Gas cooker igniter zero-second ignition realization circuit

A zero-second ignition and stove point technology, applied to heating fuel, household stove/stove, gaseous heating fuel, etc., can solve the problems of closed gas source, unsustainable fire, and gas stove that cannot be ignited immediately, so as to achieve maintenance The effect that ignites, improves convenience of the use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

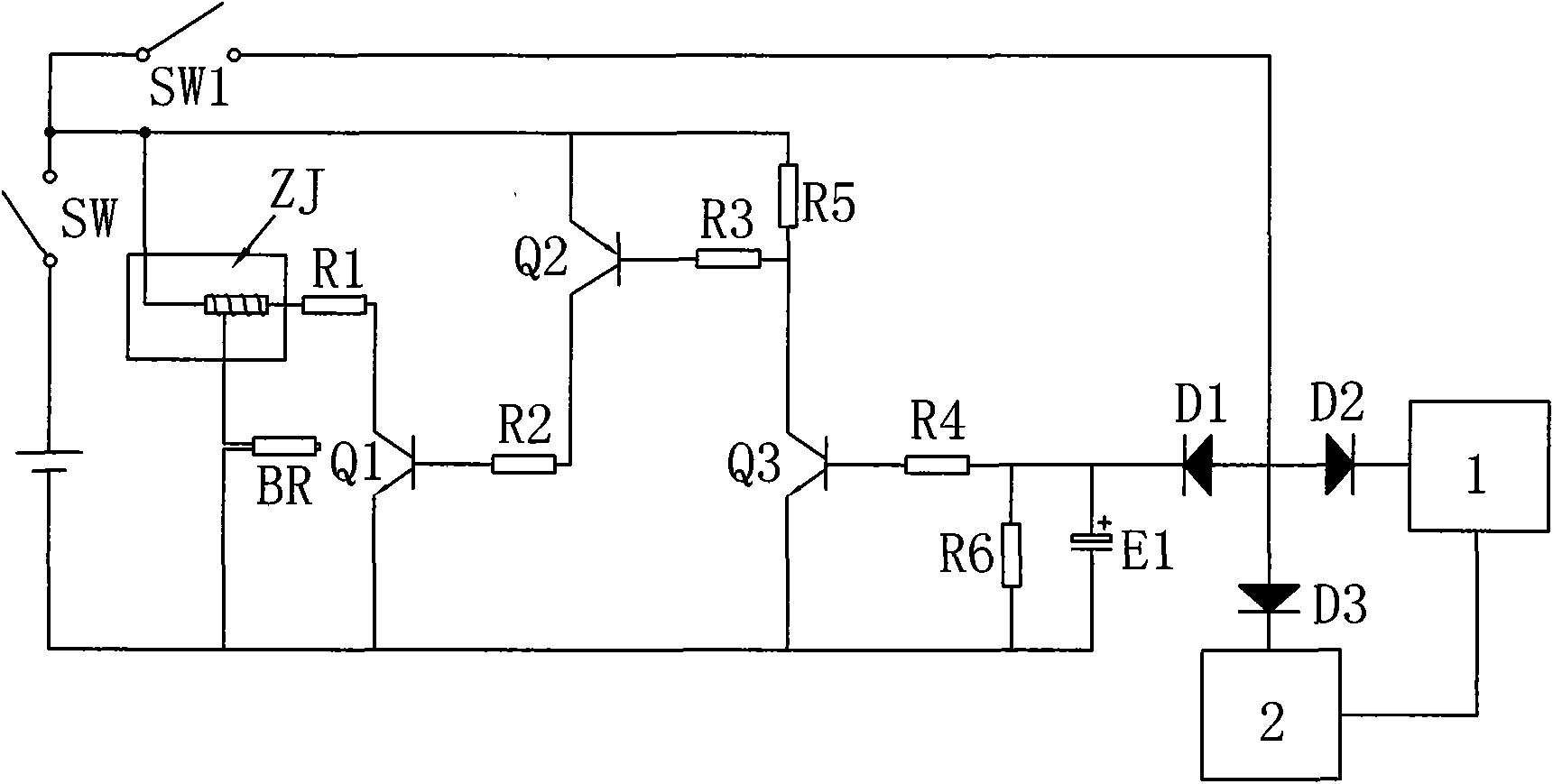

[0015] Embodiment: a zero-second ignition realization circuit of a gas stove igniter, including a power supply, a power switch SW, a self-priming valve ZJ, a thermocouple BR, a booster circuit 2 and a high-voltage package 1, the power switch SW and the power supply are connected in series, and the self-priming valve The middle of the coil of ZJ is connected to one end of the thermocouple BR, and also includes a micro switch SW1, a parallel sixth resistor R6 capacitor E1, the first, second, and third transistors D1, D2, D3 and the first, second, and three transistors Q1 , Q2, Q3, one end of the micro-switch SW1 is connected to one end of the series-connected power switch SW and the power supply, and the other end of the micro-switch SW1 is connected to the positive terminals of the first, second and third crystal diodes D1, D2, D3 at the same time, the said The negative terminal of the first transistor D1 is connected to the base of the third transistor Q3, and both ends of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com