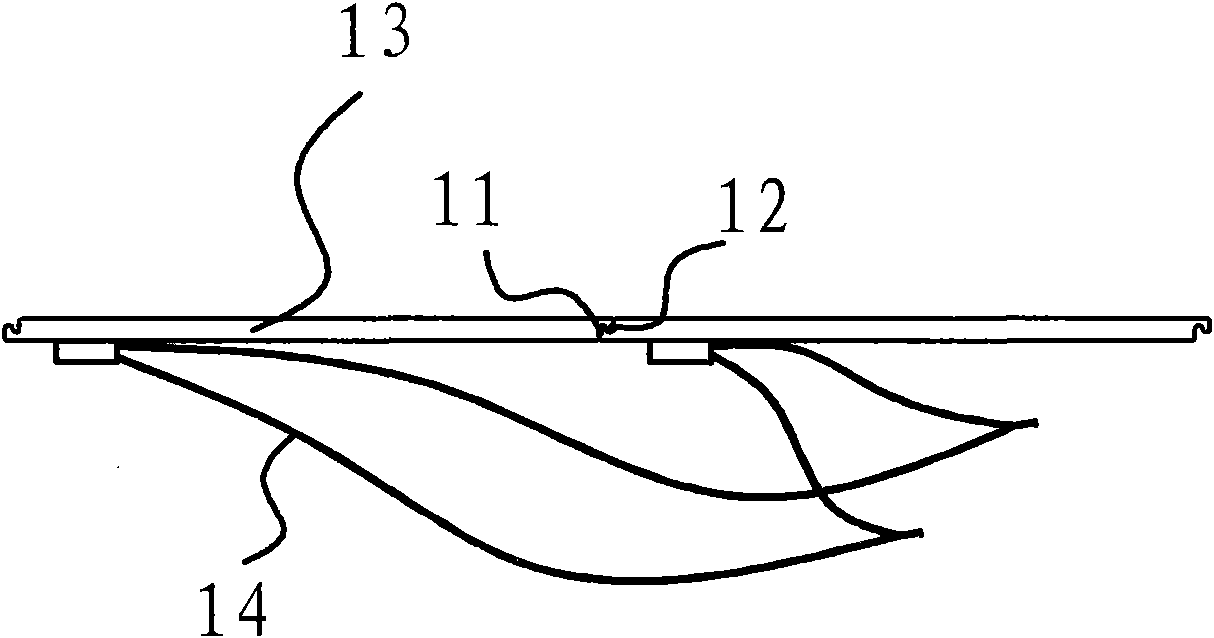

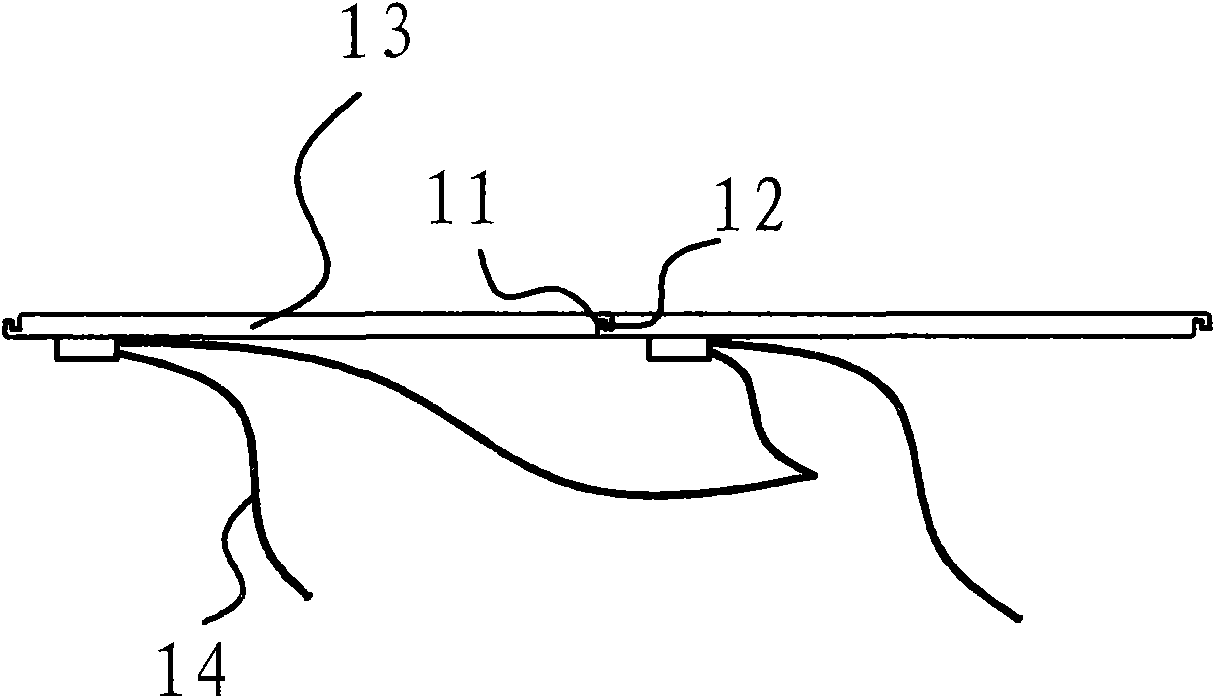

[0031] A photovoltaic roof tile, such as figure 1 , 2 As shown, including photovoltaic wafer 1, photovoltaic wafer 1 includes 24 silicon cells 3, interconnection bar 2 is welded between the positive pole of silicon cells 3 and the negative pole of adjacent silicon cells 3, the positive electrode of first silicon cells 3 A bus bar 4 is welded to the negative electrode of the tail block silicon cell 3; the photovoltaic chip 1 is provided with encapsulation material, the encapsulation material includes flat glass and a tile-type back material 13, and the flat glass is attached to the front of the photovoltaic chip 1 in a tile-type The front of the back material 13 is rectangular and is provided with a cavity, which is made of ceramics. The photovoltaic chip 1 and flat glass are packaged in the cavity of the tile-type back material 13, and one side edge of the tile-type back material 13 is provided with a The positive edge 11 that the front of tile-type back material protrudes, a...

Embodiment 2

[0036] The difference from the first embodiment is that the apexes of the protruding cross-sections of the front rib 11 and the back rib 12 are both square.

[0037] During installation, the positive pole of the power line 14 is connected to the negative pole of the adjacent photovoltaic roof tile power line 14 through the socket.

Embodiment 3

[0039] The difference from the first embodiment lies in that a locking edge 15 is provided on the protruding top ends of the front edge 11 and the back edge 12 .

[0040] During installation, the back edge 12 of the photovoltaic roof tile overlaps with the front edge 11 of the adjacent photovoltaic roof tile, and the locking edge 15 on the back edge 12 and the locking edge 15 on the front edge 11 of the adjacent photovoltaic roof tile are interlocked and locked .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com