Improved structure of transferring belt conveyer

A belt conveyor and improved structure technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of being unable to be sent away, and achieve the effects of reduced floor space, large operating space, and compact design structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

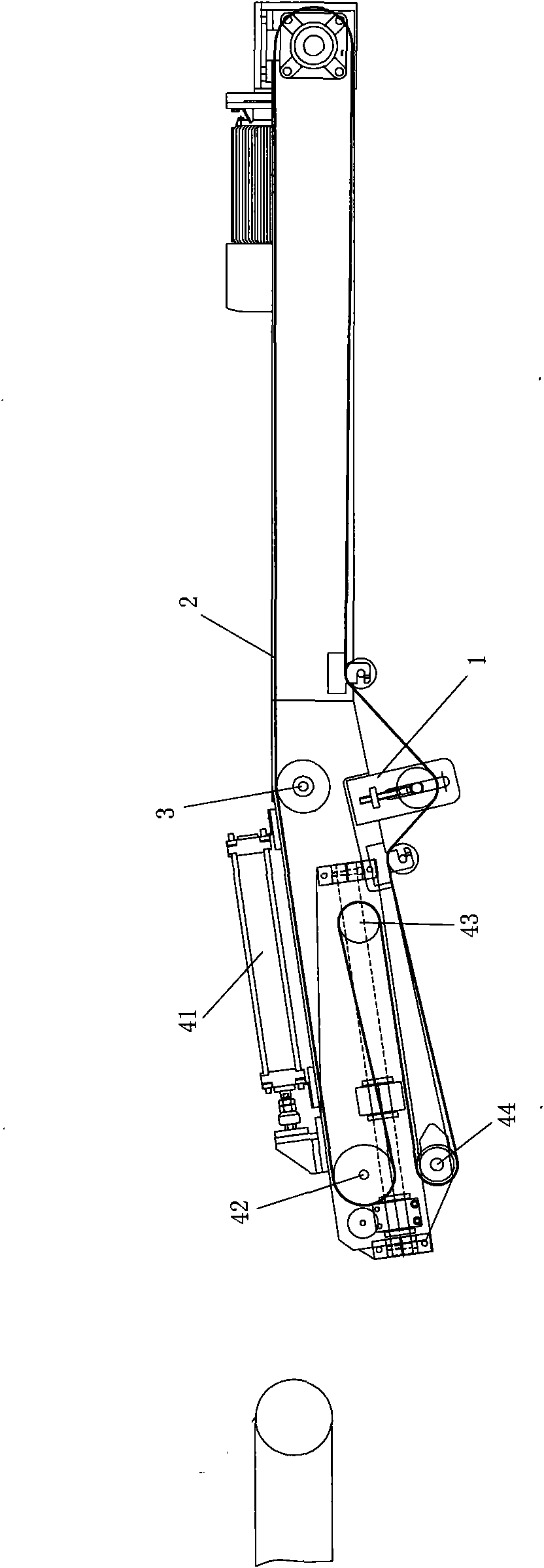

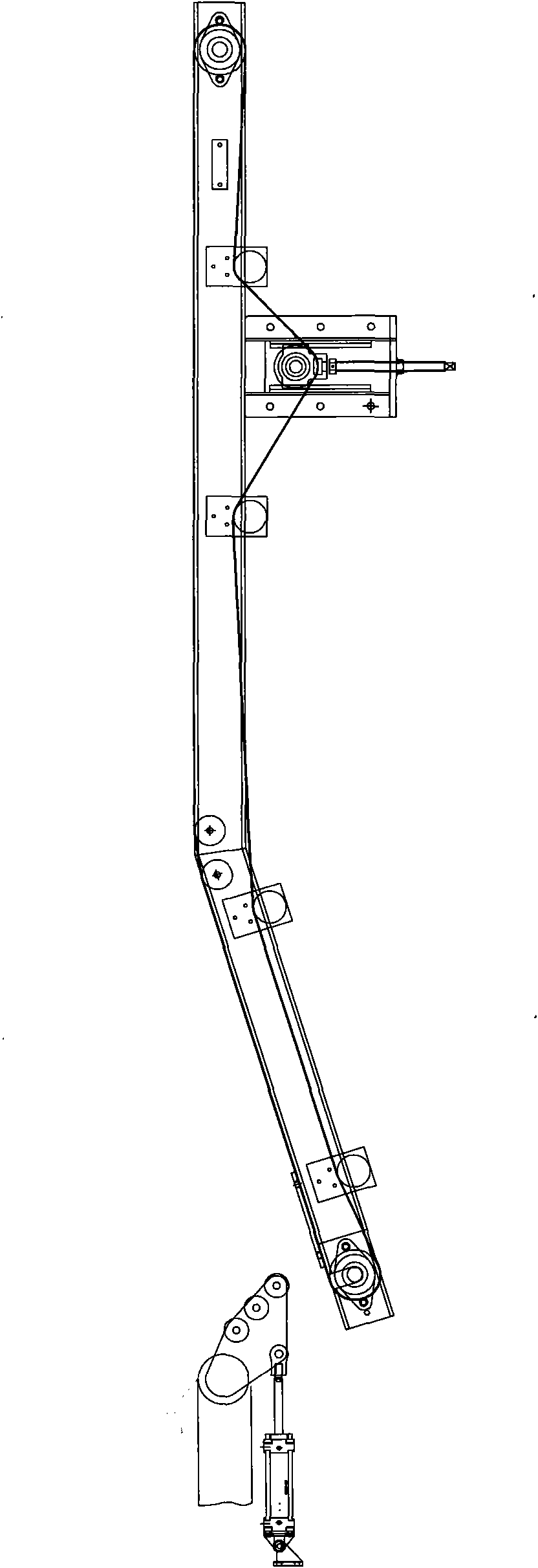

[0010] Embodiment: An improved structure of a pick-up belt conveyor, which includes a fixed frame 1, a conveyor belt 2 and a roller 3, the conveyor belt 2 is wound on the fixed frame 1, and the conveyor belt 2 is arranged on the frame by The roller 3 is driven, and one end of the fixed frame 1 is provided with a telescopic end 4, and the telescopic end 4 includes a driving device 41, a driving roller 42, a number of driven rollers 43 and a positioning roller 44, and the driving device 41 is fixed on the machine. The frame is connected to drive the telescopic movement of the driving roller toward one side of the frame, the passive roller 43 is fixed on the telescopic end of the frame and can telescopically move toward the driving direction of the driving roller, and the positioning roller 44 is fixed on the telescopic end of the frame, The conveyor belt 2 is wound on the driving roller 42, several driven rollers 43 and positioning rollers 44 to connect and drive at the same time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com