Anti-skidding wheel

A non-slip, wheel technology, applied to wheels with shovel-shaped gripping teeth, etc., can solve the problems of tying up trouble, damage to the vehicle cover, uncontrollable wheels, etc., to achieve the effect of simple operation and prevent tire leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to express the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings.

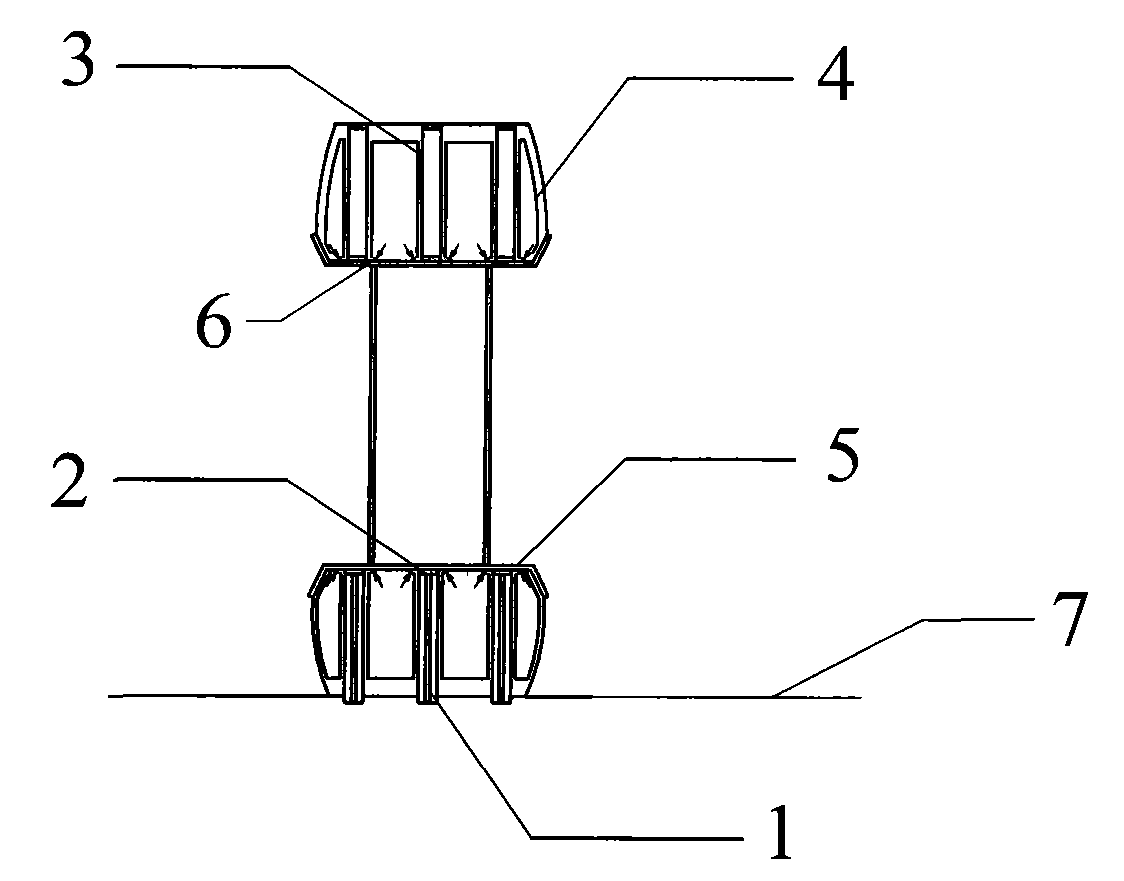

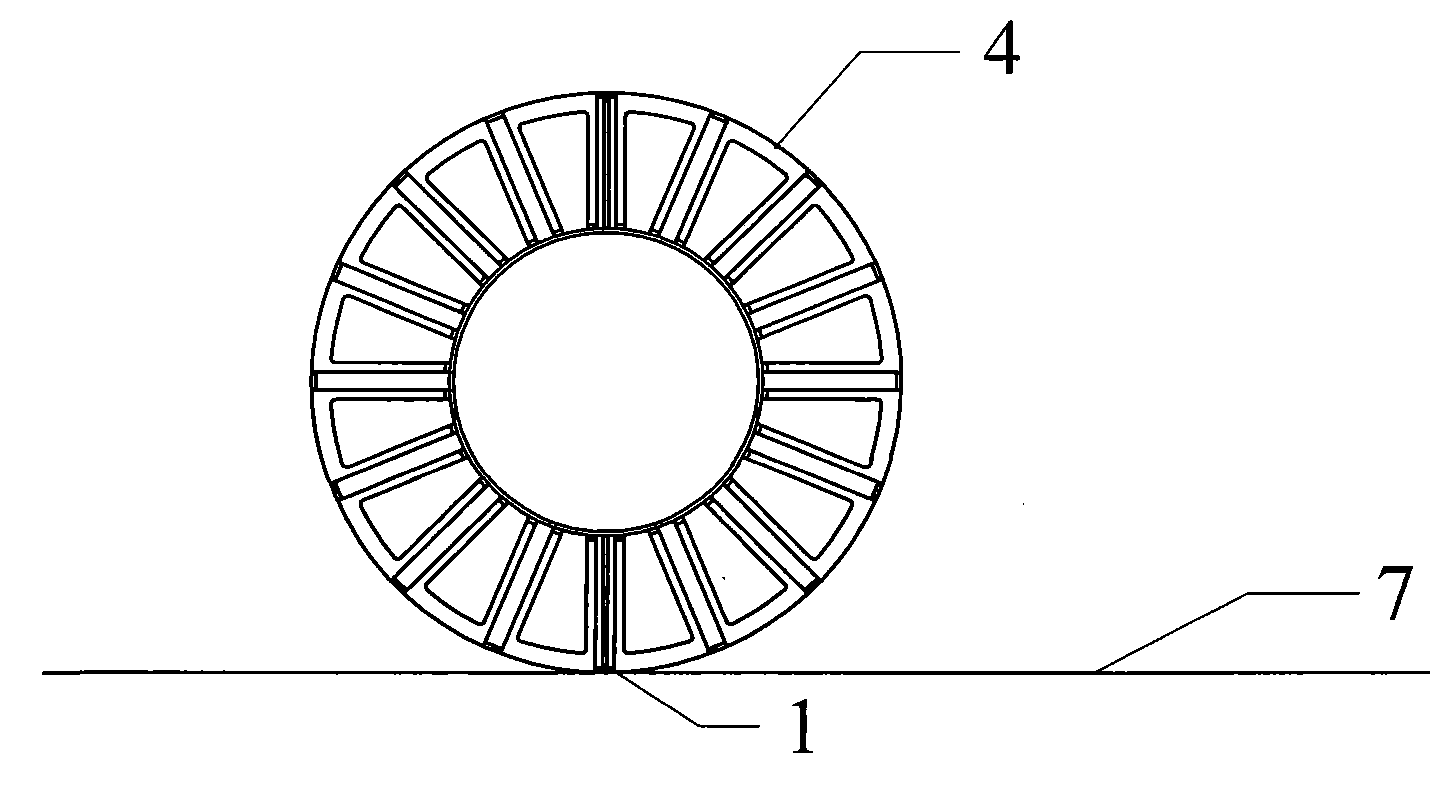

[0017] like figure 1 Shown, the present invention has been provided with antiskid section steel on wheel. The anti-skid section steel is made up of Y-shaped anti-skid claw 1 and anti-skid claw pad 2. The Y-type anti-skid claw 1 is placed in the anti-skid sleeve 3, the Y-type anti-skid claw 1 is fixedly connected with the anti-skid claw pad 2, and the leak-proof support 6 and the anti-skid claw pad 2 are connected with the wheel rim 5.

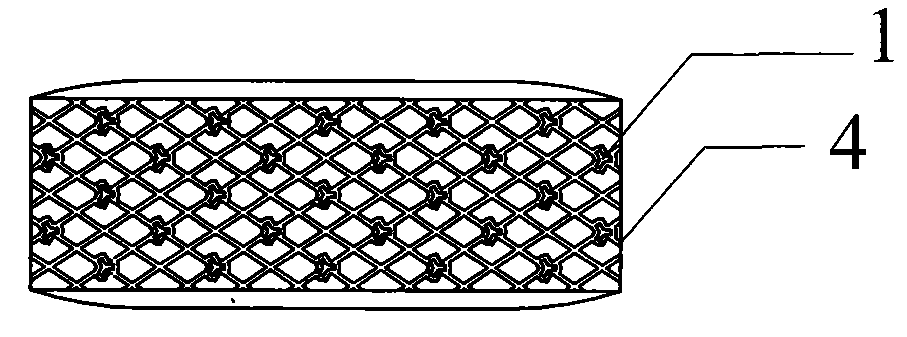

[0018] like Figure 2 to Figure 4 As shown, one end of the Y-type anti-skid claw 1 is located in the depression on the outer surface of the tire 4, and the other end is in the anti-skid sleeve 3 to withstand the steel ring. When the vehicle is running normally, the Y-type anti-skid claw 1 is lower than the surface of the tire 4, and the tire 4 When the air pressure decreased, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com