Inverter controlling apparatus, and air conditioner and washer using the same

A control device, inverter technology, applied in the direction of output power conversion device, control system, general control strategy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

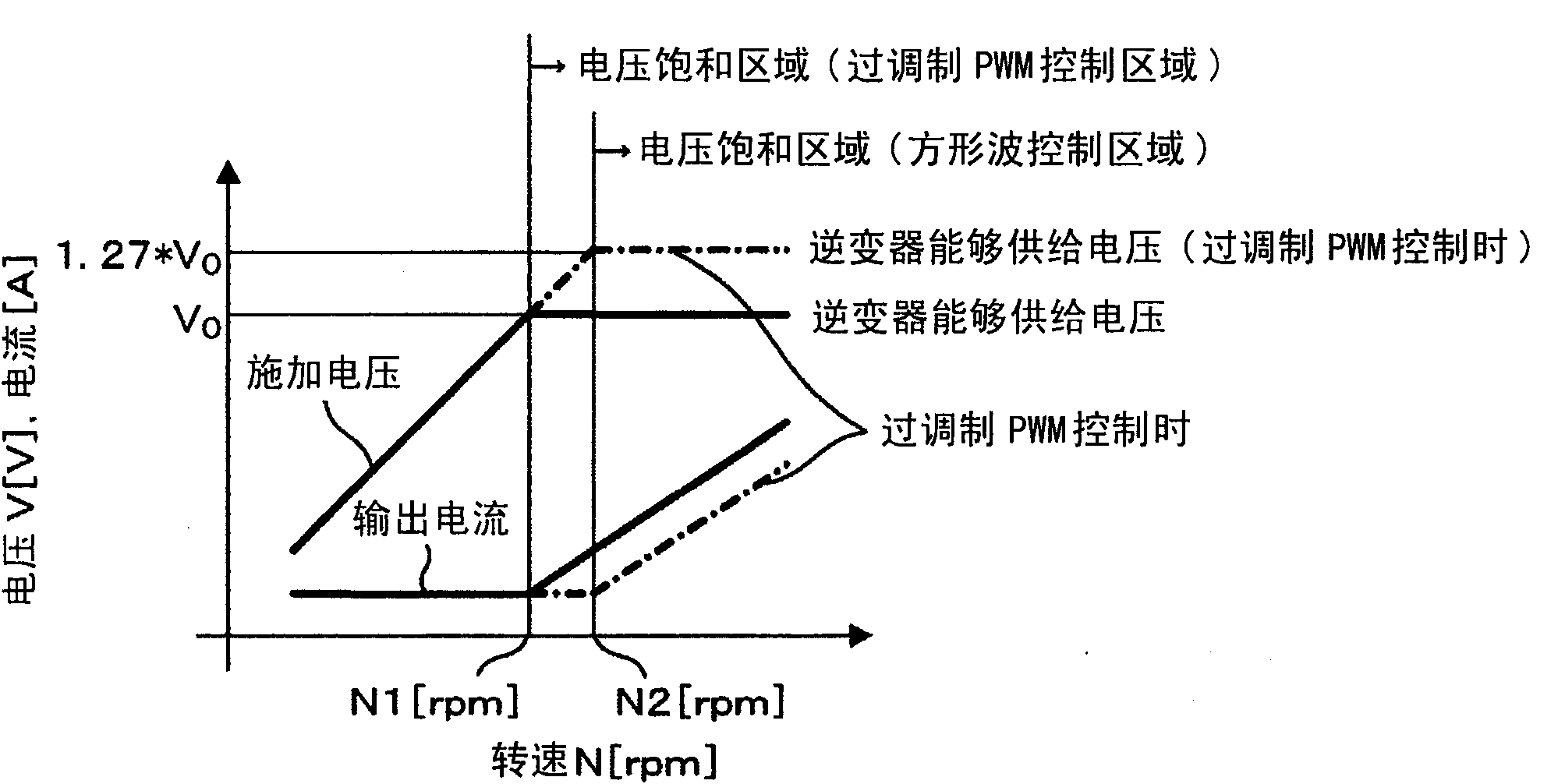

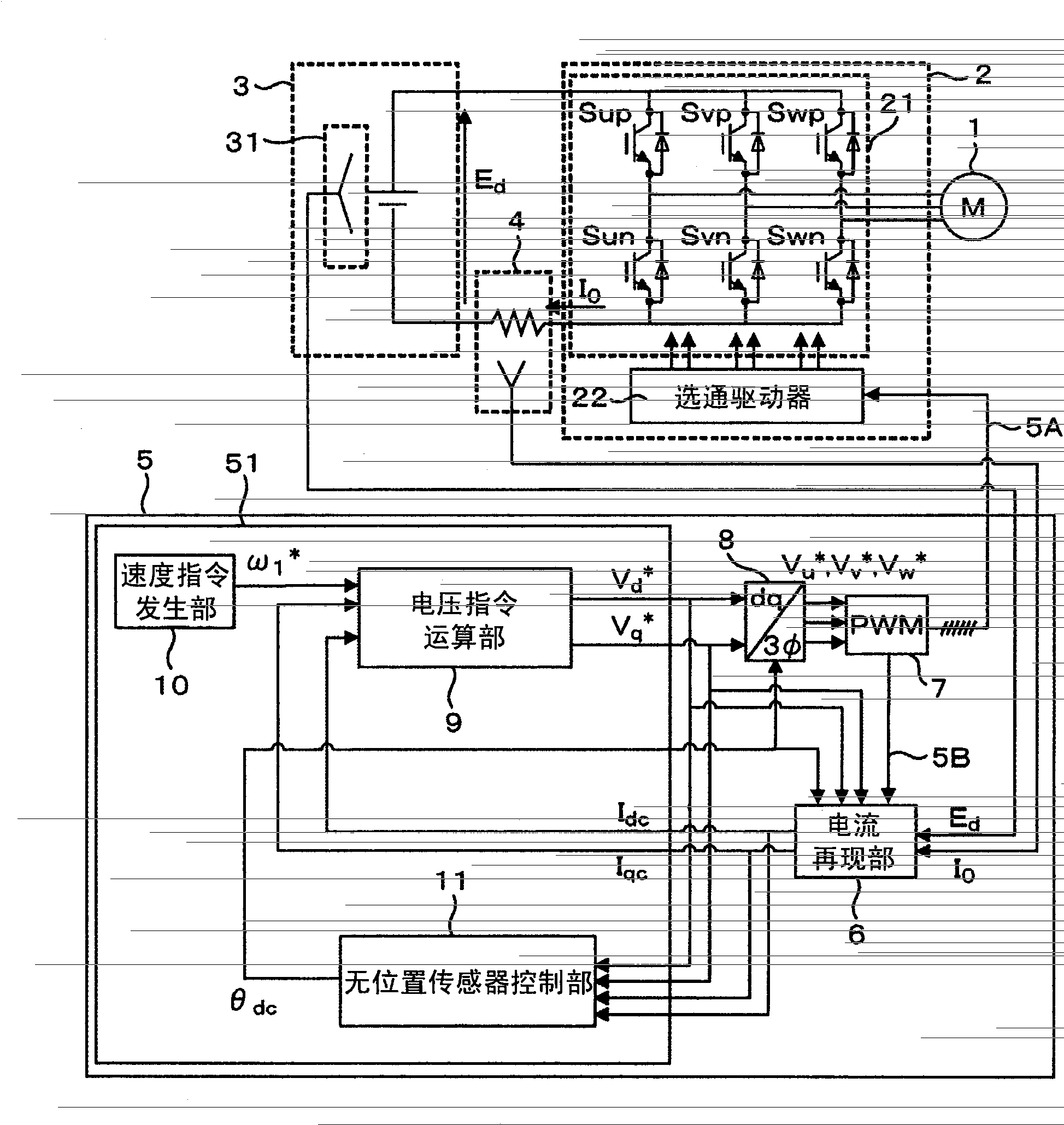

[0047] use Figure 3 ~ Figure 6 , the first embodiment of the present invention will be described.

[0048] image 3 shows the configuration of a motor drive device as an embodiment of the present invention, Figure 4 The processing of the current reproduction unit 6 is shown.

[0049] The inverter 2 includes: an inverter main circuit 21 composed of IGBTs and diodes, and a selection device for generating a gate signal applied to the IGBTs of the main circuit according to a pulse width modulation signal (PWM signal) 5A output from the control device 5. through the driver 22; according to the PWM signal 5A, the DC voltage E supplied from the DC power supply 3 d It is converted into a three-phase AC voltage and supplied to the motor 1 .

[0050] The DC bus current detector 4 uses a DC shunt resistor to detect the DC bus current I flowing into the inverter 2 0 , and output it to the control device 5.

[0051] The DC voltage detector 31 detects the DC voltage E applied to the...

Embodiment 2

[0143] use Figure 12 , Figure 13 , the second embodiment in which the motor drive device using the current detection method of the first embodiment is applied to the drive of the stirring blade of the washing machine will be described.

[0144] First, use Figure 12 , the overall configuration of the washing machine will be described.

[0145] The washing machine 200 is composed of an agitating blade 203 for agitating the washing tank, an agitating blade driving motor 202 for driving the agitating blade, a motor driver 201 for controlling the agitating blade driving motor 202, an inner washing tank 204 and an outer washing tank 205 for washing clothes.

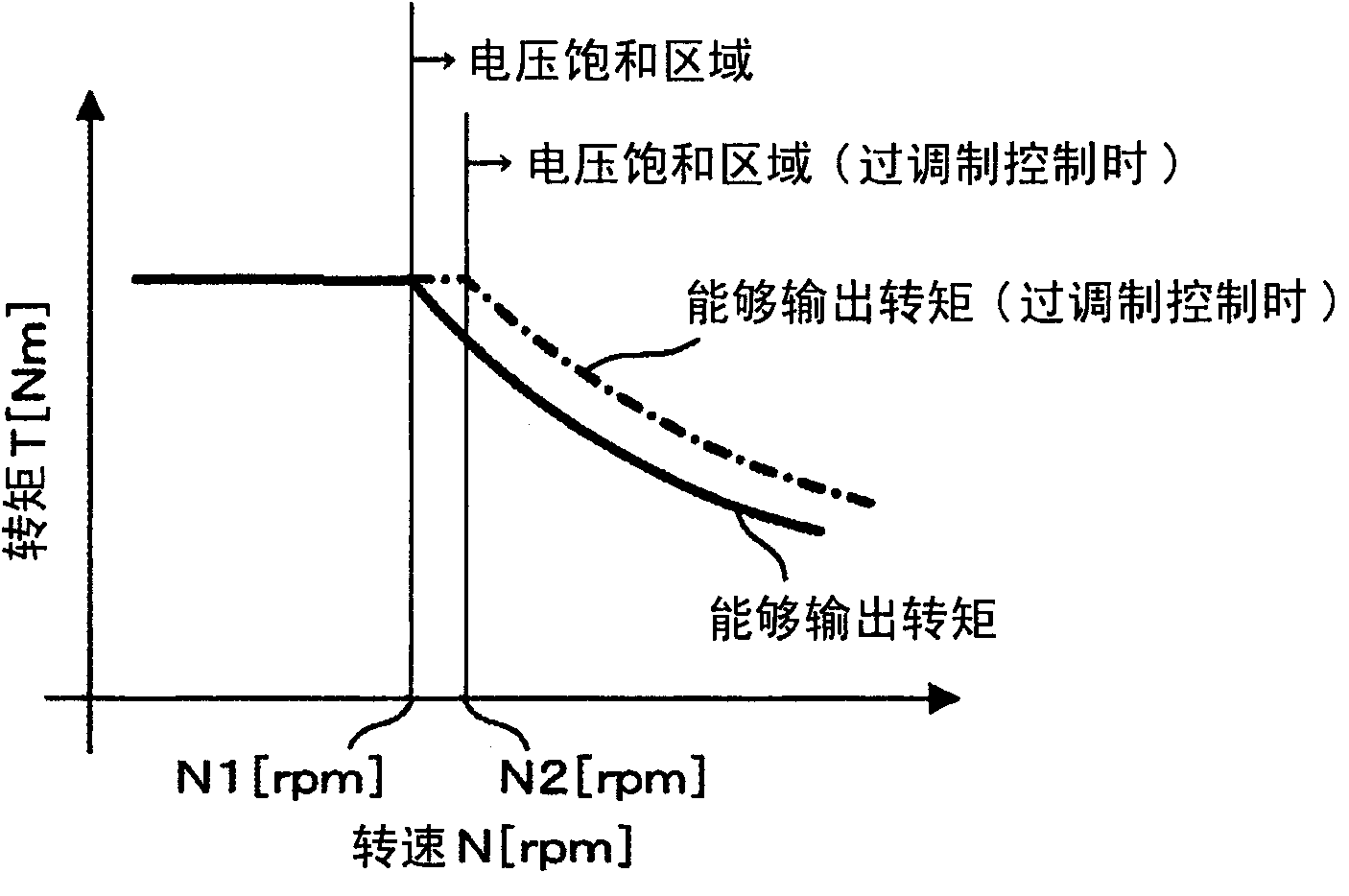

[0146] Here, using a schematic diagram showing the motor speed and torque characteristics showing the operating point of the stirring blade drive motor Figure 13 , the operating point of the stirring blade drive motor 202 will be described.

[0147] The stirring blade drive motor 202 operates at operating point A, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com