COB (Chip On Board) automatic sorting unit

A technology of automatic sorting and detection device, applied in sorting and other directions, can solve problems such as gold wire damage, and achieve the effect of efficient transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

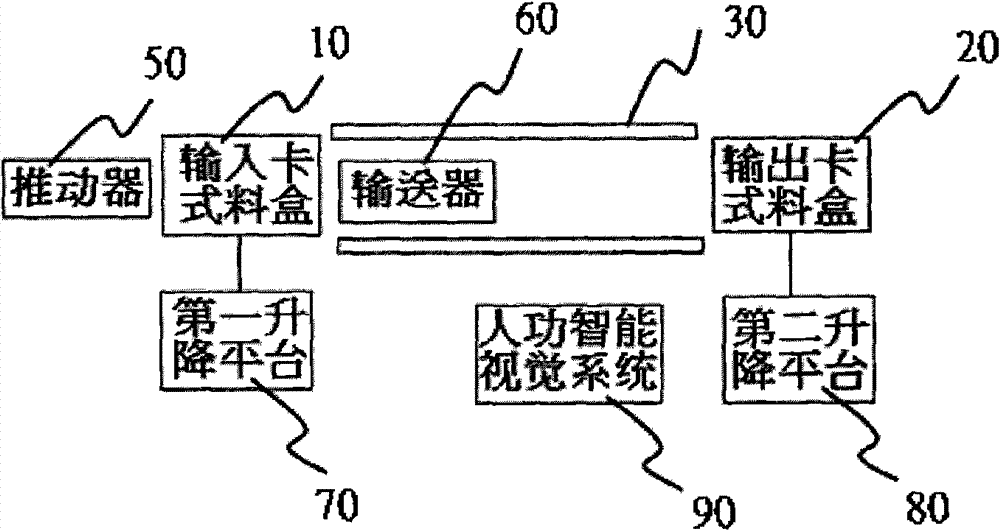

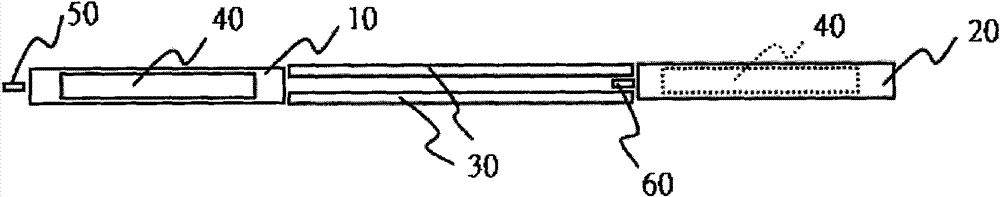

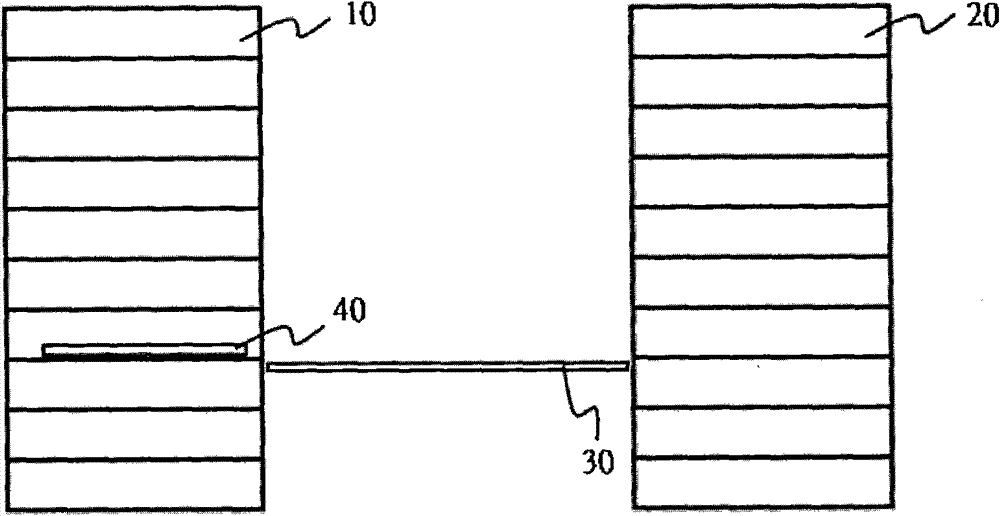

[0041] see Figure 1-5 As shown, the present invention provides a COB automatic sorting device, which includes a test material track 30; one end of the test material track 30 is provided with an input cassette 10, and the other end of the test material track 30 is provided with an output The cassette 20, wherein the input cassette 10 is provided with several input slots, the input slots are arranged in layers up and down, and each of the input slots carries a COB Material strip 40; the output cassette 20 is provided with several output slots, the output slots are arranged in layers up and down, and the output slots respectively carry a COB material strip 40; And one side of the input cassette 10 is provided with a pusher 50, and the pusher 50 moves back and forth to drive the single-layer COB material strip 40 to move linearly, and the COB ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com