Oil immersed CBB60-type alternating current motor capacitor

A CBB60, AC motor technology, applied in the field of capacitors, can solve the problems of time-consuming capacitor filling, high consumption of epoxy resin, environmental pollution, etc., to achieve the effect of maintaining the environment, reducing usage, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

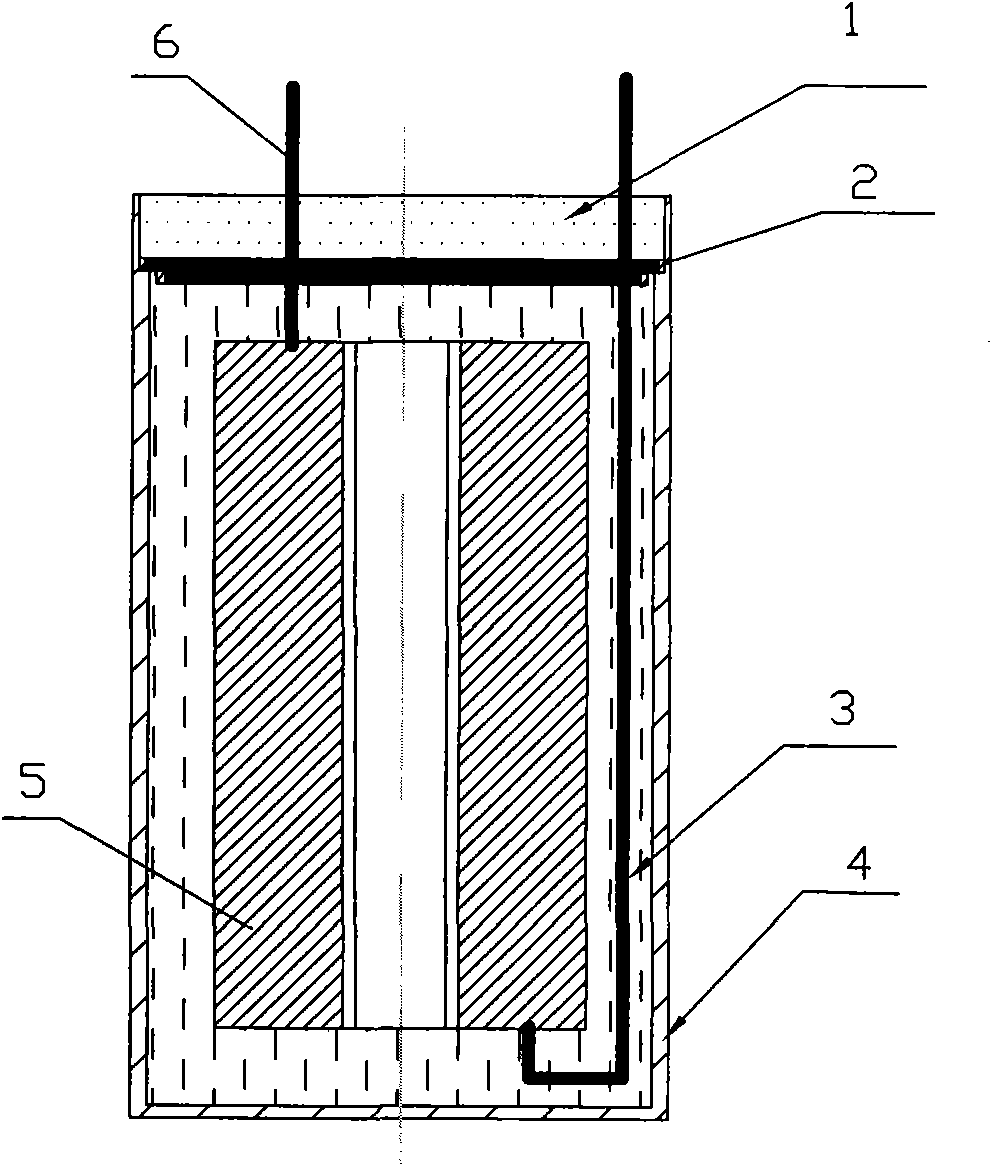

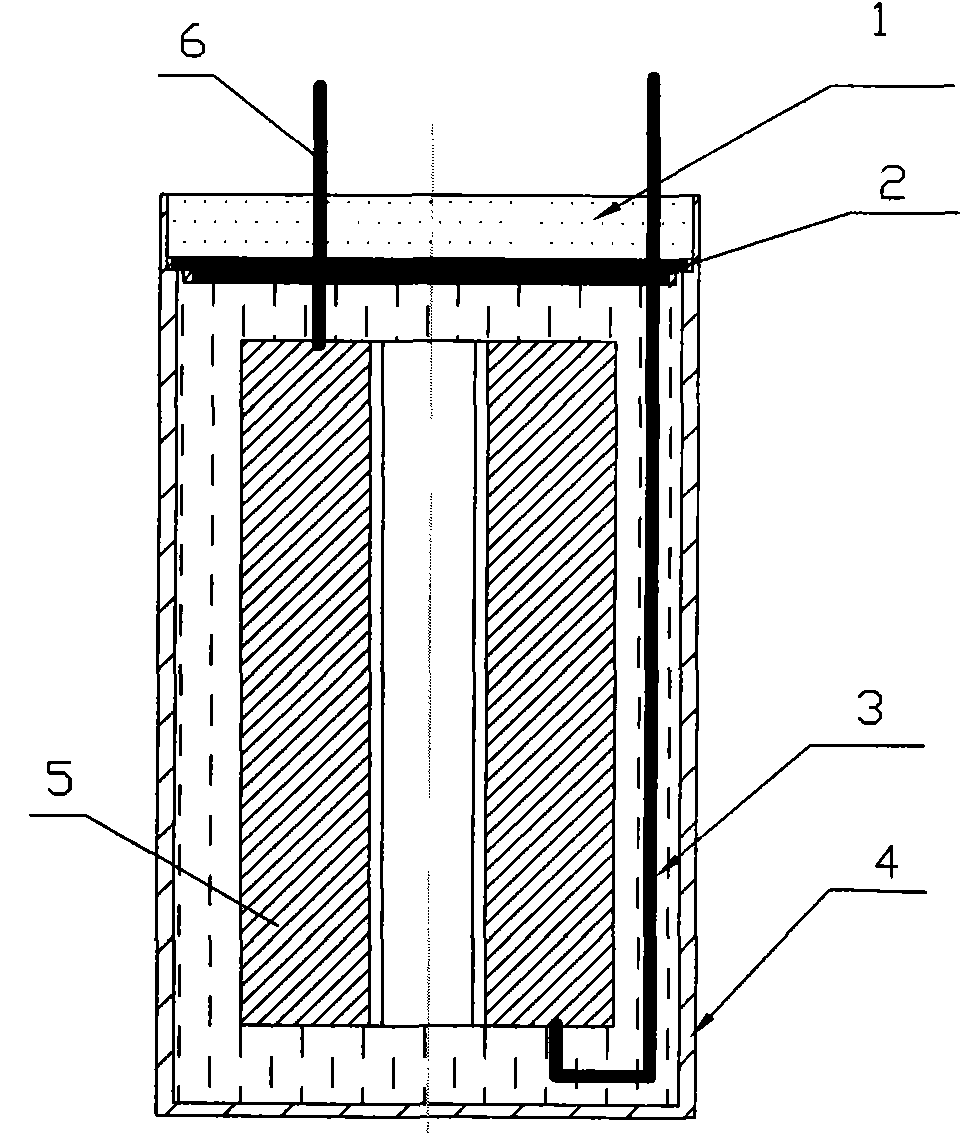

[0008] Oil-immersed CBB60 type AC motor capacitor of the present invention, as figure 1 As shown, it includes a cylindrical shell 4 and a capacitor core 5 located in the cylindrical shell 4, and it also includes a cover 2 covered with an epoxy resin layer 1, which forms a sealing body together with the shell 4, and is sealed. There is castor oil 3 between the capacitor core 5 and the shell 4 in the body, and the lower part of the lead-out terminal 6 is electrically connected to the capacitor core 5 through the epoxy resin layer 1 and the cover 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com