Air suction valve sheet structure for refrigeration compressor

A technology for refrigeration compressors and suction valve sheets, which is applied in mechanical equipment, machines/engines, liquid variable capacity machinery, etc. The bending motion of the reed is stable, the efficiency is improved, and the effective flow area is improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

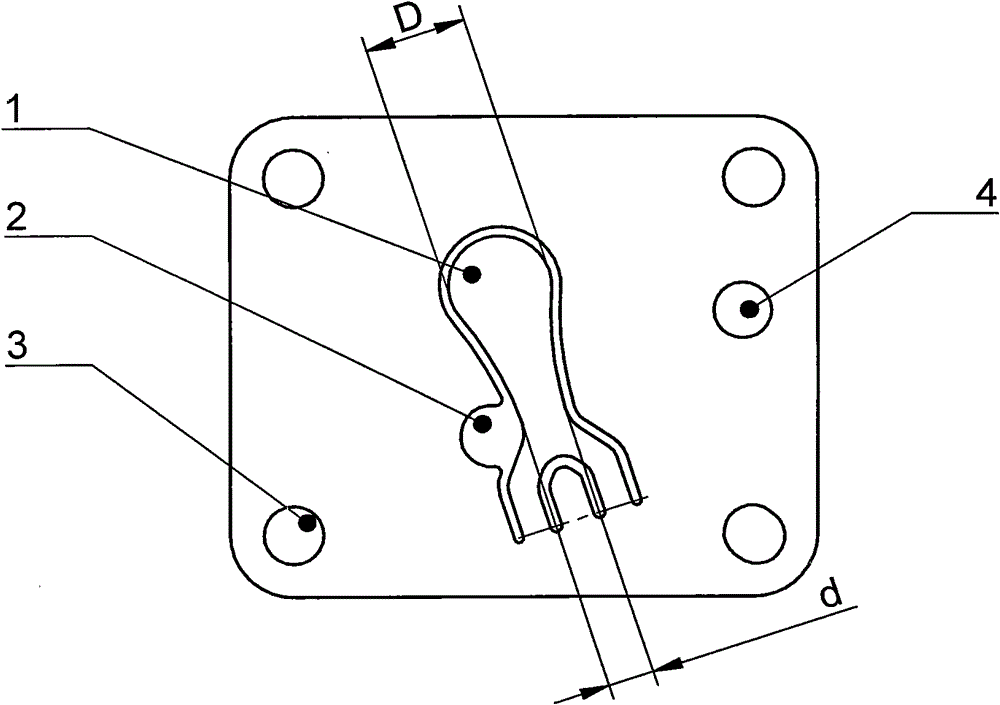

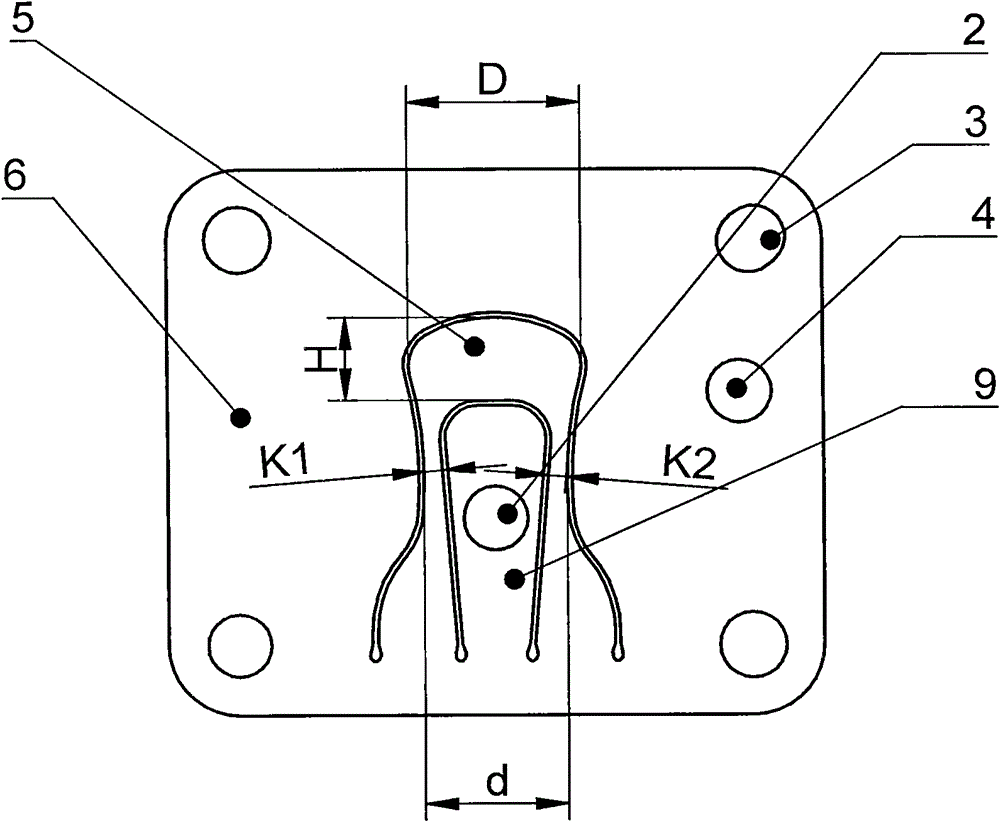

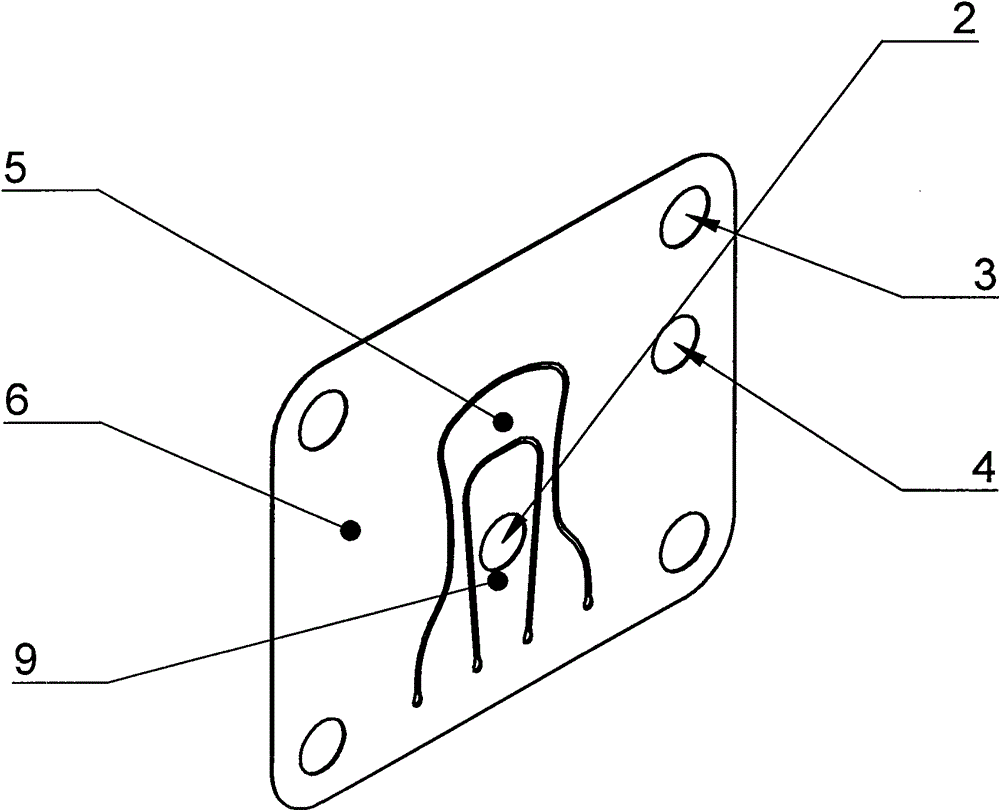

[0010] Such as figure 2 and image 3 As shown, the structure of the suction valve for refrigeration compressors of the present invention includes a valve body 6, an outer reed 5, an exhaust hole 2, a mounting hole 3, an orifice 4 and an inner reed 9, and the outer reed 5 adopts a double The arm reed structure has the function of sealing and bending movement. The maximum width dimension of the sealing area is D, the height dimension is H, and the dimension D is larger than the dimension H; the minimum width dimension of the bending area is d, and the minimum dimensions of the left and right arms are K1 and K2 respectively. Air vent 2 is arranged on inner reed 9, and inner reed 9 does not have the function of sealing and bending movement. When the dimension d needs to be increased, as long as the minimum dimensions K1 and K2 of the left and right arms are controlled, the energy consumption of the bending movement of the outer reed 5 will not increase. Therefore, when the dim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com