Temperature sensor structure of microwave oven

A technology of temperature sensor and microwave oven, applied in the field of microwave oven, can solve the problem that the positioning accuracy of the sensor probe cannot be accurately guaranteed, increase the overall production cost of the microwave oven, affect the accurate and normal operation of the microwave oven, etc. offset effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

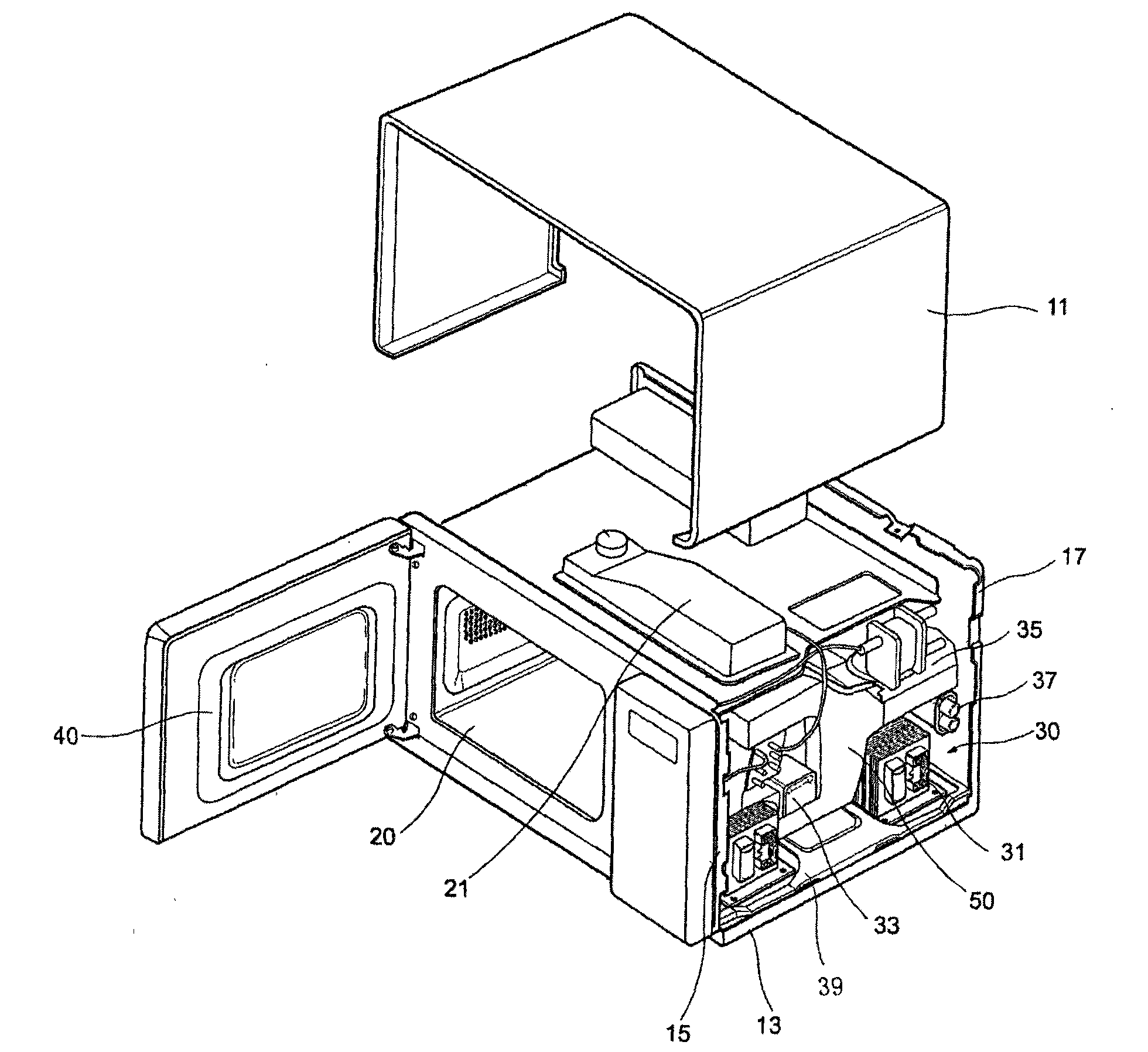

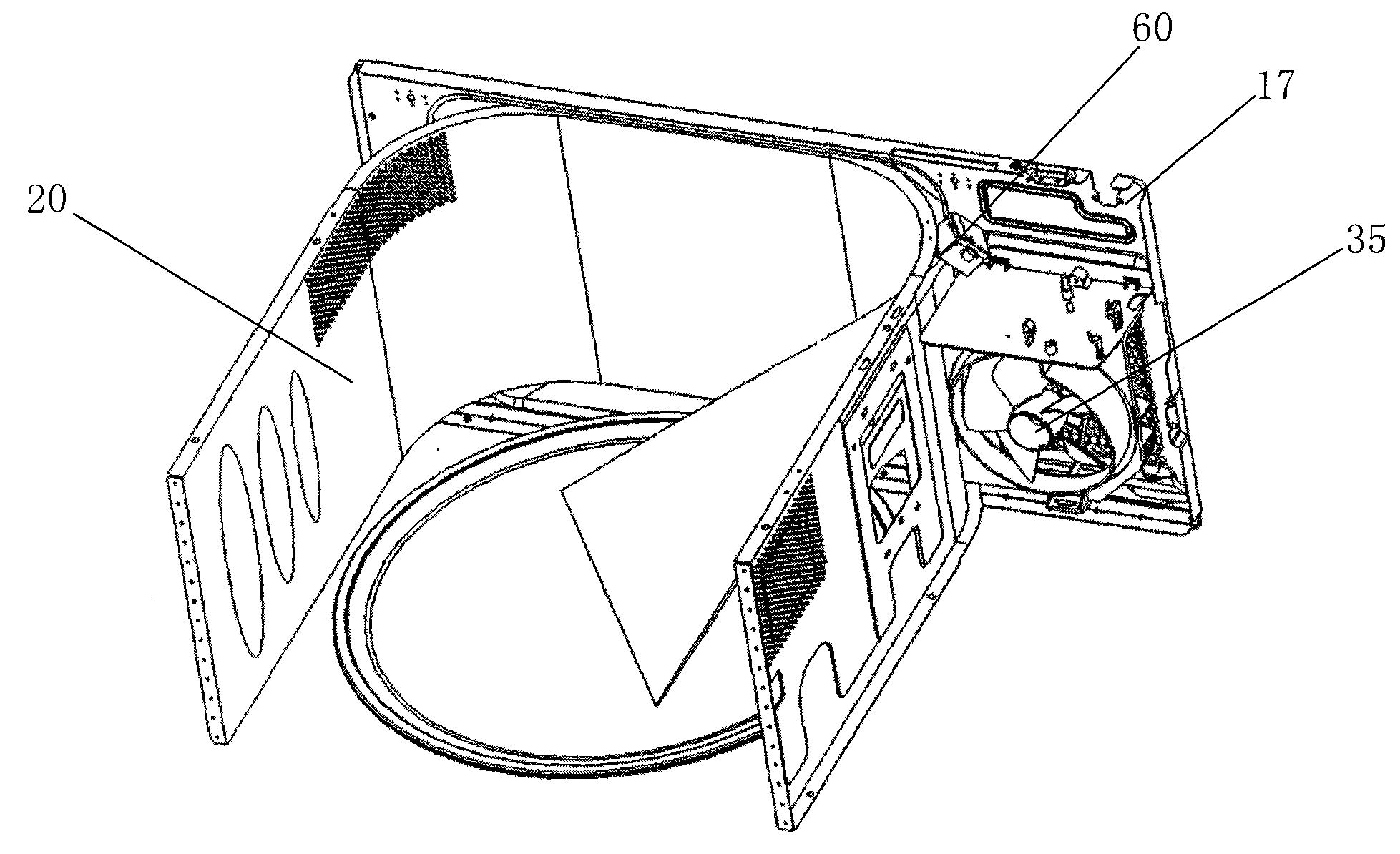

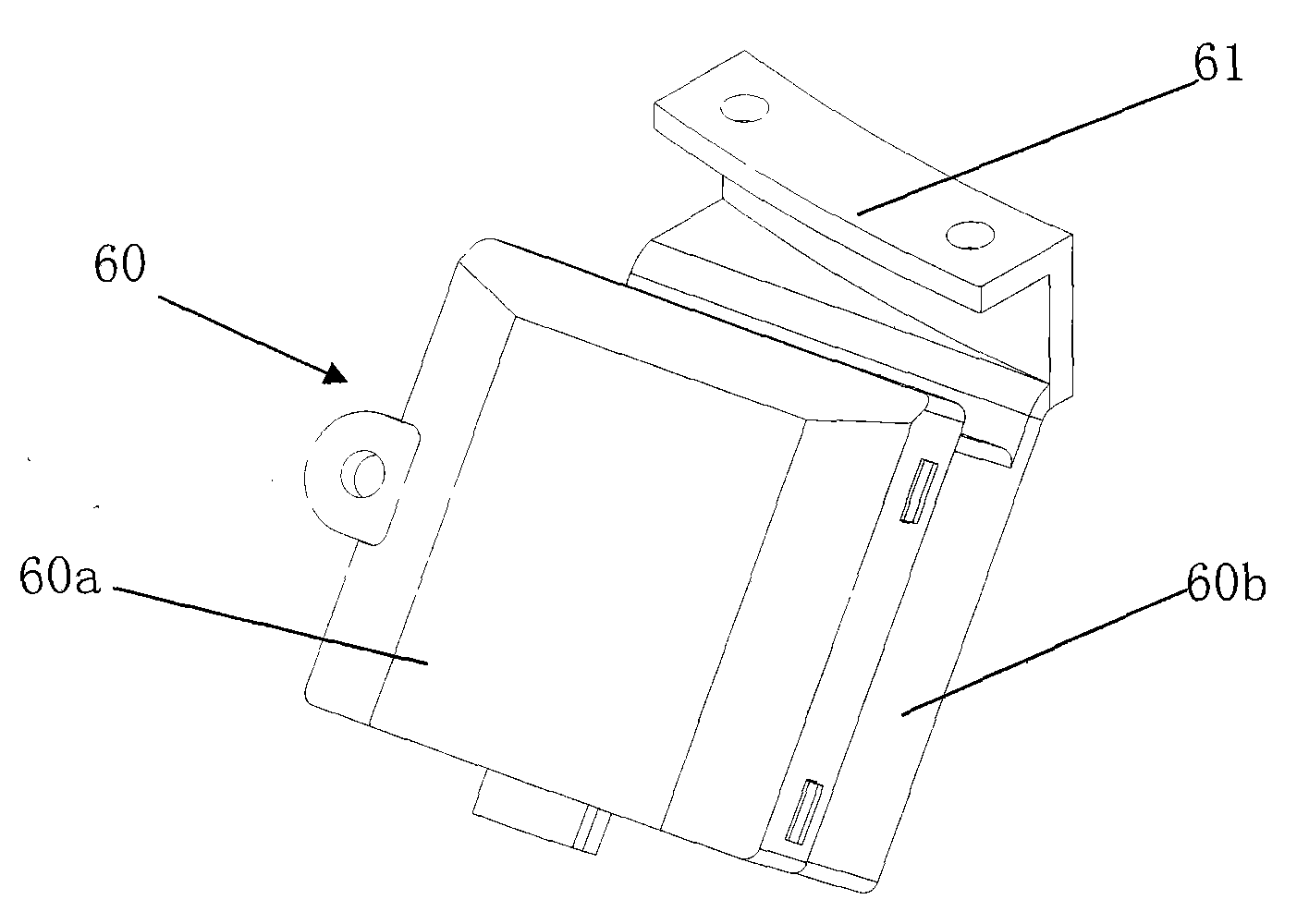

[0028] The present invention is described in detail below with reference to accompanying drawing and embodiment:

[0029] Figure 4 is a schematic diagram of the temperature sensor structure of the microwave oven of the present invention; Figure 5 It is a structural schematic diagram of the lower cover of the housing in the temperature sensor structure of the microwave oven of the present invention; Image 6 It is a structural schematic diagram of the shell upper cover in the temperature sensor structure of the microwave oven of the present invention.

[0030] like Figure 4 to Figure 6 As shown, the temperature sensor structure of the microwave oven of the present invention includes: a sensor probe, which is arranged outside the oven cavity of the microwave oven, and receives the infrared signal sent by the food in the oven cavity through the observation hole formed on the oven cavity and measures the temperature of the food. The temperature signal is converted into an el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com