Steel grating welder of longitudinal flat steel delivery wagon with discharging car

A technology for unloading trucks and steel gratings, applied in welding equipment, welding equipment, arc welding equipment, etc., can solve the problems of low welding machine efficiency and manual operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

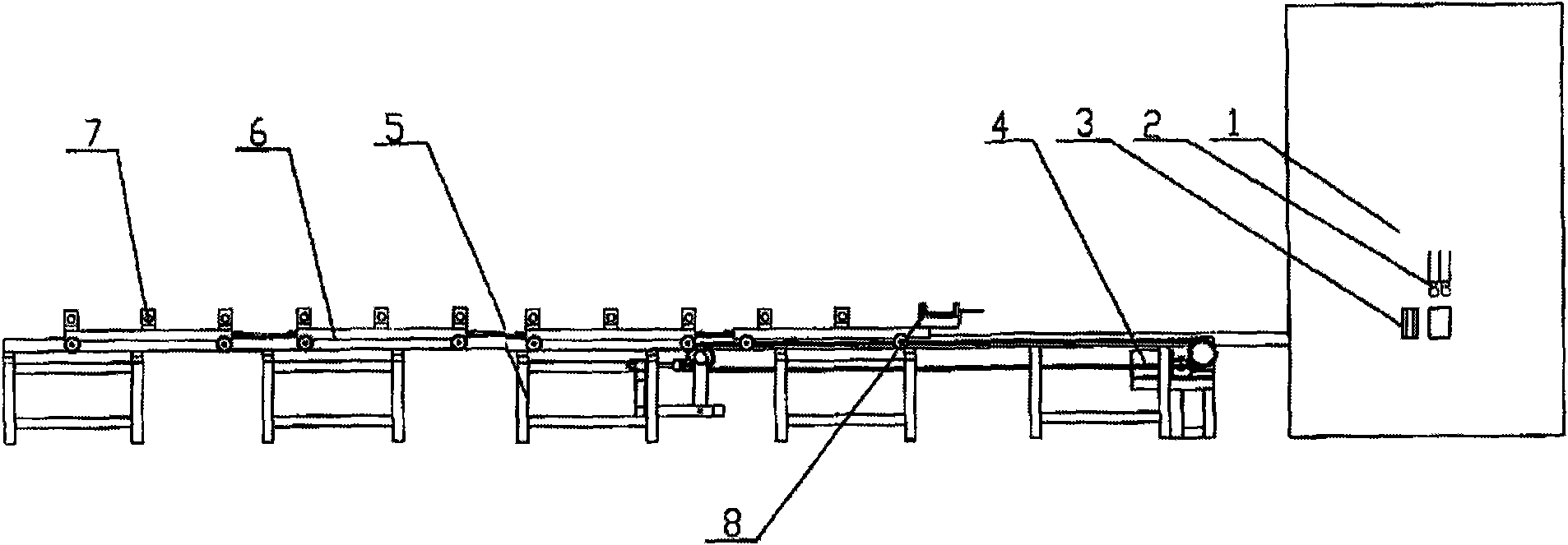

[0009] Control figure 1 , A steel grating welding machine with a longitudinal flat steel delivery car with unloading car, the steel grating welding machine 1 is provided with electrodes 2 and a support frame 3 in the machine, a longitudinal support 5 outside the welding machine, and a support 5 A trolley 6 is provided, a number of rollers 7 are provided on the trolley 6, a trolley support frame 8 is provided at the front end of the trolley 6, and a tractor 4 connected to the trolley 6 is provided on the bracket 5. Then the technical scheme of the present invention has been implemented.

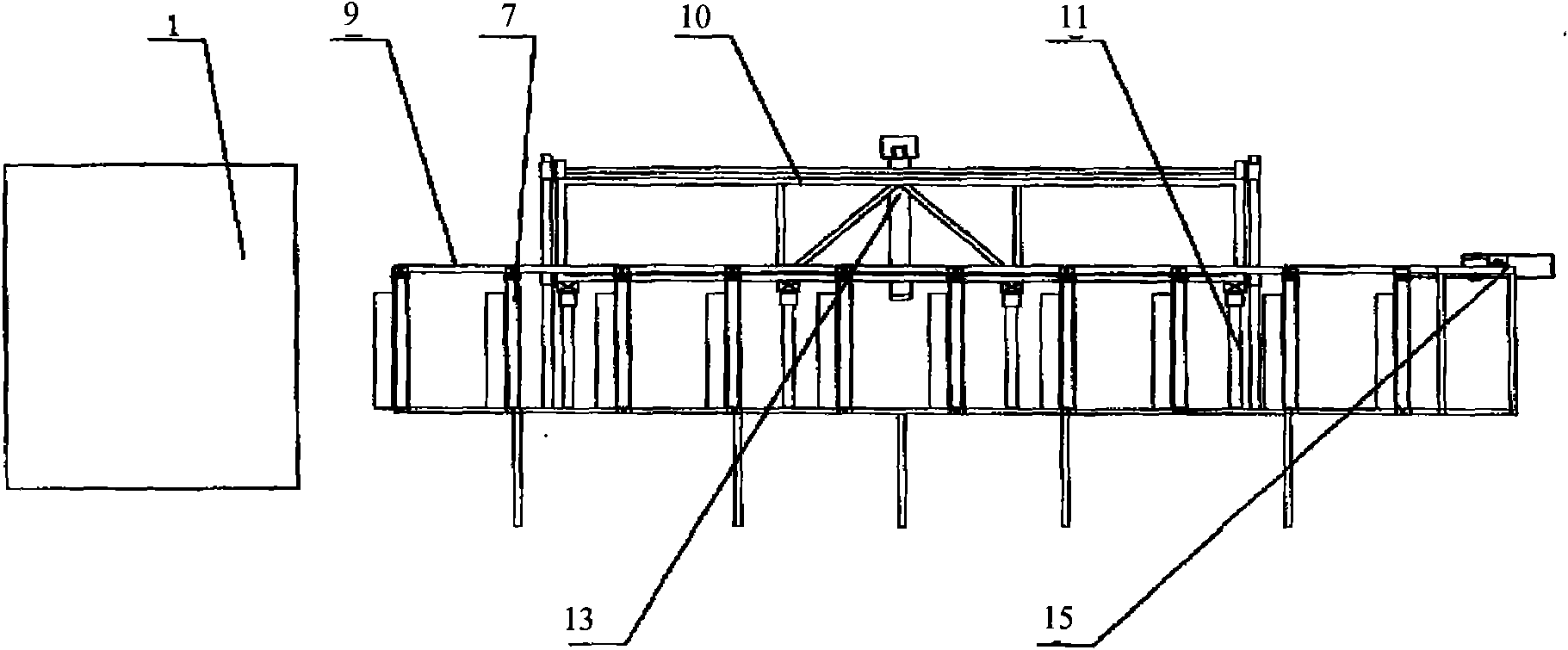

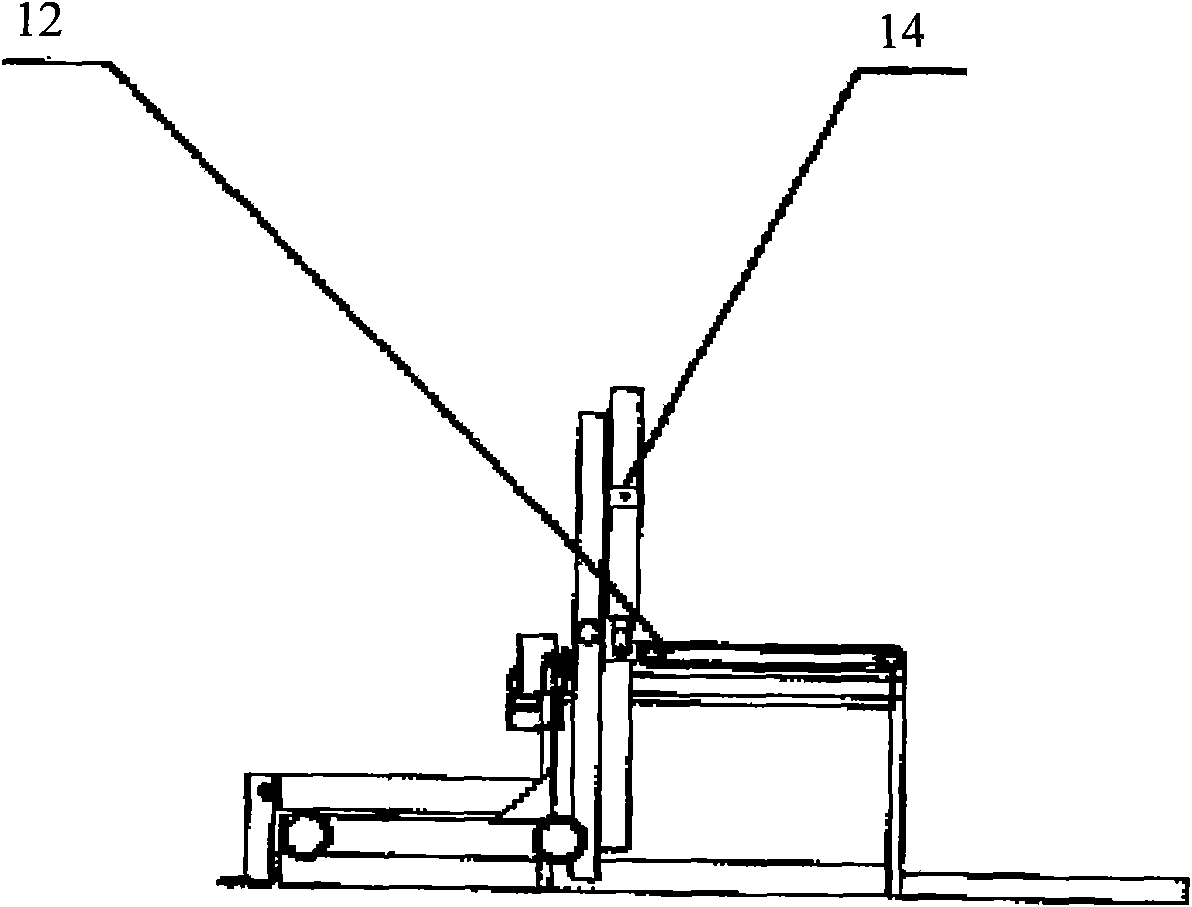

[0010] Control figure 2 , image 3 , A steel grating welding machine with a longitudinal flat steel delivery car with a discharge car. The discharge port of the welding machine 1 is connected to a support frame 9 with a number of rollers 7 and a roller drive 15, which is characterized in that the material is supported The middle of the frame 9 is provided with a wheeled unloading vehicle 10 tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com