Assembly type hollow slab bridge adopting bracket to replace ribbet to transmit force

A hollow slab bridge, prefabricated technology, applied in the erection/assembly of bridges, bridges, bridge parts, etc., can solve the problems of poor lateral integrity, limited ability to transmit shear force, damage to the pavement layer, etc., to simplify prefabrication and construction. Process, homogenize load lateral distribution, improve the effect of dynamic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

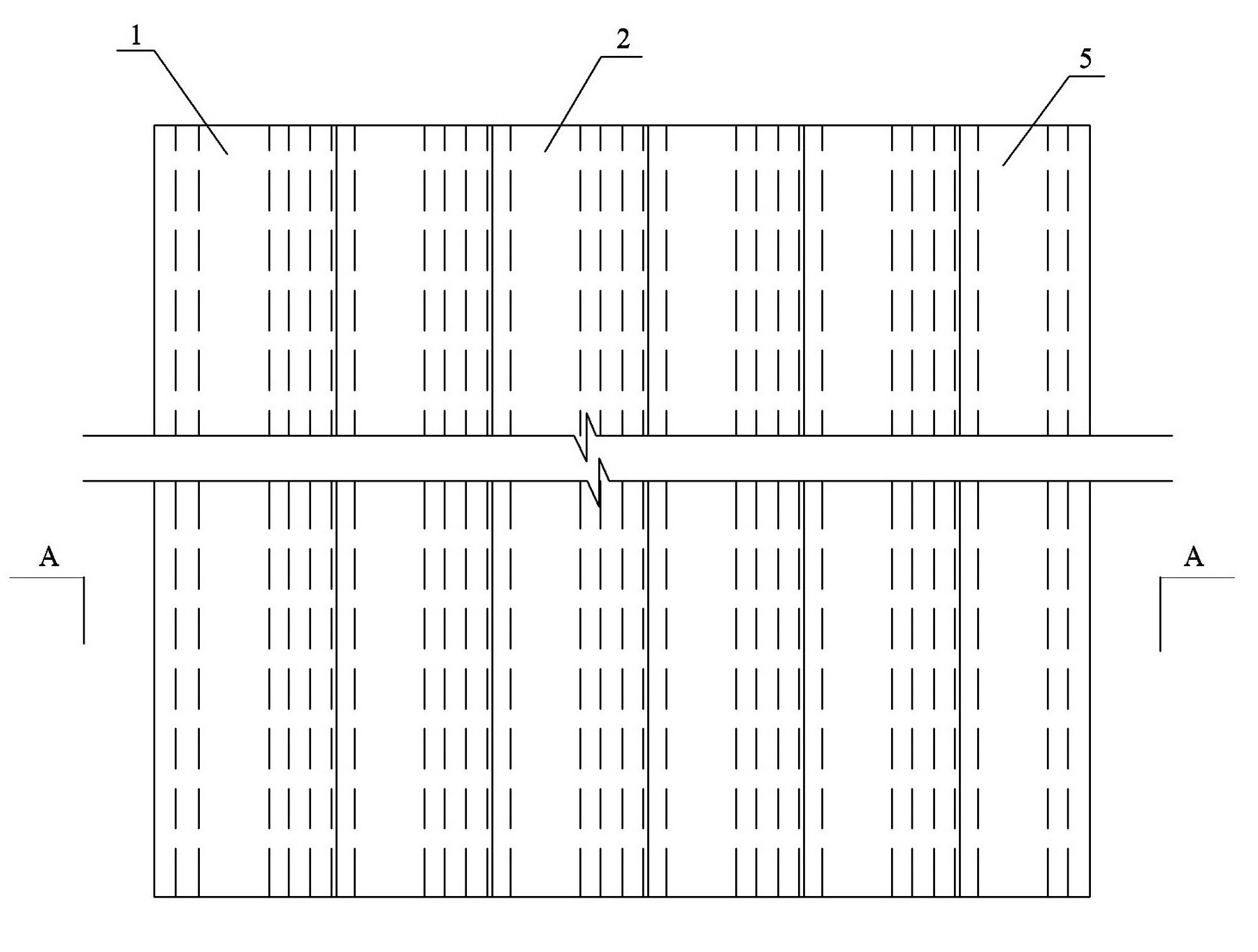

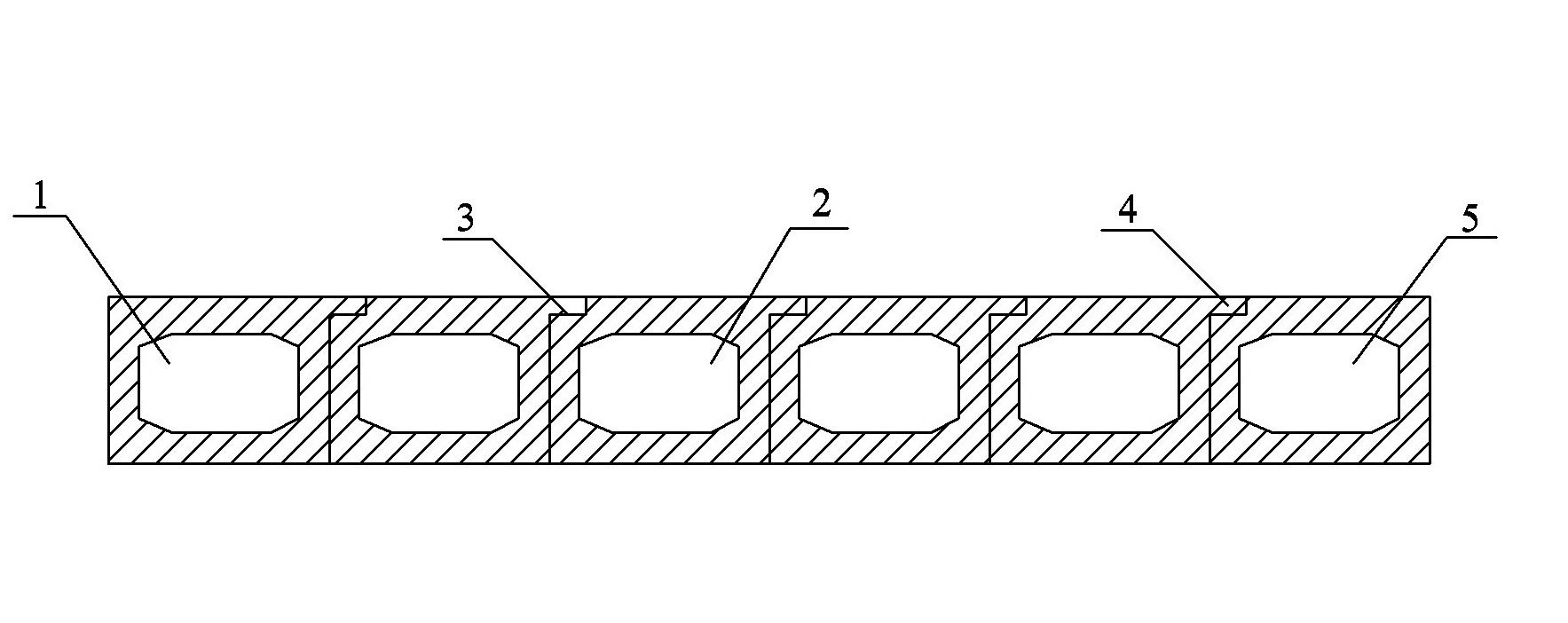

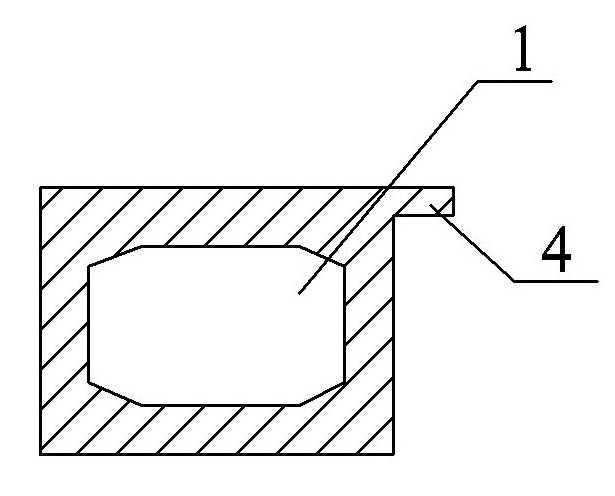

[0027] Example 1 Assembled hollow slab bridge using corbels instead of grooved joints for force transmission, see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , its construction method includes the following steps:

[0028] (1) Prefabricated assembled hollow slabs: prefabricated hollow slabs in the prefabrication factory according to the design requirements. The side of the hollow slab is a straight line. For the middle plate of the prefabricated hollow slab, part of the concrete on the side of the joint between the web and the roof is removed (according to calculation and structural requirements, the shortest side of the removed concrete section is generally not less than 1 / of the thickness of the roof. 2), the notch forms the support surface 3 of the corbel, and the protruding corbel 4 is prefabricated on the other side of the plate; for the side plates 1 and 5 of the assembled hollow plate, the corresponding inner plate is constructed on the inside of the jo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com