Mesoporous molecular sieve catalyst for catalytic cracking of waste plastics as well as preparation method and application thereof

A technology of mesoporous molecular sieves and waste plastics, which is applied in the field of catalysts for catalytic cracking of waste plastics. It can solve the problems of low yield, low quality of oil products, and difficulty in regulating the surface acidity of mesoporous molecular sieves. active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

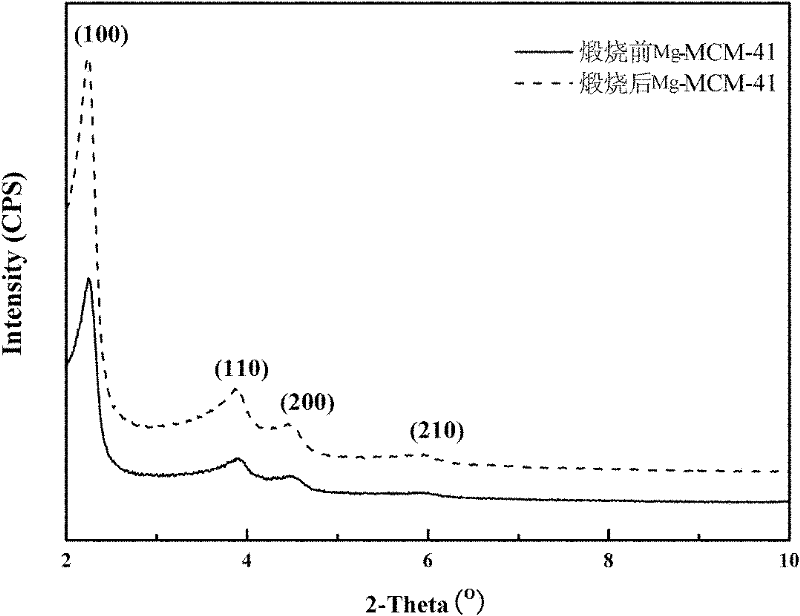

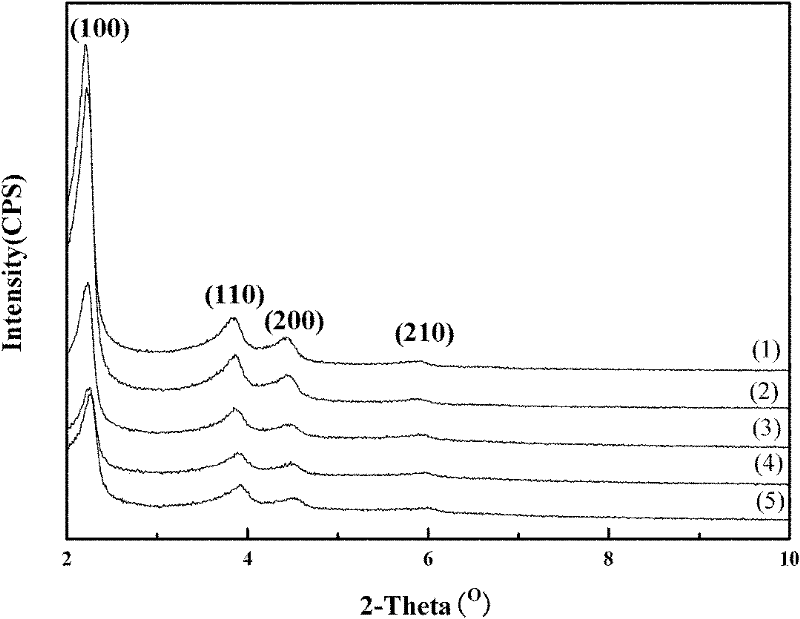

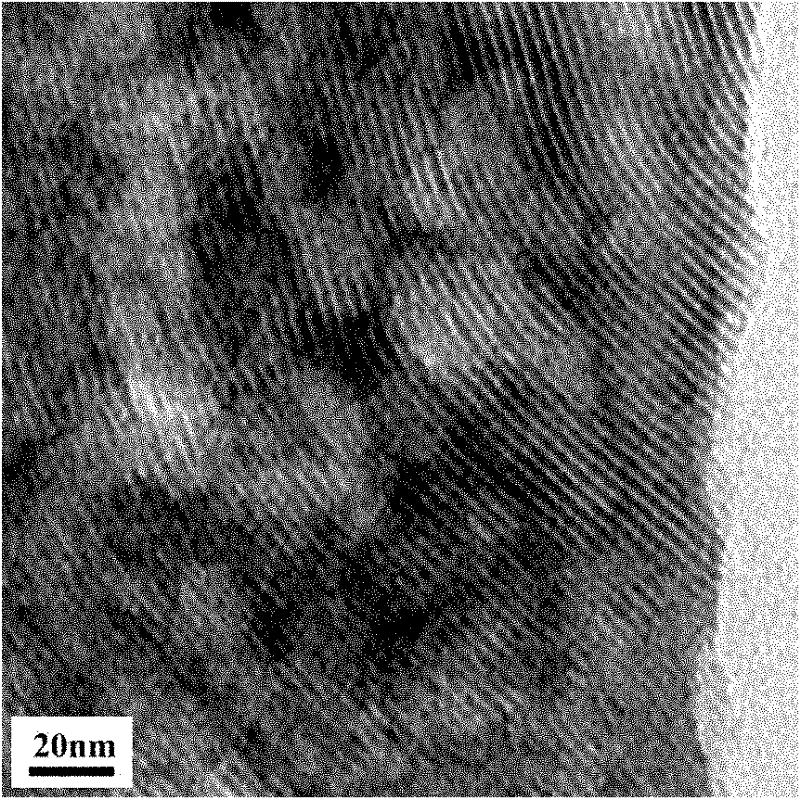

[0029] (1) Preparation of mesoporous molecular sieve catalyst: After natural sepiolite is treated with 1M sulfuric acid for 5h, the sepiolite with Mg content of 10.3% is obtained, activated in alkaline sodium hydroxide solution, and the activated alkalinity is 10g / L ; When synthesized, the molar ratio is n(CTAB):n(SiO 2 ):n(H 2 O)=1.0:2.5:500 take CTAB and sepiolite. Dissolve CTAB in deionized water, slowly add alkali to activate sepiolite, adjust the pH to 11 with hydrochloric acid (1mol / L), and stir magnetically for 5h. Then the mixture was poured into a polytetrafluoroethylene reactor and crystallized at 100°C for 24h. The crystallized mixed solution was washed, dried and placed in a muffle furnace. First, the temperature was slowly raised to 250°C, kept for 2 hours, then slowly raised to 550°C, kept for 4 hours, and then lowered to room temperature to obtain the carrier Mg-MCM-41 , specific surface area 928m 2 / g, pore diameter 2.94nm, pore volume 1.04cm 3 / g. Weigh ...

Embodiment 2

[0032] (1) The magnesium mesoporous molecular sieve type catalyst carrier is prepared according to the process of Example 1, and the Mg content is adjusted to 18%, to obtain a Mg-MCM-41 specific surface area of 908m 2 / g, pore diameter 2.84nm, pore volume 1.01cm 3 / g. Weigh a certain amount of Mg-MCM-41 and activate it at 200°C for 1 hour, then use it. Measure TiCl4 2ml (according to 10% of the amount of Mg-MCM-41), dispersed in 50ml of ethanol, added Mg-MCM-41, stirred for 3h. Then it was dried at 80°C for 8h to obtain a white powder. After the white powder is granulated, it is calcined at 500°C for 4 hours in a muffle furnace to obtain a mesoporous molecular sieve catalyst TiO for catalytic cracking of waste plastics. 2 / Mg-MCM-41, specific surface area 778m 2 / g, pore diameter 2.68nm, pore volume 0.80cm 3 / g

[0033] (2) Catalytic cracking process of waste plastics: wash waste plastics, crush them, pass through a 5mm mesh screen, and add mesoporous molecular sieve c...

Embodiment 3

[0035] (1) The magnesium mesoporous molecular sieve type catalyst support is prepared according to the process of Example 1, and the Mg content is adjusted to 0.5%, to obtain Mg-MCM-41 with a specific surface area of 1013m 2 / g, pore diameter 3.01nm, pore volume 1.13cm 3 / g. A certain amount of Mg-MCM-41 was weighed and activated at 100°C for 3 hours, and then used. Weigh ammonium molybdate (according to 15% of the amount of MCM-41), disperse in 70ml of toluene, add Mg-MCM-41, and stir at 60°C for 2h. Then dry at 90° C. for 0.5 h to obtain a light yellow powder, and soak the powder in 15 g / L nickel nitrate solution for 30 minutes to obtain a gray powder. After the gray powder is granulated, it is calcined at 550°C for 2 hours in a muffle furnace to obtain a mesoporous molecular sieve catalyst (MoO 3 , NiO) / Mg-MCM-41, specific surface area 813m 2 / g, pore diameter 2.81nm, pore volume 0.91cm 3 / g

[0036] (2) Catalytic cracking process of waste plastics: wash waste plast...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com