Sand-dust removing device

A technology for removing devices and dust, applied in track cleaning, cleaning methods, construction, etc., can solve the problems of affecting the service life of rails and train wheels, aggravating the wear of rails and train wheels, and being unable to promote the use of railway systems, so as to protect the environment. and equipment, reducing the labor intensity of work, and the effect of high power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is further described as follows in conjunction with accompanying drawing and embodiment:

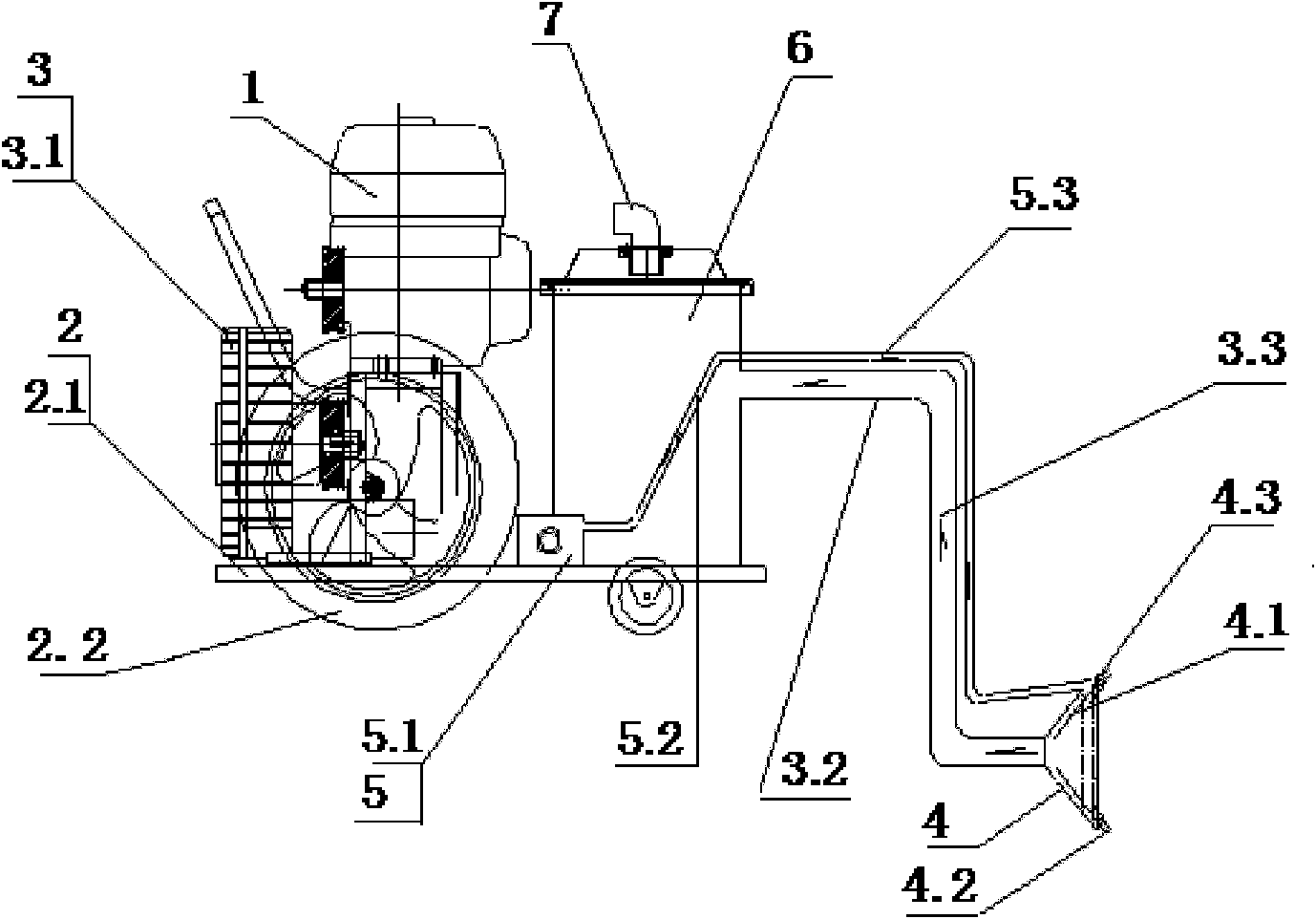

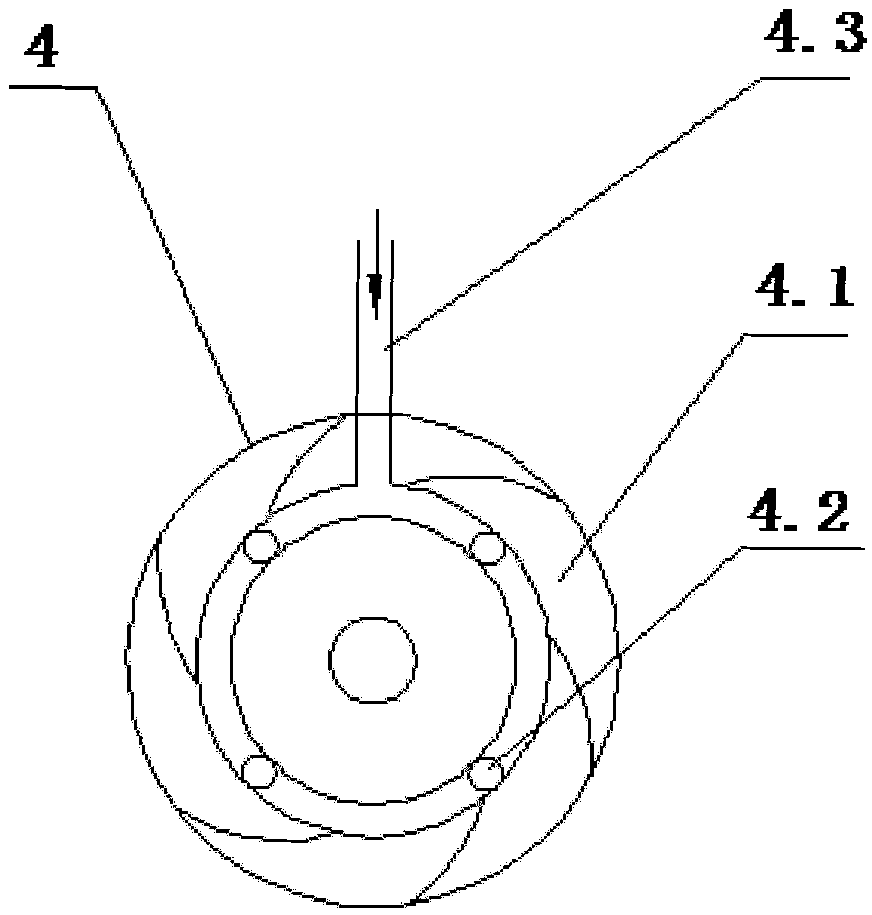

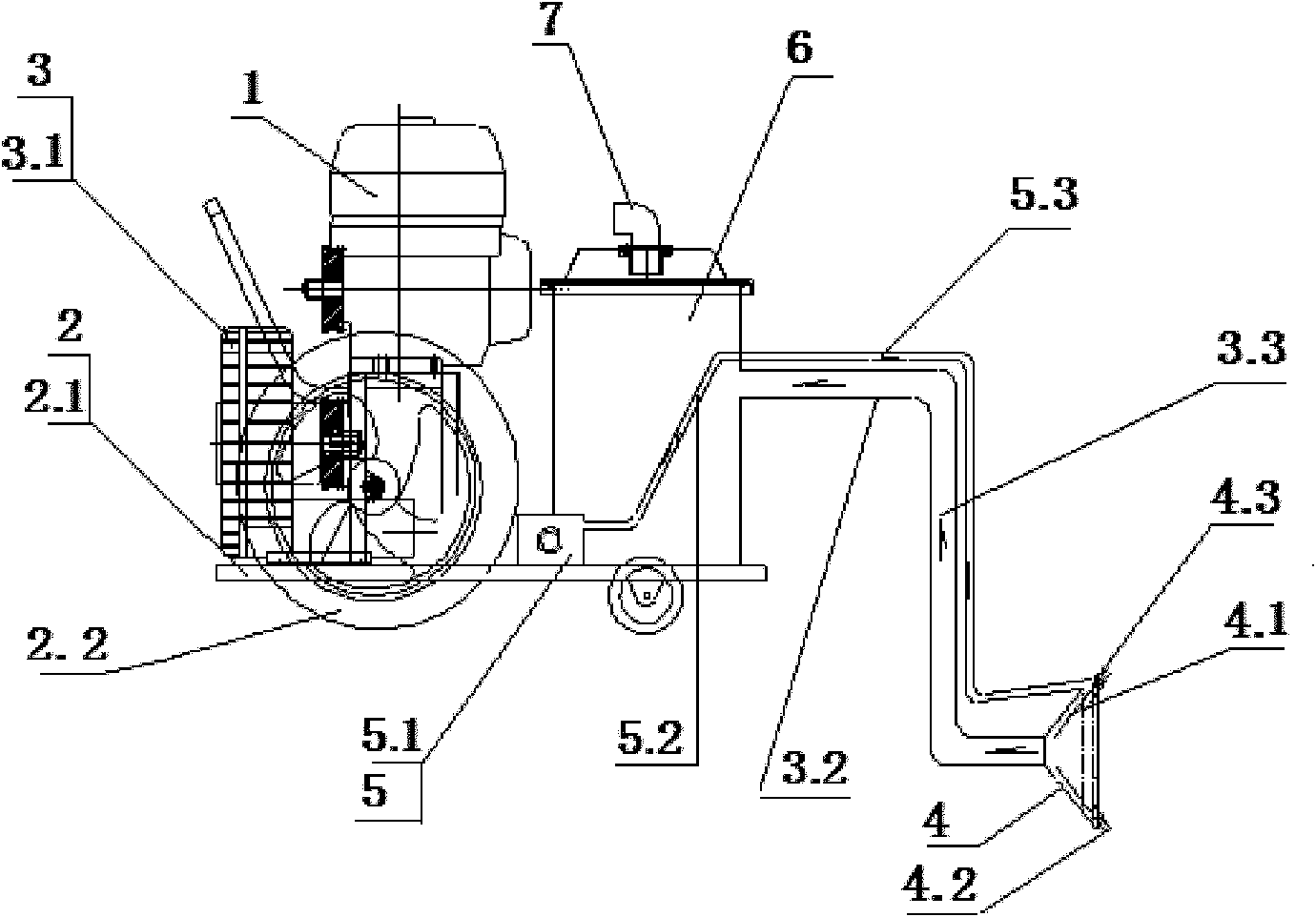

[0021] Such as figure 1 figure 2 Shown, a kind of dust removal device, it has an engine 1 that is installed on the running gear 2, also has dust suction system 3 and air pressurization system 5, and dust treatment device 6; Described dust suction system 3 There is a vacuum pump 3.1, and the suction head 4 connected with the vacuum pump 3.1 through the dust suction pipe 3.2; the air booster system 5 has an air booster pump 5.1, and the air booster pump 5.1 passes through the booster air tube 5.2 and The pressurized air nozzle 4.2 communicates with the suction head 4 . The suction head 4 is trumpet-shaped, the big mouth is the dust suction port, and the small mouth is connected with the dust suction pipe 3.2; there are several dust gas inlet air ducts 4.1 connected with the dust suction pipe 3.2 on the inner wall of the suction head 4, and this embodiment is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com