Reactive power compensation connection method of low-voltage side of high-capacity submerged-arc furnace

A connection method and submerged arc furnace technology, applied in the direction of reactive power compensation, reactive power adjustment/elimination/compensation, etc., can solve the problems affecting the compensation effect, achieve good compensation effect, improve smelting characteristics, and significantly increase production and reduce consumption indicators Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The patent will be further described below in combination with specific implementation methods.

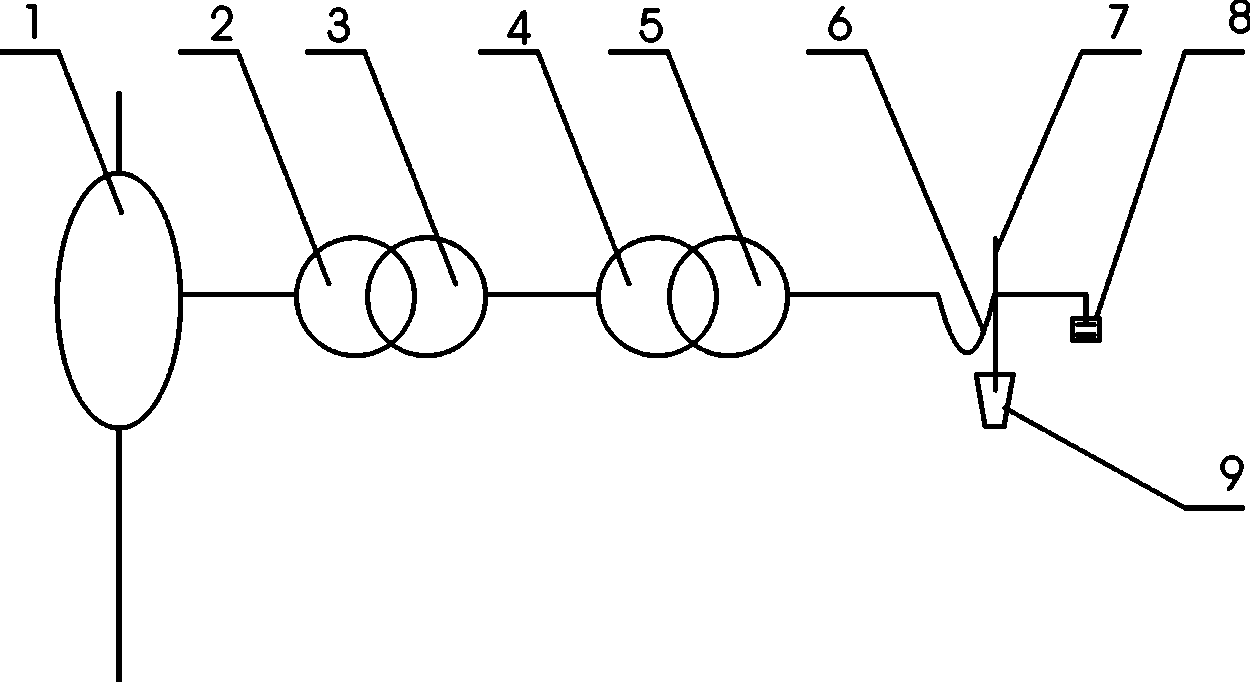

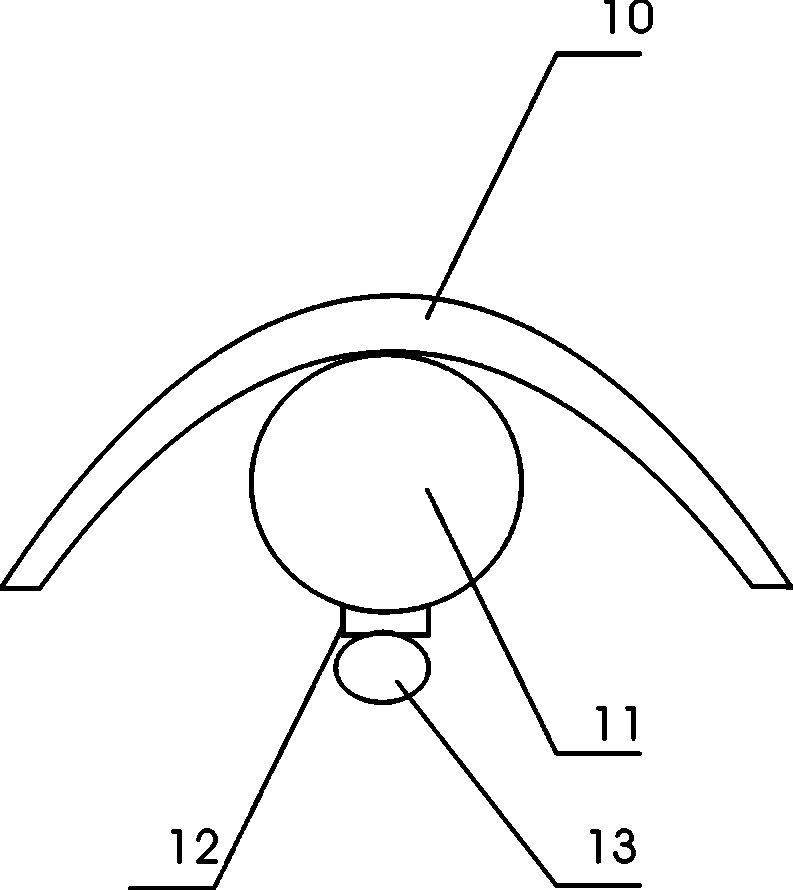

[0018] A connection method for reactive power compensation on the low-voltage side of a large-capacity submerged arc furnace. The capacitor device is installed on the electrode system, the short-network copper pipe is arranged between the electrode water-cooled cable and the copper tile, the copper bar is welded on the short-network copper pipe, and the electrode The water-cooled cable is connected to the copper bar, and the water-cooled cable is connected to the reactive power compensation equipment through the short-network copper pipe. The length of the water-cooled cable is the same as the length of the water-cooled cable connected to the short-network of the submerged arc furnace. The cross-sectional area of the water-cooled cable is 2000mm 2 , Copper tube outer diameter 60* inner diameter 40mm, wall thickness 10mm. Weld the copper bar with sufficient cross-sectional...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com