Movable tire vulcanization automated device

An automatic device and tire vulcanization technology, which is applied to tires, other household appliances, household appliances, etc., can solve the problems of large investment, achieve the effect of saving investment and improving mechanization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

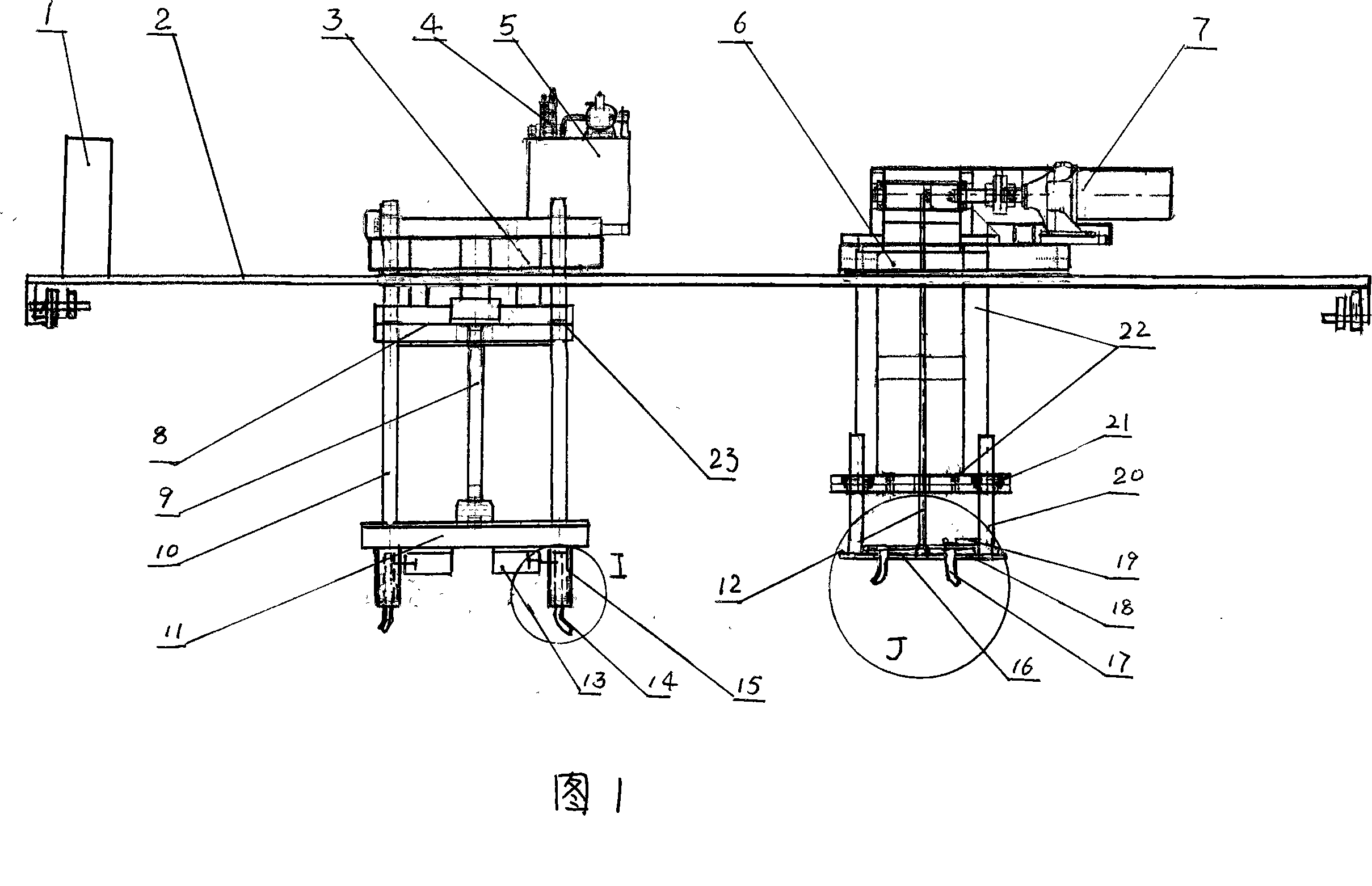

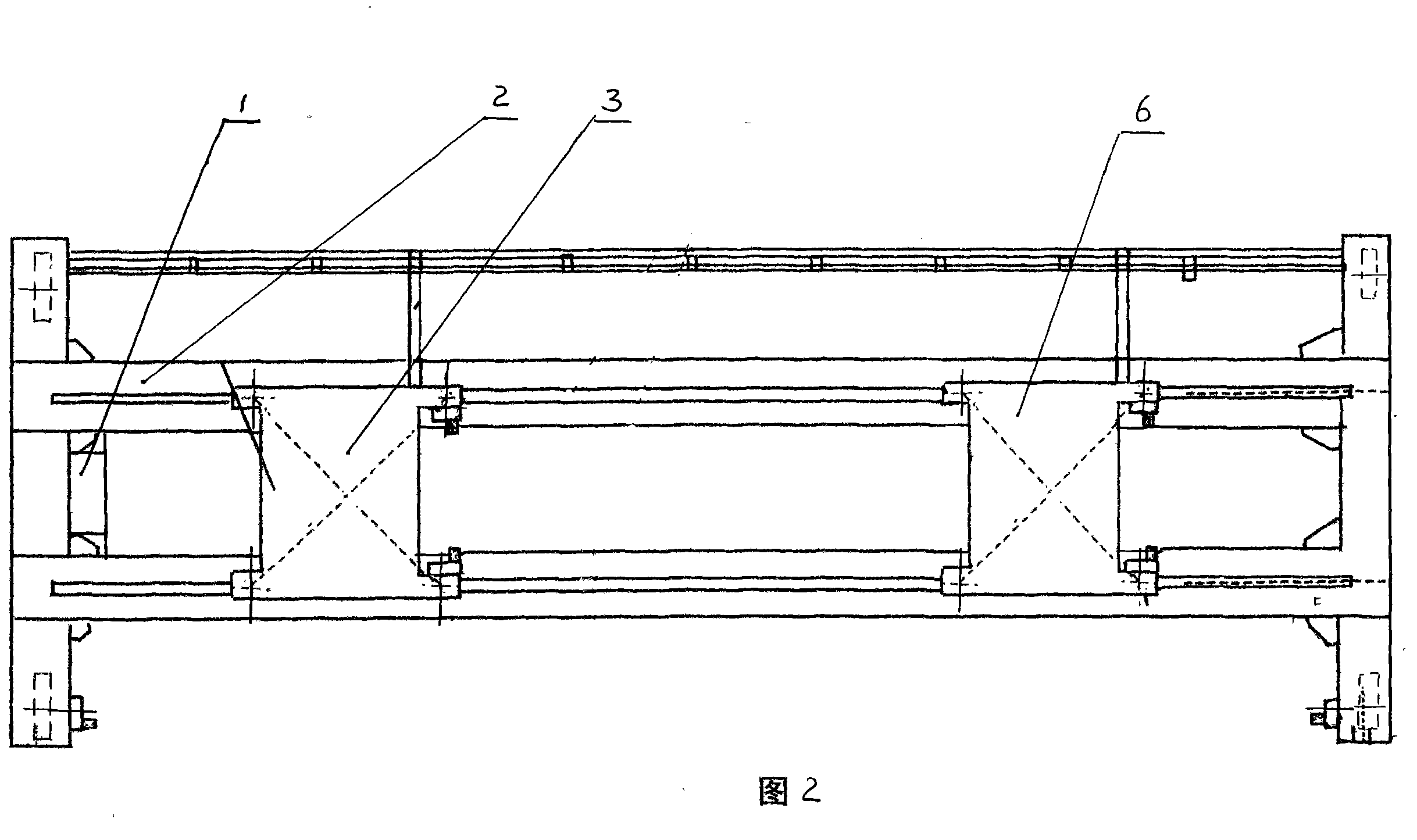

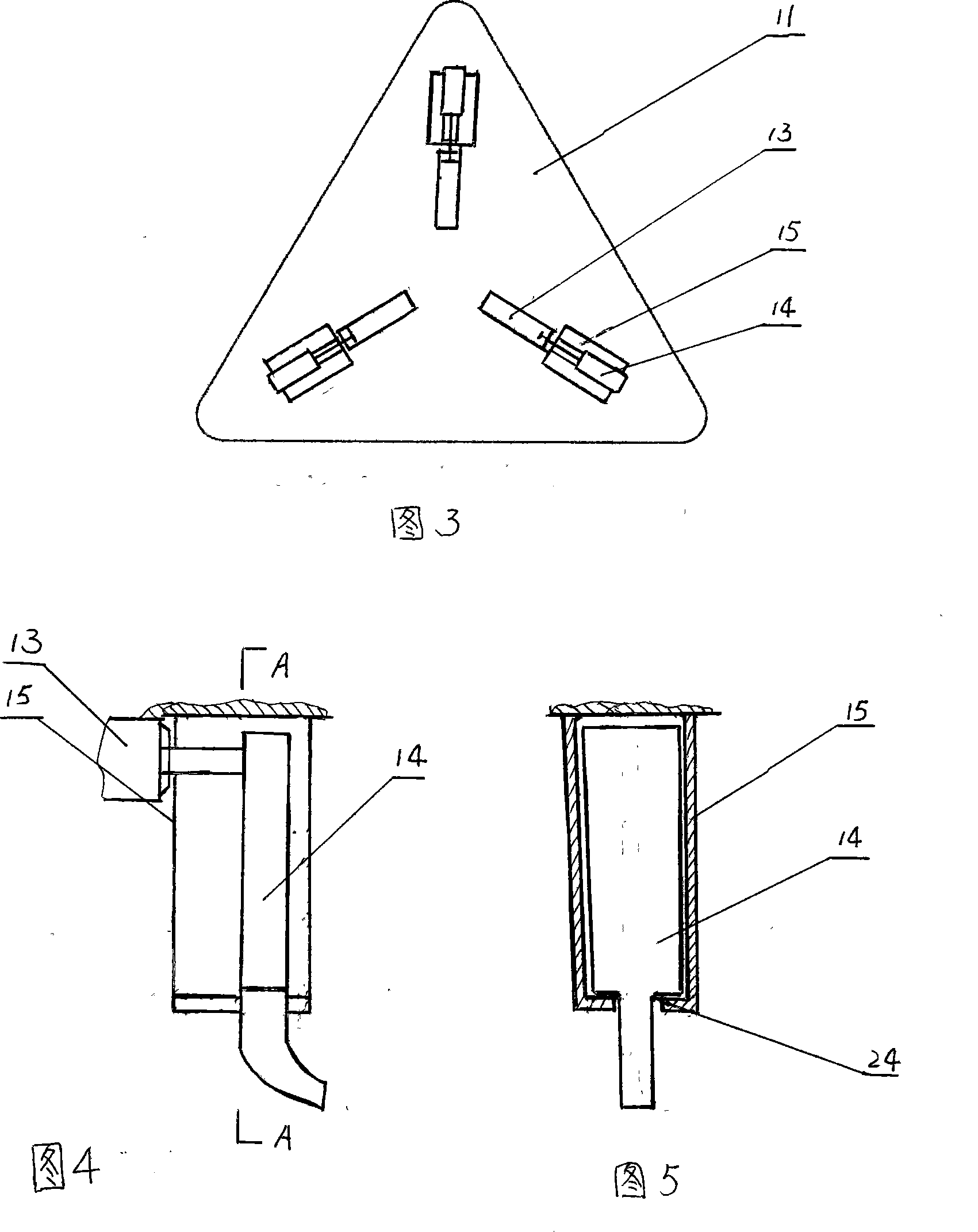

[0025] The tire vulcanization production automation device of the present application is arranged above the vulcanization production line, and its structure is as follows: figure 1 , figure 2 As shown, it includes a mobile double-girder double-track trolley 2, and two four-wheel track sports cars are arranged on the double-girder double-track trolley 2, which are respectively a large sports car 3 and a small sports car 6; a hydraulic pump station is installed on the platform of the large sports car 3 Assembly 5, a guide rail frame 8 and a mold opening manipulator are installed under the big sports car 3; an electric winch 7 is installed on the platform of the small sports car 6, and a guide rail frame 22 and an embryo filling manipulator are installed under the small sports car 6, and the embryo filling manipulator passes through The wire ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com