Mounting method and alignment rod for connecting pin of main piston of actuator and slide block of sensor

A technology of connecting pins and main pistons, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of time-consuming and labor-intensive technical requirements, affecting the accuracy of sensors, and low assembly efficiency, so as to ensure the accuracy of use and shorten the assembly time , The effect of high assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

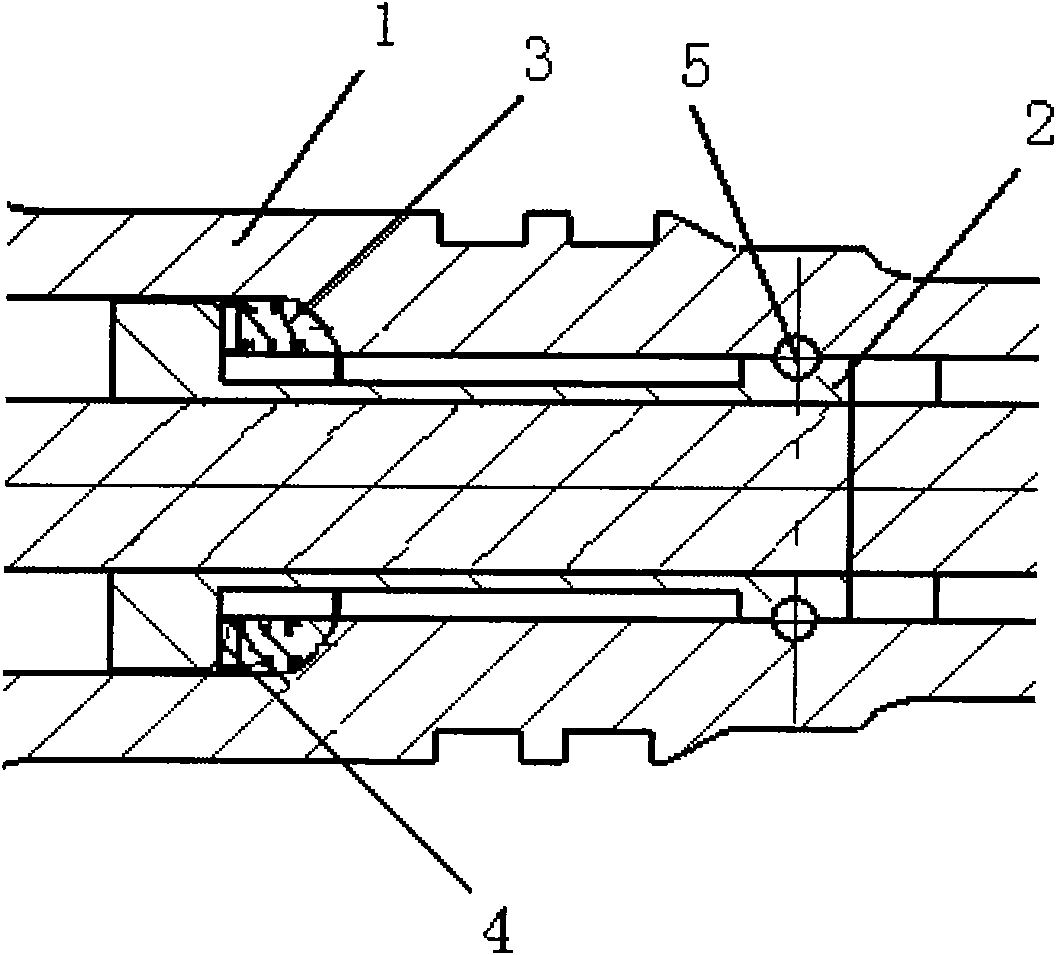

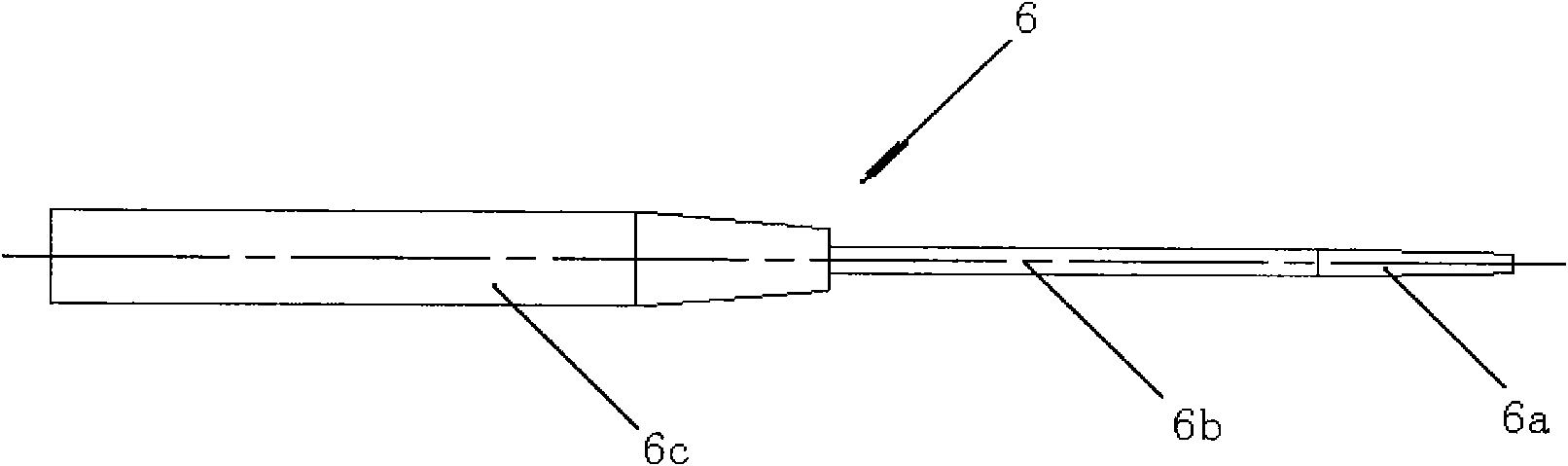

[0018] Embodiment 1, the taper α of the conical section 6a of the leveling rod is 15°, and the diameter of the end of the conical section 6a is 1.8mm. The installation steps are as follows:

[0019] 1. Match the adjusting gasket 4; by matching the adjusting gasket 4 with different thicknesses, the edge of the part where the section of the ring mounting groove on the sensor slider coincides with the mounting hole of the connecting pin on the main piston is along the center of the mounting hole of the connecting pin. The minimum distance in the line direction is 2.2mm;

[0020] 2. Align the center of the cross-section of the annular mounting groove on the sensor slider and the mounting hole of the connecting pin on the main piston;

[0021] 3. Install the connecting pin to complete the installation of the main piston and the connecting pin of the sensor slider.

Embodiment 2

[0022] In Embodiment 2, the taper α of the conical section 6a of the straightening rod is 17°, and the diameter of the end of the conical section 6a is 2mm. The installation steps are as follows:

[0023] 1. Match the adjusting gasket 4; by matching the adjusting gasket 4 with different thicknesses, the edge of the part where the section of the ring mounting groove on the sensor slider coincides with the mounting hole of the connecting pin on the main piston is along the center of the mounting hole of the connecting pin. The minimum distance in the line direction is 2.5mm;

[0024] 2. Align the center of the cross-section of the annular mounting groove on the sensor slider and the mounting hole of the connecting pin on the main piston;

[0025] 3. Install the connecting pin to complete the installation of the main piston and the connecting pin of the sensor slider.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com