Polyanion composite material for reducing benzo (a) pyrene contained in cigarette smoke and preparation method

A polyanion and composite material technology, which is applied in the fields of tobacco, tobacco processing, food science, etc., can solve the problems of increasing the content of harmful components, complex components, and influence on the taste of smoke, and achieves simple and easy operation, mild and controllable conditions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

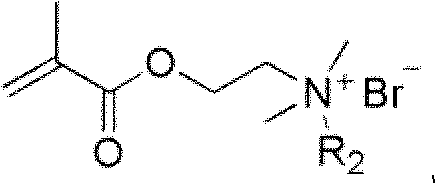

[0051] Add 10.1 grams of dimethylaminoethyl methacrylate into a round-bottomed flask containing 8.0 milliliters of benzyl bromide (or one of bromoethane, bromobutane, or hexadecane bromide), and add 20.0 milliliters of acetone, at 30 Reaction at ℃ for 12 hours to prepare quaternary ammonium salt type polymerizable monomer dimethylbenzylmethacryloyloxyethylammonium bromide (or dimethylethylmethacryloyloxyethylammonium bromide, dimethyl One of butyl methacryloyl oxyethyl ammonium bromide and dimethyl hexadecyl methacryloyl oxyethyl ammonium bromide). The structures of the prepared quaternary ammonium salt type polymerizable monomers were all proved by infrared spectrum characterization analysis.

[0052] Among them, the infrared spectrum characteristic signal peaks of dimethyl benzyl methacryloxyethyl ammonium bromide: 3004, 1722, 1634, 959cm -1 ; The infrared spectrum characteristic signal peak of dimethyl ethyl methacryloyloxyethyl ammonium bromide: 1720, 1634, 959cm -1 ; Th...

Embodiment 2

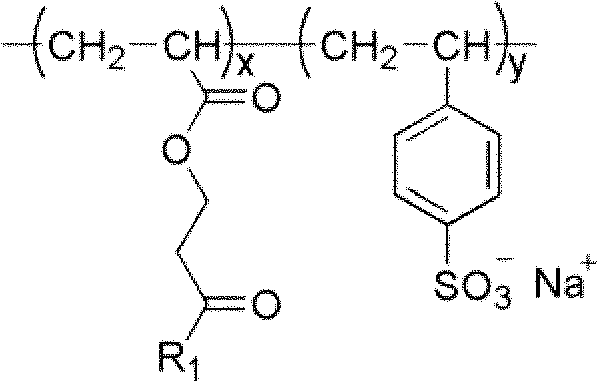

[0055] Four kinds of quaternary ammonium salt type polymerizable monomers (0.02mol) prepared in Example 1 were added respectively in the polymerization tube containing distilled water, and an appropriate amount of potassium persulfate aqueous solution (mass percentage concentration was 1%) was added thereto, The four kinds of quaternary ammonium salt type polycations were respectively prepared by passing nitrogen protection and reacting at 70° C. for 6 hours. The structure of the prepared polycation is proved by characterization analysis such as infrared spectrum.

[0056] Among them, the infrared spectrum characteristic signal peaks of polydimethylbenzylmethacryloxyethylammonium bromide: 3385, 1727, 1149cm -1 ; The infrared spectrum characteristic signal peak of polydimethylethylmethacryloxyethylammonium bromide: 3373, 1728, 1456cm -1 ; The infrared spectrum characteristic signal peak of polydimethylbutylmethacryloxyethyl ammonium bromide: 3447,1728,1467cm -1 ; The infrared...

Embodiment 3

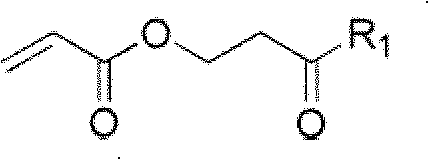

[0059] Add 30.0 ml of acrylic acid, 130.0 ml of vinyl acetate, 3.2 g of mercury acetate, a small amount of copper acetate and 0.3 ml of concentrated sulfuric acid into a three-necked flask, stir at 50°C, and react for 3 hours to prepare acryloxy vinyl propionate . The structure of the prepared product was determined by characterization analysis such as infrared spectroscopy.

[0060] After infrared spectrum characterization analysis, the prepared product has infrared spectrum characteristic signal peaks of acryloyloxy vinyl propionate: 3100, 1759, 1731, 1647, 1409, 1058, 985cm -1 , indicating the successful preparation of vinyl acryloxypropionate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com