Aerated underbalanced drilling method for coal-bed gas

An underbalanced drilling and coalbed methane technology, which is applied in directional drilling, earthwork drilling, and flushing of boreholes, etc., can solve problems such as inability to break away cuttings, stuck drill, and affect drilling work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

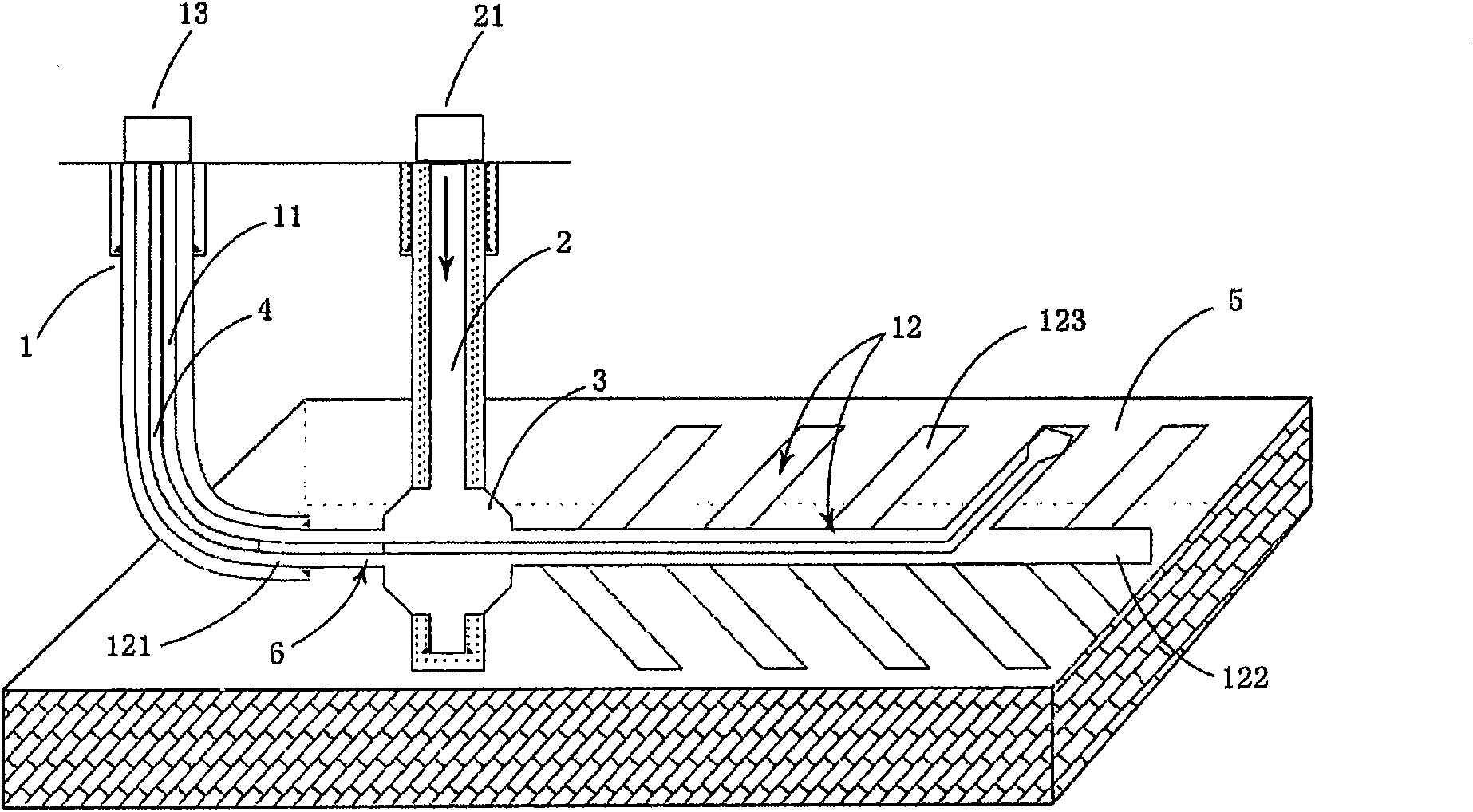

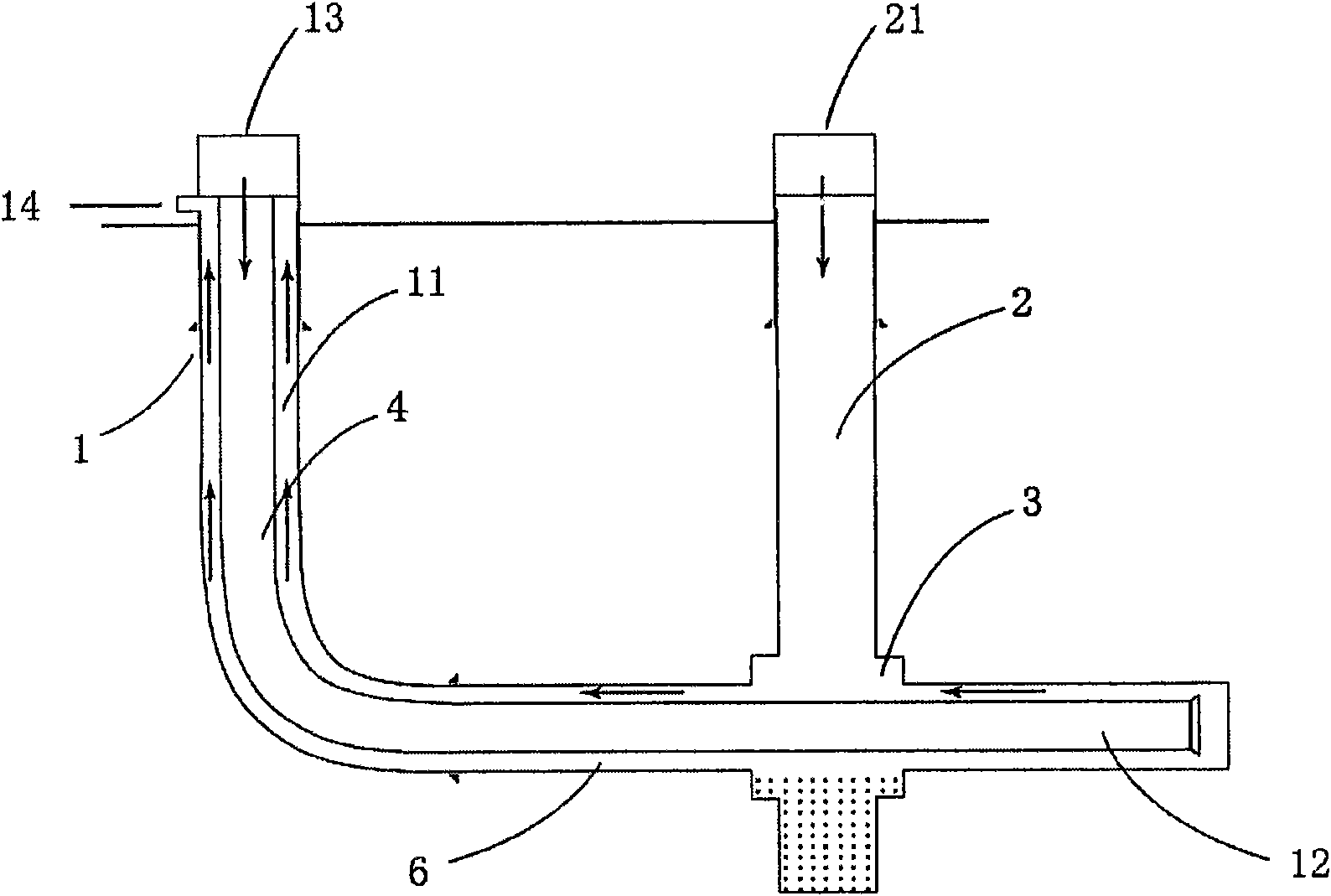

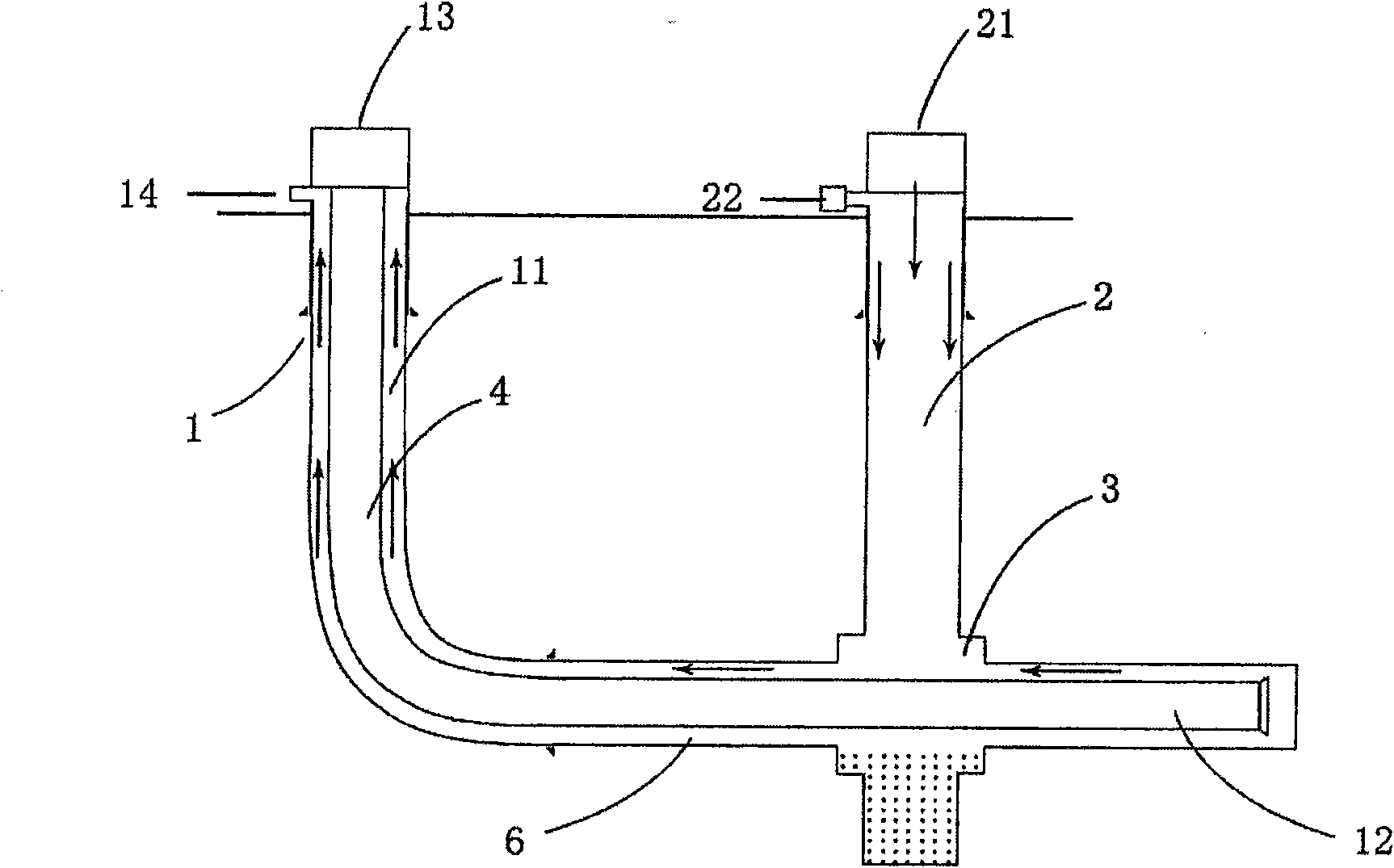

[0026] In order to better understand the present invention, first combine figure 1 with figure 2 A brief introduction is given to the aerated underbalanced drilling method used in coalbed methane in the prior art.

[0027] Such as figure 1As shown, in the gas-filled underbalanced drilling project for coalbed methane in the prior art, a vertical well 2 is drilled from the ground at the position where the coalbed methane is to be exploited, and a cave 3 is built in the coal seam section below the vertical well 2 . During the formation of the vertical well 2, generally 177.8 mm (also referred to as 7 inches) casing is put into the vertical well 2 to form the wall of the vertical well shaft, and can form a good fluid channel and prevent the vertical well from collapsing. A horizontal well 1 is drilled at a conventional distance from the vertical well 2, for example at a distance of about 100-350 meters. After the horizontal well 1 undergoes the traditional one-drilling, two-dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com