Decoupled tri-rotation parallel mechanism

A three-rotation, parallel technology, used in manipulators, program-controlled manipulators, metal processing mechanical parts, etc., can solve the problems of low motion accuracy, complex structure, inconvenient control, etc., and achieve the effect of small moment of inertia, simple control, and simple structure

Inactive Publication Date: 2011-01-05

SHANGHAI UNIV OF ENG SCI

View PDF8 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The purpose of the present invention is to provide a decoupled three-rotation parallel mechanism to overcome the defects of complex structure, inconvenient control and low motion precision in the prior art

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

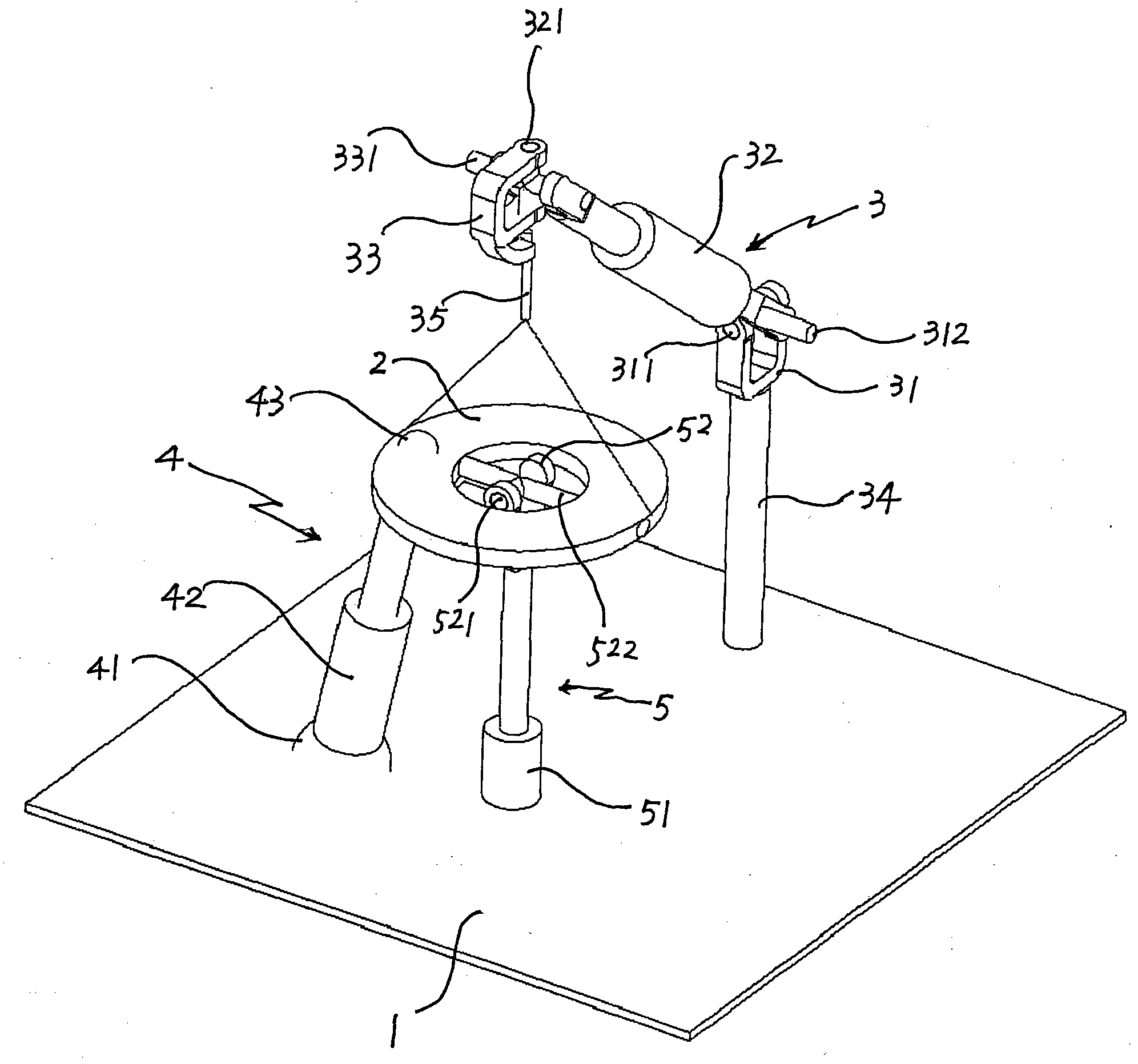

The invention provides a decoupled tri-rotation parallel mechanism, which comprises a stand, a moving platform, a first moving branch chain, a second moving branch chain and a third moving branch chain, wherein the first moving branch chain, the second moving branch chain and the third moving branch chain are connected between the stand and the moving platform. The first moving branch chain comprises a first universal hinge, a first moving pair and a second universal hinge which are sequentially connected; the second moving branch chain comprises a first spherical hinge, a second moving pair and a second spherical hinge which are sequentially connected; and the third moving branch comprises a rotation pair and a third universal hinge which are sequentially connected. The invention has three decouple rotational degrees of freedom, and the rotational freedom degree of freedom only depends on the linear control of the moving pair of the moving branch chains, therefore, the implementation principle is very simple and the mechanism has quite good linear relation.

Description

Decoupled three-rotation parallel mechanism technical field The invention relates to a machine tool and an industrial robot, in particular to a three-rotation parallel mechanism for decoupling a virtual-axis numerical control machine tool with a parallel structure and a parallel robot. Background technique Parallel mechanisms are widely used in heavy-duty simulation equipment, robots, CNC machine tools, sensors and micro-operation fields. However, the driving units of the parallel mechanism are coupled, that is, the movement of the overall output platform (moving platform) of the parallel mechanism in any direction is the synthesis of the movements of all driving units, and the movement of each driving unit is combined with the overall movement of the parallel mechanism ( That is, the relationship between input and output) is nonlinear. This characteristic leads to complex control of parallel mechanism, difficult calibration, and restricts the improvement of accuracy. Th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B25J9/08B23Q1/44

Inventor 张帆徐新成胡义刚朱建军刘燕宋芳

Owner SHANGHAI UNIV OF ENG SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com