Luminescent module, and its manufacturing method

A light-emitting component and manufacturing method technology, applied in the direction of electrical components, semiconductor devices, electric solid devices, etc., can solve the problems of sealing resin peeling, insufficient adhesion, and inability to fully dissipate heat, and achieve the goal of reducing the number of parts and reducing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

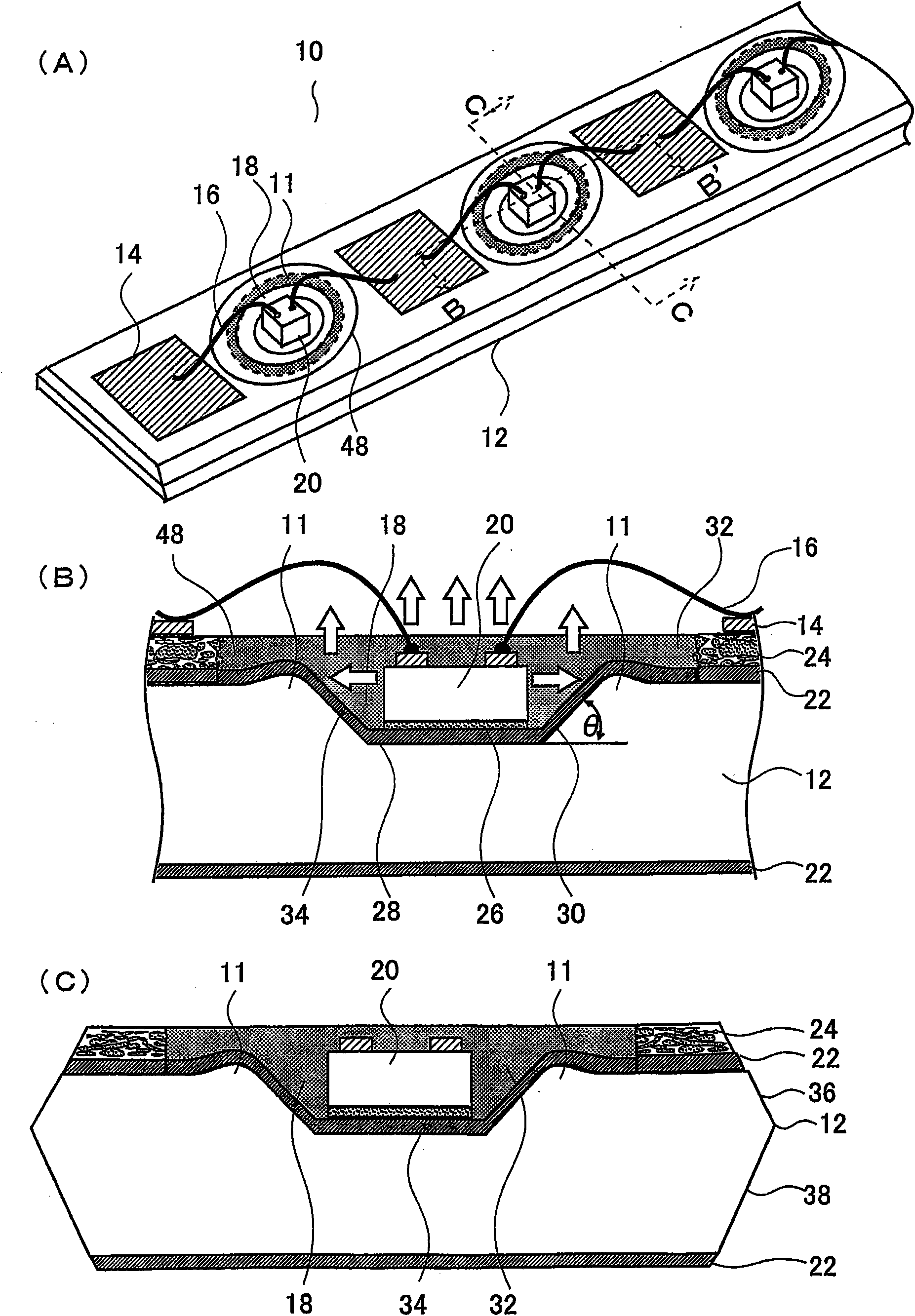

[0055] refer to figure 1 The structure of the light emitting module 10 of the present invention will be described. figure 1 Among them, (A) is a perspective view of the light emitting module 10, (B) is a cross-sectional view of line B-B' of (A), and (C) is a cross-sectional view of line C-C' of (A).

[0056]Referring to these drawings, the light-emitting assembly 10 mainly includes a metal substrate 12, a conductive pattern 14 formed on the upper surface of the metal substrate 12, a concave portion 18 formed by making a part of the upper surface of the metal substrate 12 concave, and the surrounding area of the concave portion 18. The upper surface of the metal substrate 12 has a convex portion 11 formed in a convex shape, a light emitting element 20 housed in the concave portion 18 , and a sealing resin 32 covering the light emitting element 20 .

[0057] refer to figure 1 (A), the light emitting module 10 has a plurality of light emitting elements 20 mounted on the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com