Thick tube drop, thin tube drop casing type material drop crusher and material storage method

A sleeve-type, shredder-reducing technology, which is applied in the directions of transportation, packaging, loading/unloading, etc., can solve the problems of reducing the integrity of dicotyledonous plants such as peanuts, affecting the quality of raw materials, and restricting the development of enterprises, so as to reduce labor intensity and enter the warehouse The effect of high time and mechanization efficiency and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

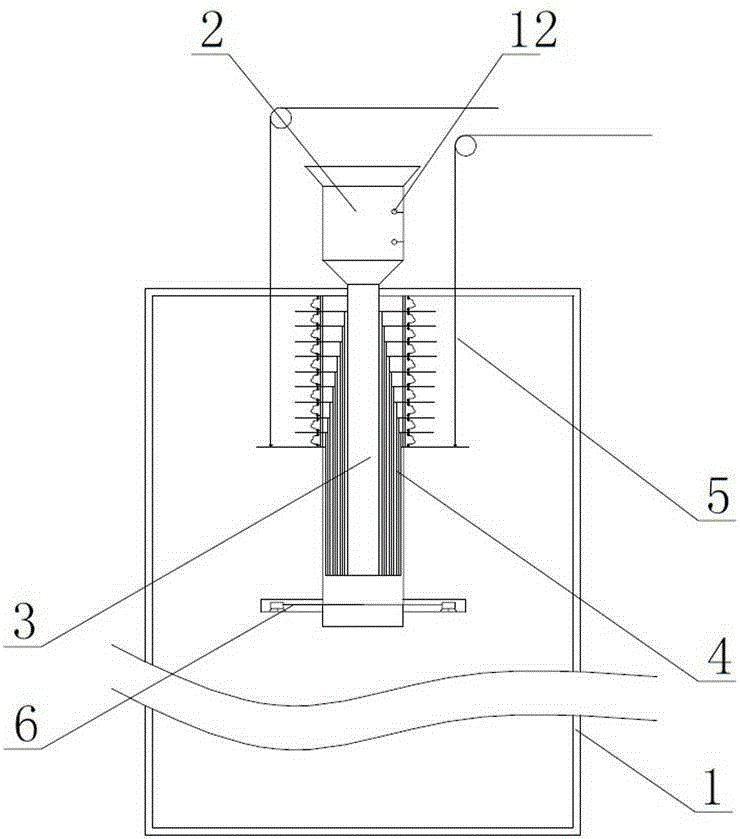

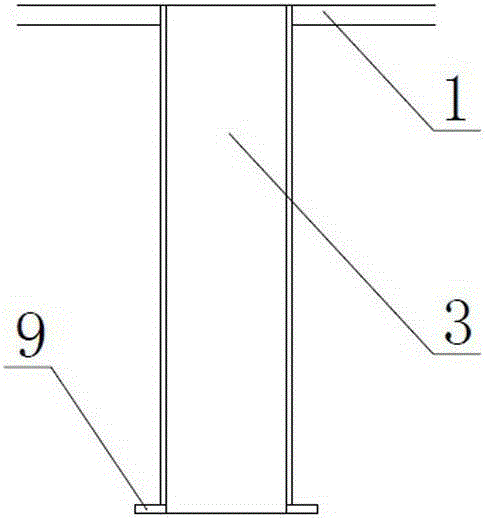

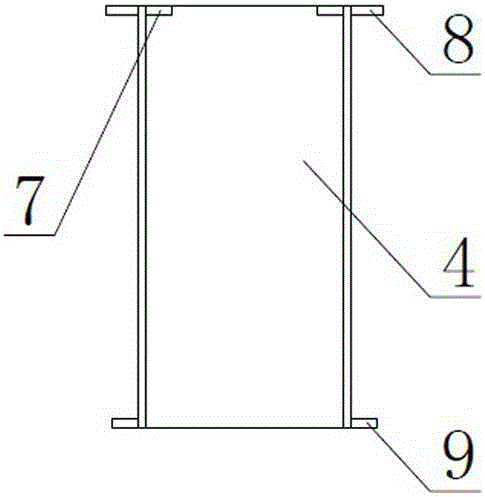

[0049] Embodiment one: see Figure 1 to Figure 6, a thick tube descending sleeve type material crushing device of the present invention, comprising a material guide inlet 2 and a material guide pipe 3 located at the top of the silo 1, the material guide inlet 2 is funnel-shaped, and the outside of the material guide inlet 2 A material level detector 12 is provided, and the outer side of the material guide pipe 3 is sequentially socketed and socketed with 4 movable casings 4 according to the height of the silo, and the innermost movable casing 4 and the top of the silo are adjacent to each other. A tension support mechanism is provided between the movable sleeves 4, and the tension support mechanism includes an outer tension flange 9 arranged at the outer bottom of the material guide tube 3, an inner tension flange 9 arranged at the inner top of the movable sleeve 4 The tight flange 7, and the outer tension flange 9 arranged at the outer bottom of the movable sleeve 4, the oute...

Embodiment 2

[0050] Embodiment two: figure 1 , Figure 7 ~ Figure 11 , the structure of the present invention is basically the same as that of Embodiment 1, and the similarities will not be repeated. The tensioning rope 10 provided between the movable sleeves 4, the length of the tensioning rope 10 is the displacement length of the corresponding movable sleeve falling, and the overlapping flange 8 of the overlapping support mechanism is provided with a limit block 11 , so that the storage space is reserved for the tension rope 10 when the movable sleeve shrinks.

Embodiment 3

[0051] Embodiment three: see Figure 12 to Figure 17 , a thin-tube descending casing type material crushing device of the present invention, comprising a material guide inlet 2 and a material guide pipe 3 located at the top of the silo 1, the material guide inlet 2 is funnel-shaped, and the outer side of the material guide inlet 2 A material level detector 12 is provided, and the inner side of the material guide pipe 3 is sequentially socketed and socketed with movable sleeves 4, between the outermost movable sleeve 4 and the roof of the warehouse, and between two adjacent movable sleeves 4 All are equipped with a tension support mechanism, and the tension support mechanism includes an inner tension flange 7 arranged at the inner bottom of the material guide pipe 3, an outer tension flange 9 arranged at the top outside of the movable sleeve 4, And the inner tensioning flange 7 that is arranged on the bottom end of the inner side of the movable sleeve 4, the outer tensioning fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com