Machining equipment

A technology of processing equipment and equipment, which is applied in the field of processing equipment and mechanical processing equipment, can solve the problems of high defective rate, instability, and low efficiency, and achieve the effects of high processing efficiency, high processing molding efficiency, and high mechanization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

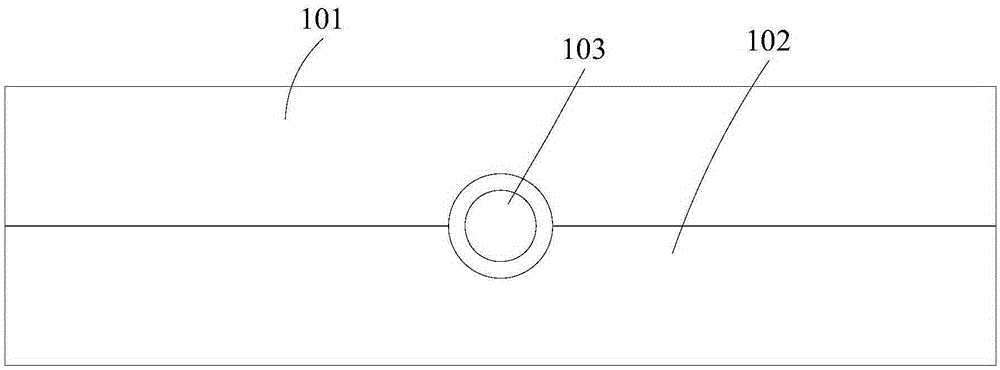

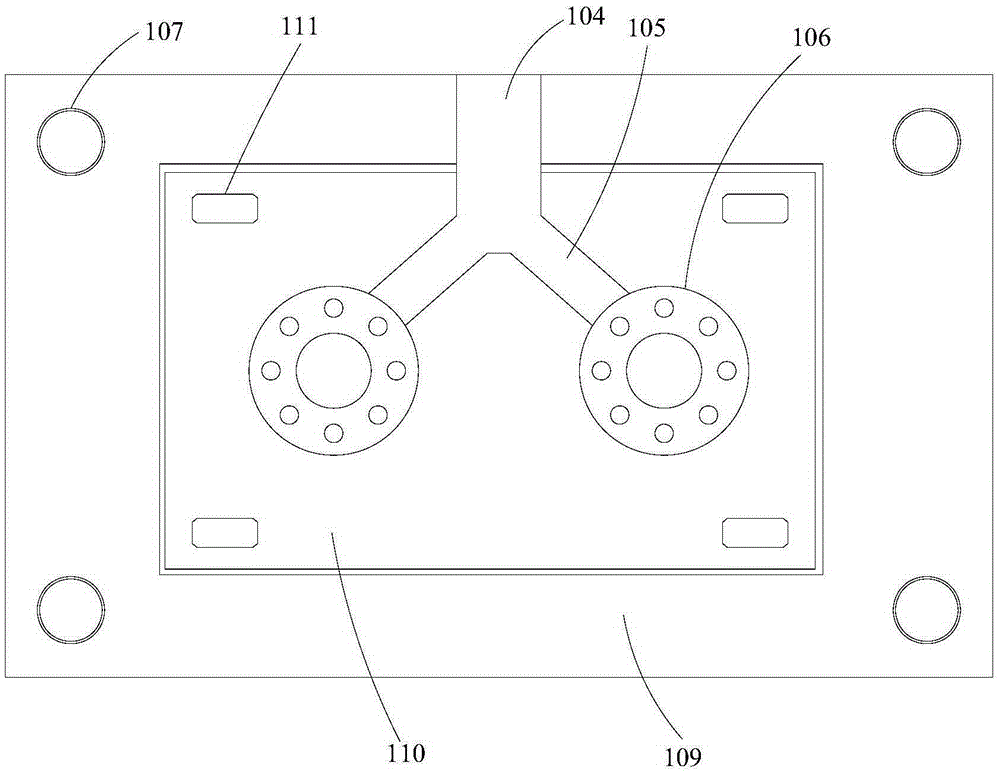

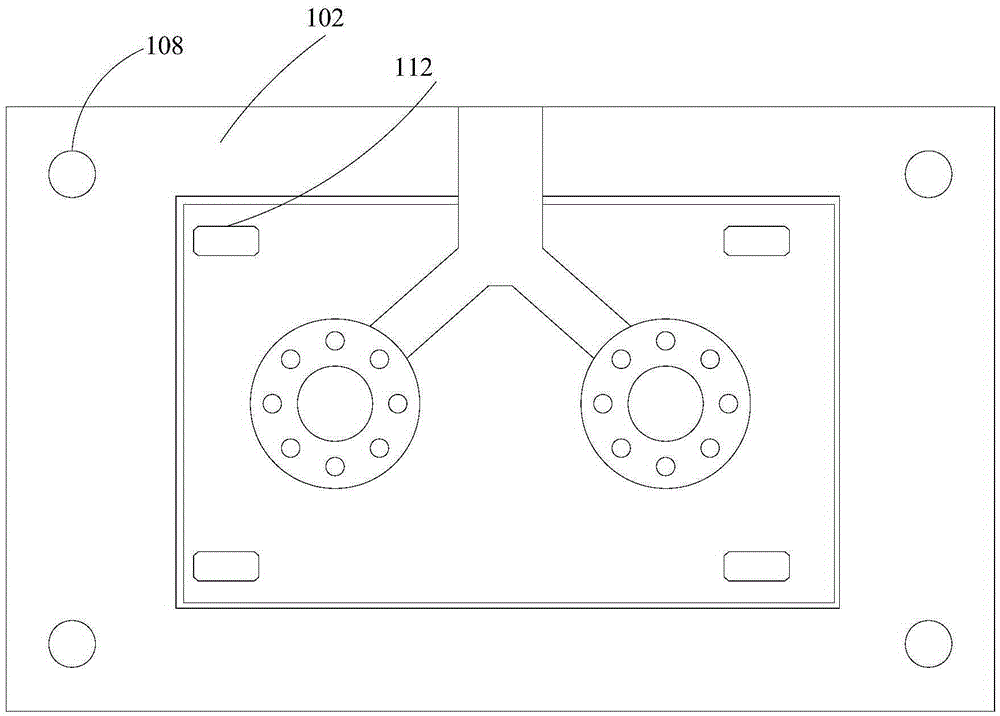

[0068]A kind of processing equipment, comprises machine base, and forming mold and post-processing equipment are arranged at intervals on the machine base, and described forming mold comprises mold body, and this mold body comprises detachably connected upper mold base and lower mold base; The processing equipment comprises a machine base 201, the machine base 201 is provided with an installation platform 202, the installation platform 202 is provided with an installation part 203, and the machine base 201 is also provided with a mobile seat 204 movably connected with it, and the mobile seat 204 is driven by a driving device The moving base 204 is provided with a wire saw machine 205 fixedly connected thereto. The wire saw machine 205 includes a saw blade 206, and the two ends of the saw blade 206 are respectively located on both sides of the installation part 203. The mounting platform 202 is provided with a press-fitting platform 207 that is movably connected with it, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com