Wire twister

A technology of twister and twister, which is applied in auxiliary devices for rope making, textiles and papermaking, electrical components, etc. It can solve the problems of cable or rope deformation or twisting, increase cable resistance, etc., and achieve simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

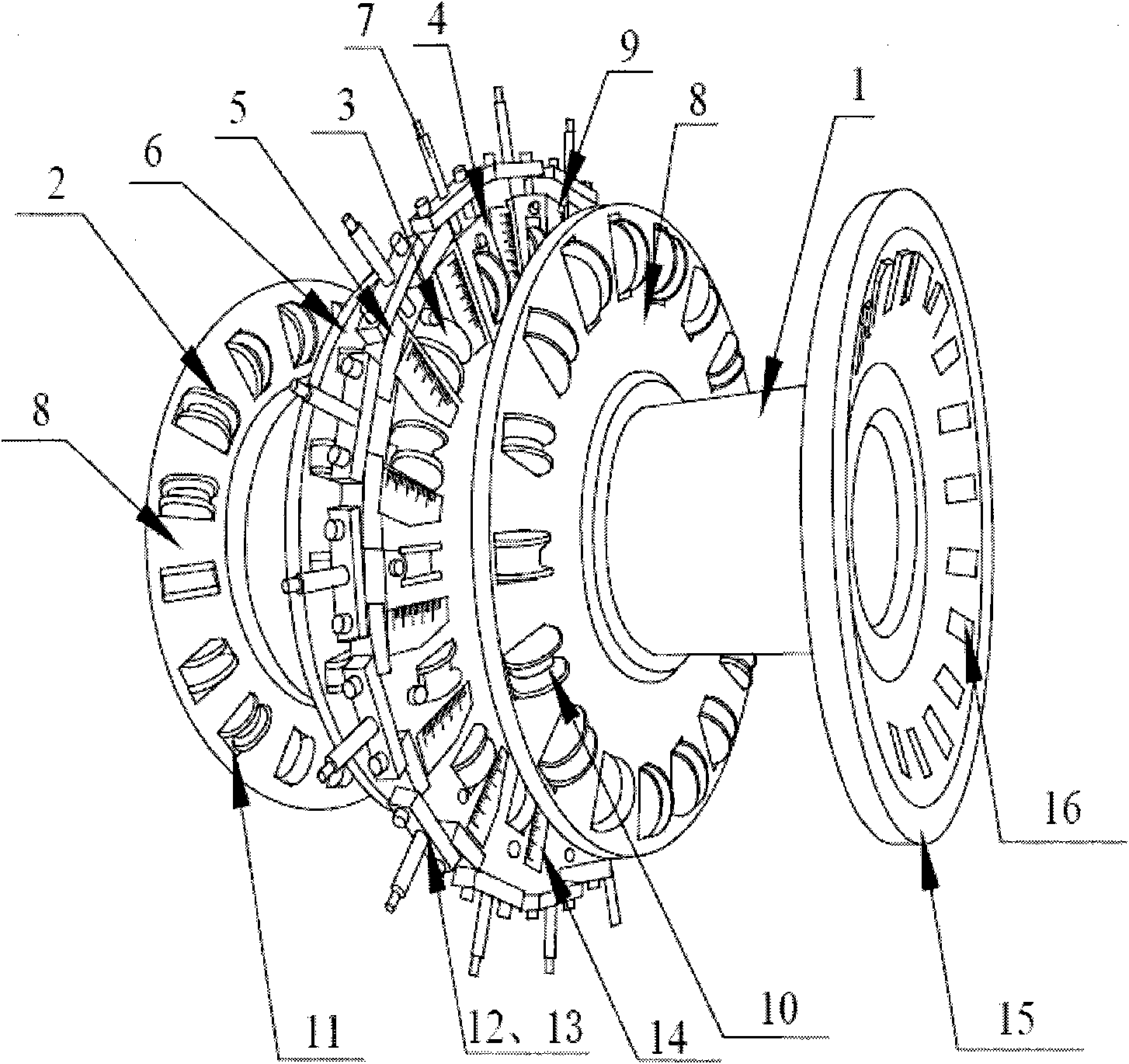

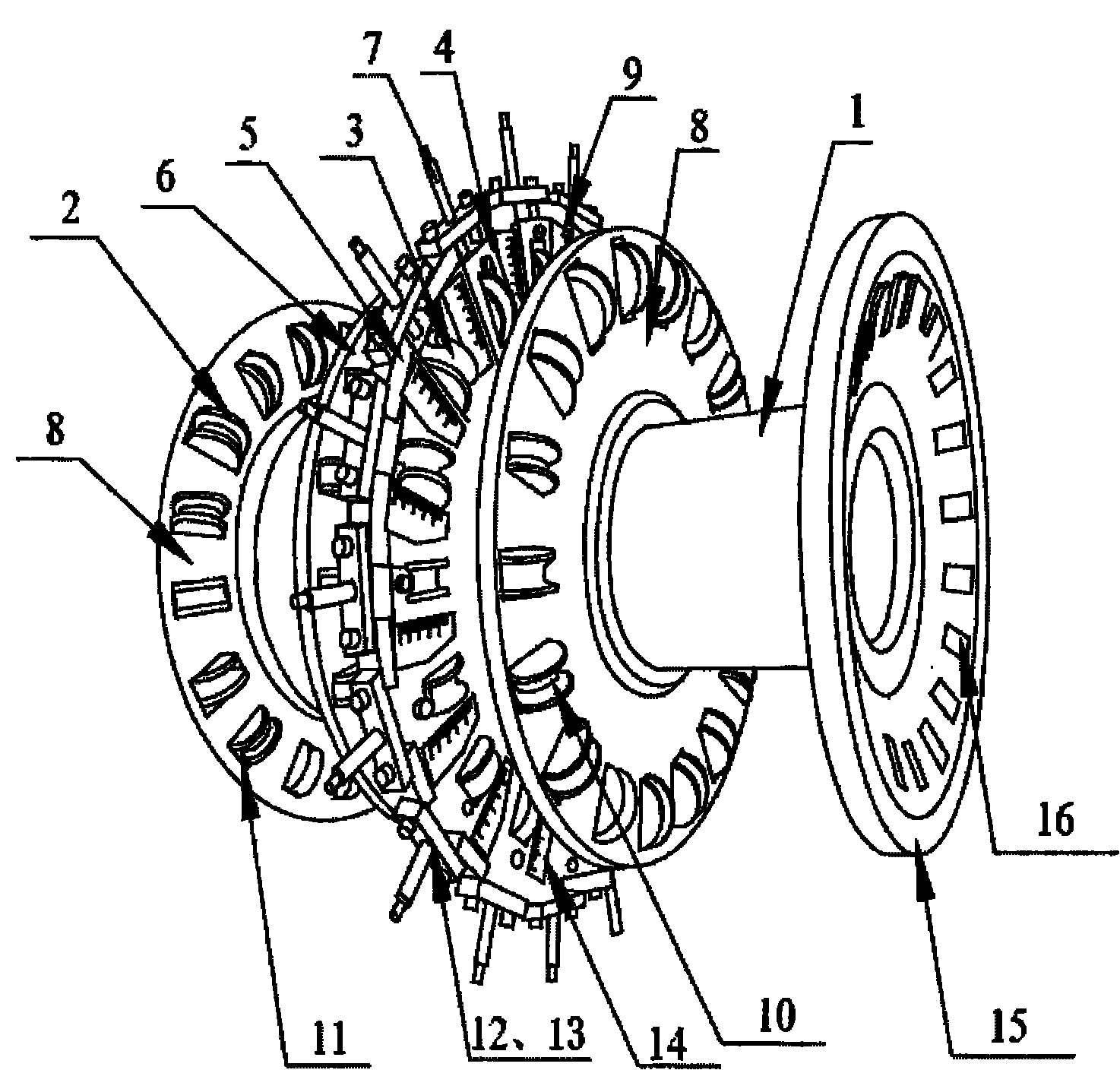

[0020] Such as figure 1 As shown, the present invention is a kind of wire twister, and this wire twister comprises 4 winch coils that are installed on the same hollow shaft 1, is provided with several wire pulleys and grooves on the concentric circumference of each strand coils hole, the guide wheel includes a fixed guide wheel 2 and a movable guide wheel 3, the fixed guide wheel 2 is connected with the winch reel through the roller on the guide wheel, and the movable guide wheel 3 passes through Described roller is connected on the slide block 4, and described slide block 4 cooperates with slide rail block 5, and one side of described slide rail block 5 is fixed on the connection plate 6, and described connection plate 6 is fixed on the hollow On the shaft 1; wherein, the axis of the roller is perpendicular to the radial line of the winch reel; an adjustment rod 7 is arranged at the end of the slider 4, and the adjustment rod 7 is arranged on the slider The adjusting parts o...

Embodiment 2

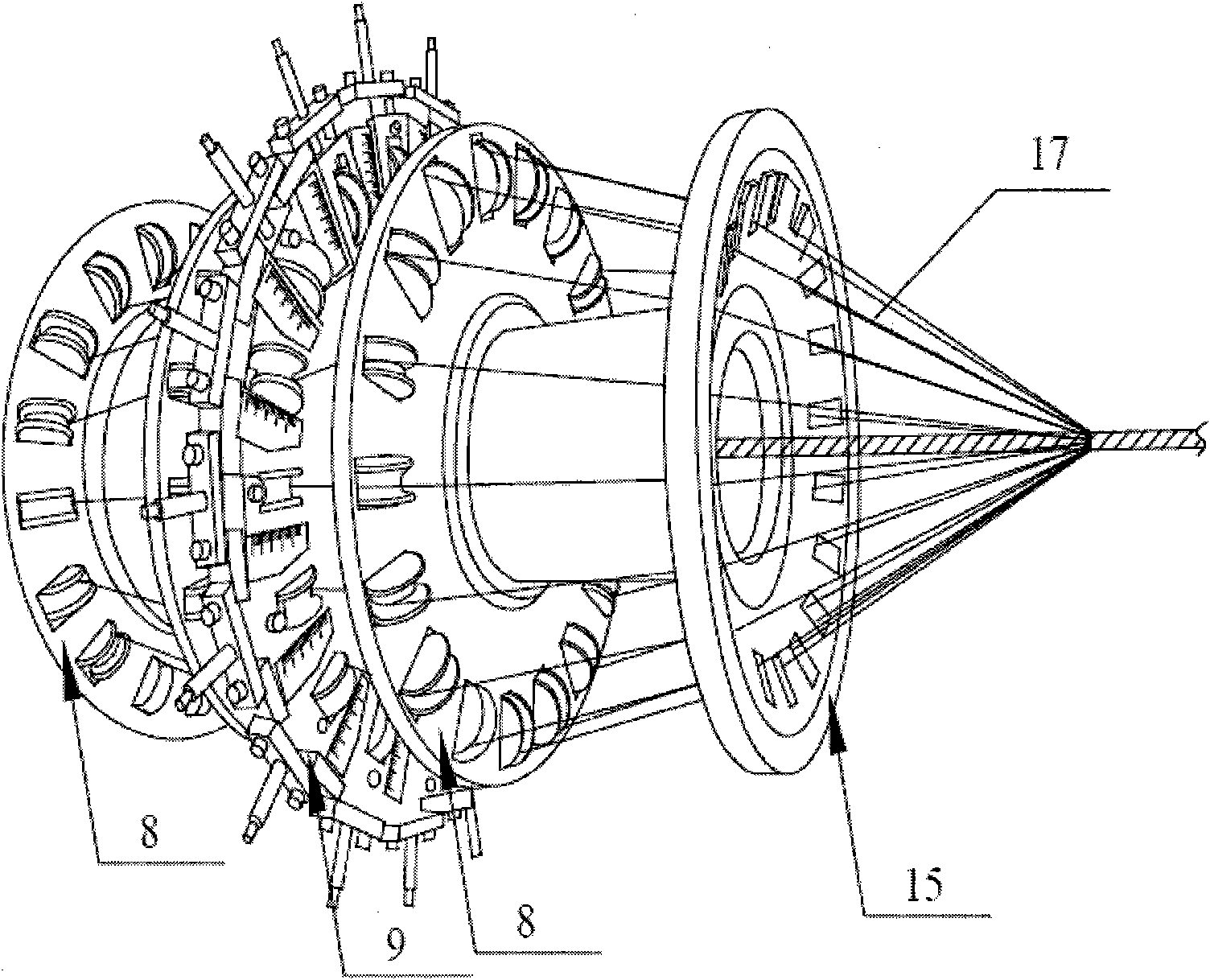

[0022] On the basis of embodiment 1, the preferred embodiment of the present invention is, because described winch includes fixed winch 8, movable winch 9 and wire passing type winch 15, described Several fixed guide wheels 2 and several movable guide wheels 3 are respectively arranged on the fixed winch reel 8 and the movable winch reel 9, and the movable winch reel 9 includes the connection disc 6, the fixed The other structures of the slide rail block 5 on the connecting plate 6 and the slide block 4 cooperating with the slide rail block 5 are exactly the same as those of the first embodiment.

Embodiment 3

[0024] On the basis of Embodiment 2, the preferred embodiment of the present invention also includes that an annular groove 10 is set on the surface of the fixed guide wheel 2 and the movable guide wheel 3, and the radial section of the annular groove 10 V-shaped, the annular groove 10 can facilitate the passage of cables, and the rest of the structure is exactly the same as that of Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com