Method for reducing discharge capacity of cobble coal of intermediate-speed coal mill

A coal mill and pebble coal technology, applied in grain processing, etc., can solve the problems of coal mill fire hazard, wear, replacement or repair of the blade end of the air inlet, etc., to reduce the discharge of pebble coal and reduce the ventilation area , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

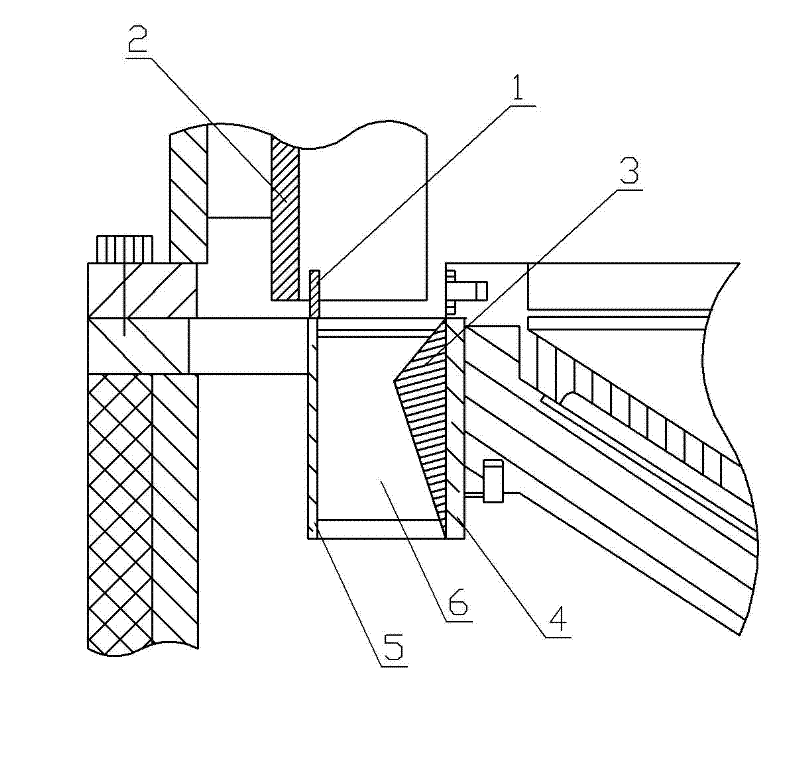

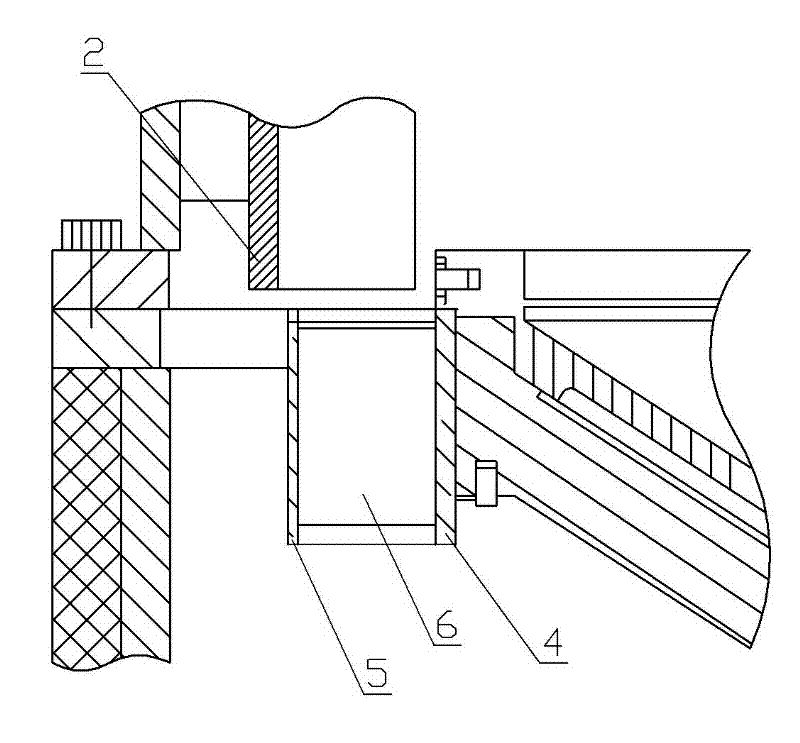

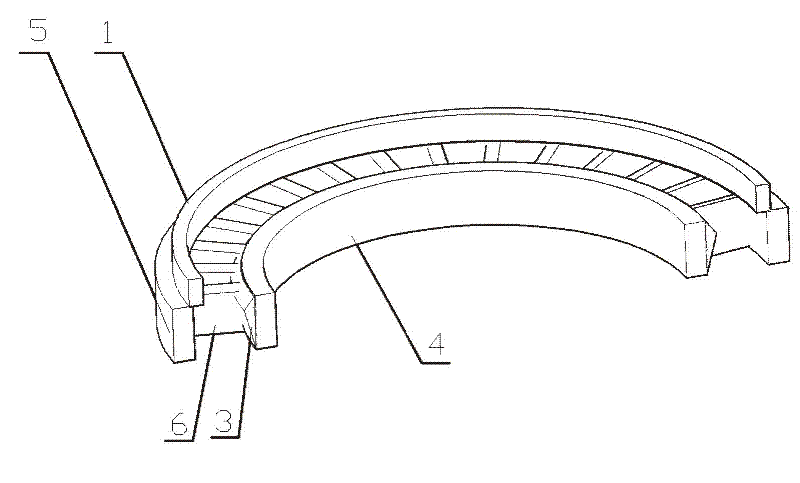

[0022] Such as figure 1 , 3 In the medium-speed coal mill shown, the high-speed rotating airflow carries the ground coal powder through the air ring and blows it to the separator. The coal powder that meets the particle size requirement passes through the separator and is sent to the boiler through the powder pipe, but does not reach the particle size. The required pulverized coal will fall back into the pulverizer for further grinding. A vertical guide ring 1 is installed at the air ring inside the coal mill. The guide ring is a continuous body without holes. A separator 2 is arranged above the air ring of the coal mill. The bottom of the guide ring is connected to On the end surface of the upper part of the air ring, the top surface of the guide ring is higher than the bottom surface of the separator 2, and the guide ring is used to ensure that the direction of the high-speed rotating airflow at the air ring is vertical upward, and is not affected by the high-speed flow fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com