Self-limiting electronic gear shifter

An electronic shifter, self-limiting technology, applied in the direction of components with teeth, belts/chains/gears, mechanical equipment, etc. Increase the front space and operating comfort, ensure safety, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

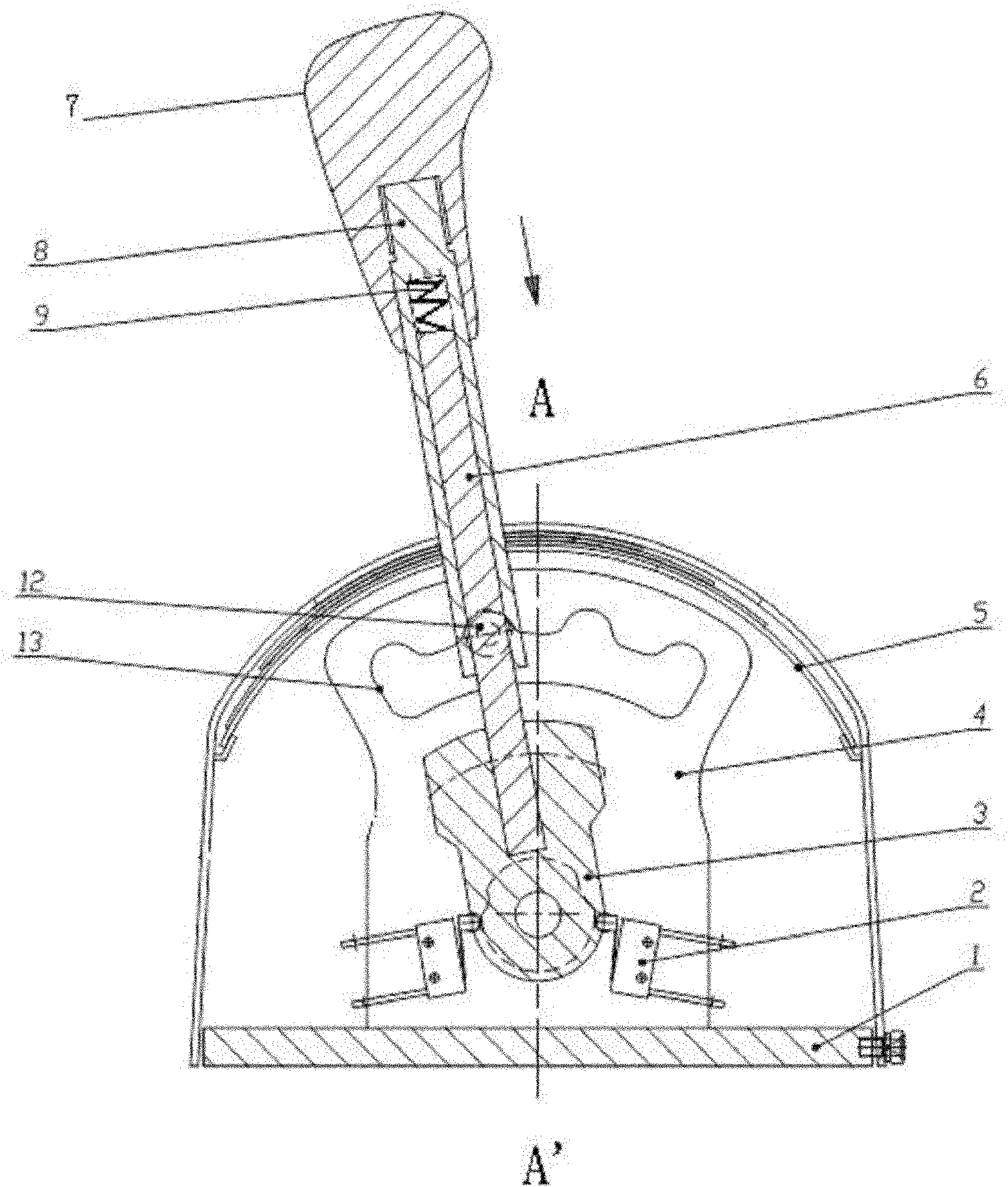

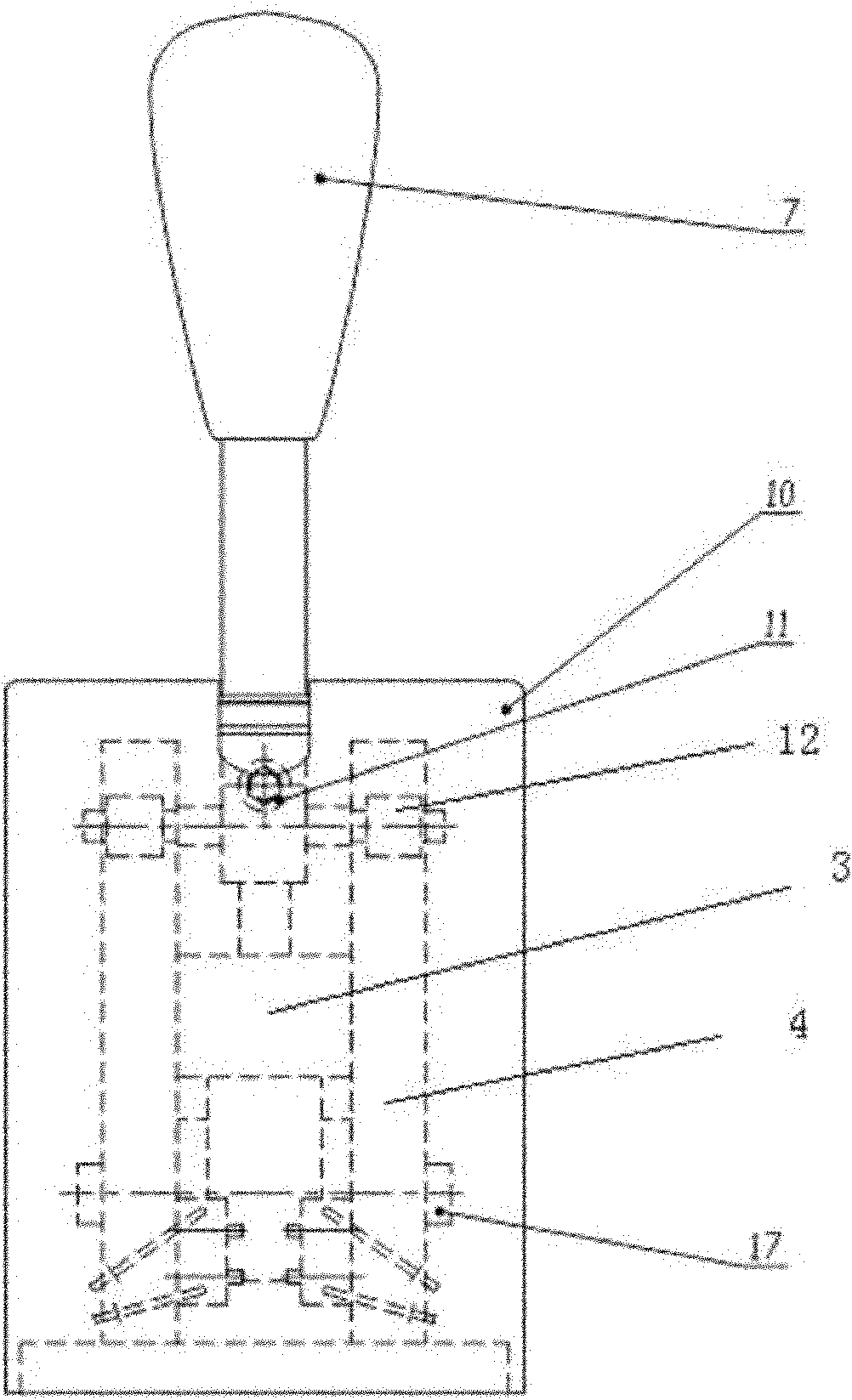

[0020] like figure 1 , 2 As shown, the self-limiting electronic shifter described in this embodiment mainly includes a base 1, a cover body 10, a shift lever 7, a cam seat 3 and a shift switch 2, and the cover body 10 is arranged on the base 1 A chamber is formed, the cam seat 3 and the shift switch 2 are arranged in the chamber, the shift switch 2 is in contact with the cam seat 3, the shift lever 7 is connected with the cam seat 3, and the cover body 10 is provided with a The chute that the rod 7 matches, the shift rod 7 is mainly composed of a depressible outer rod 8 and a connecting rod 6 arranged inside the outer rod 8, a spring 149 is arranged between the top of the connecting rod 6 and the outer rod 8, The other end is connected to the cam seat 3; an arc groove 13 is also provided in the chamber, and two limit seats 4 are arranged in the chamber, the cam seat 3 is connected between them by a rotating shaft 17, and the arc groove 13 is arranged on two limit seats. On t...

Embodiment 2

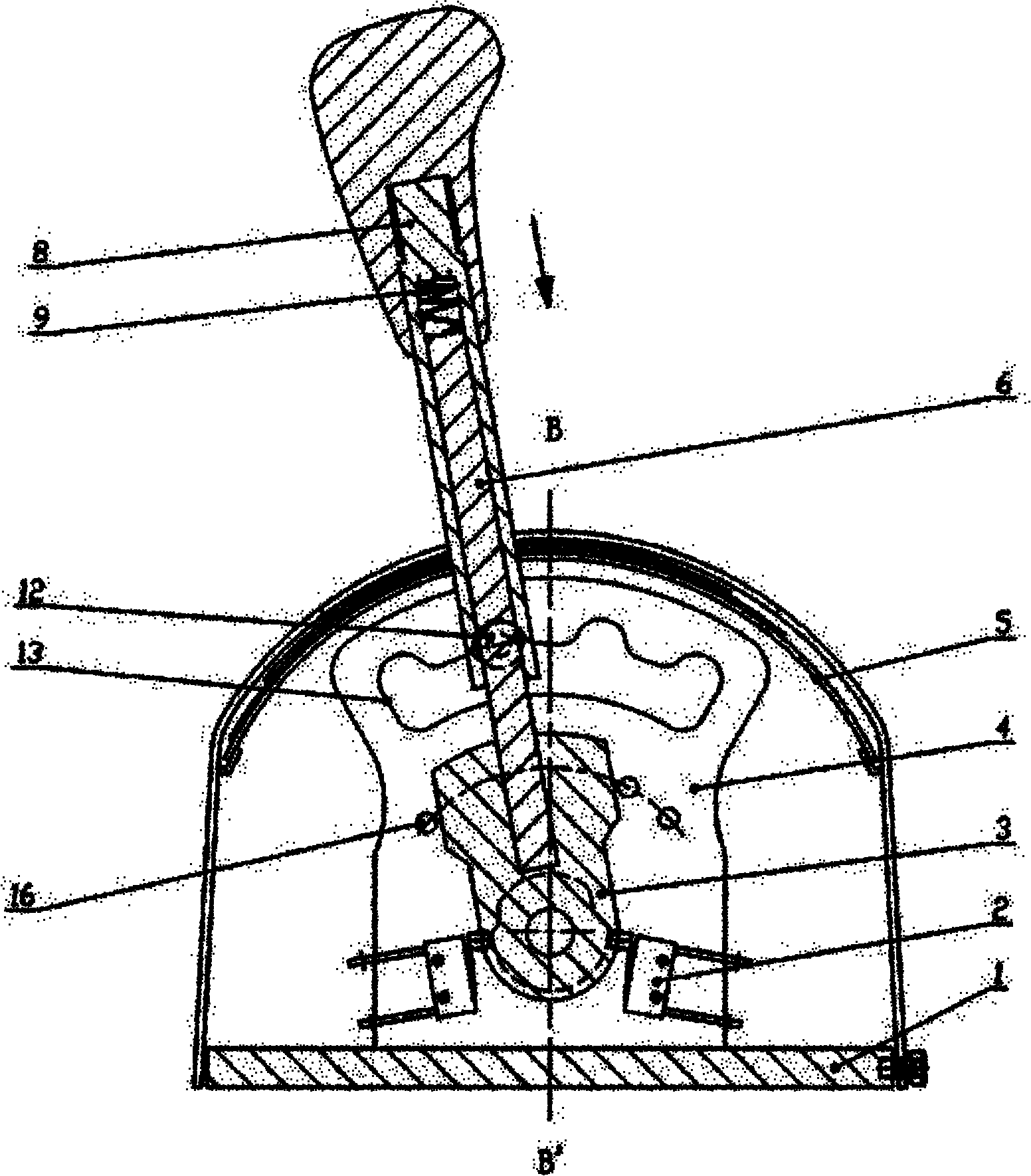

[0024] like image 3 , 4 As shown, in the self-limiting electronic shifter described in this embodiment, on the basis of Embodiment 1, a blind hole is provided on the cam seat 3, and a spring 149 and a ball are arranged in the blind hole, and the ball is a steel ball 15. The corresponding positions of each gear position on the limit seat 4 are provided with pits 16 that cooperate with the balls, so that the driver can obtain a good feel when shifting gears.

[0025] When in use, the wire plug drawn from the shift switch 2 is connected with the plug drawn from the gearbox to realize the gear shifting function of the gearbox. When there is no need to shift gears, the roller 12 on the shift lever 7 is located in one of the arc grooves 13 of the limit seat 4 , and the steel ball 15 is located in one of the pits 16 . When the shifter shifts gears, press the outer lever 8, the roller 12 on the outer lever 8 will withdraw from the arc groove 13 of the limit seat 4 to release the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com