Conductive connection for track-riding patient hoists

一种轨道、患者的技术,应用在提升舱领域,能够解决滑车电力丢失等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

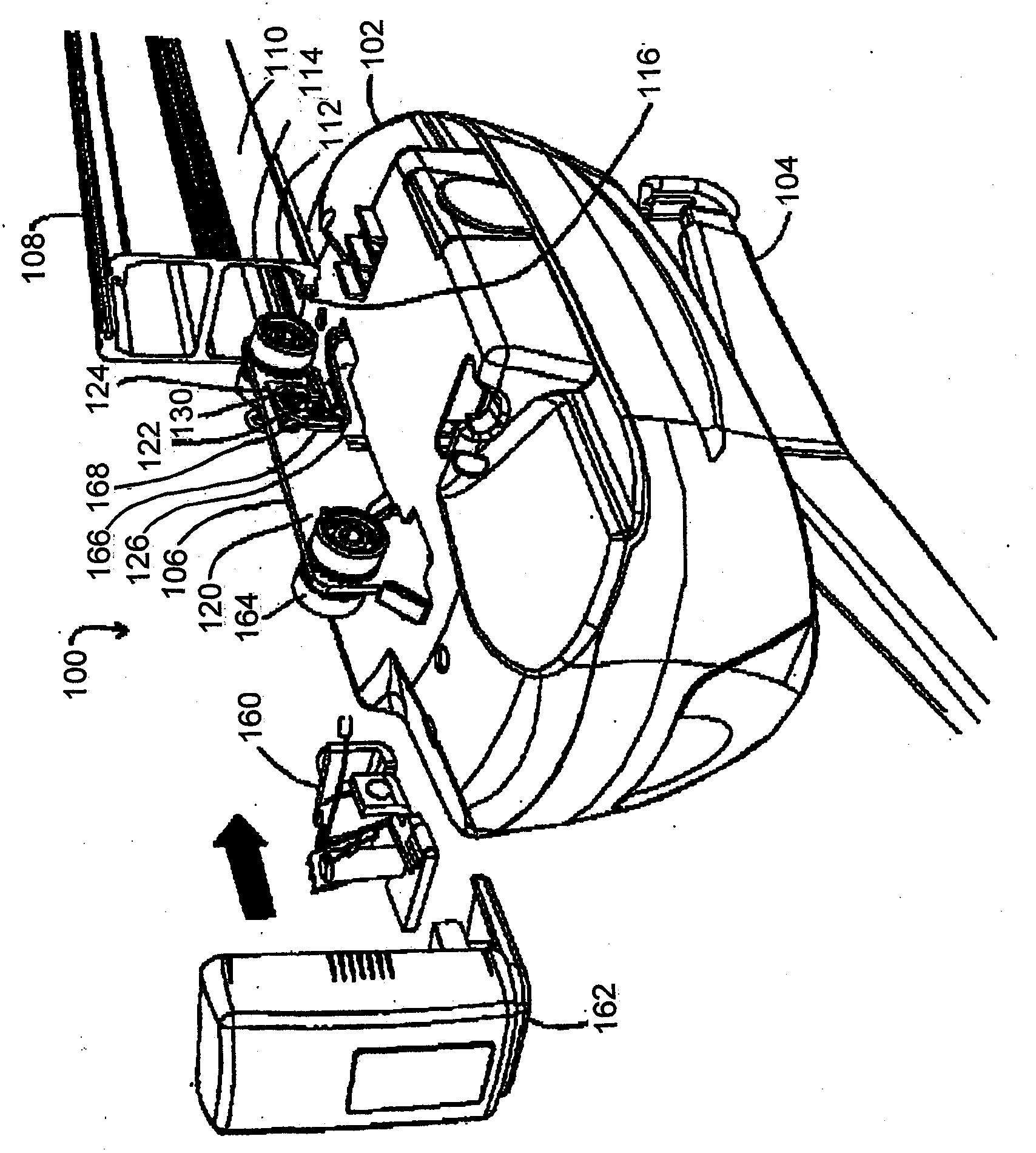

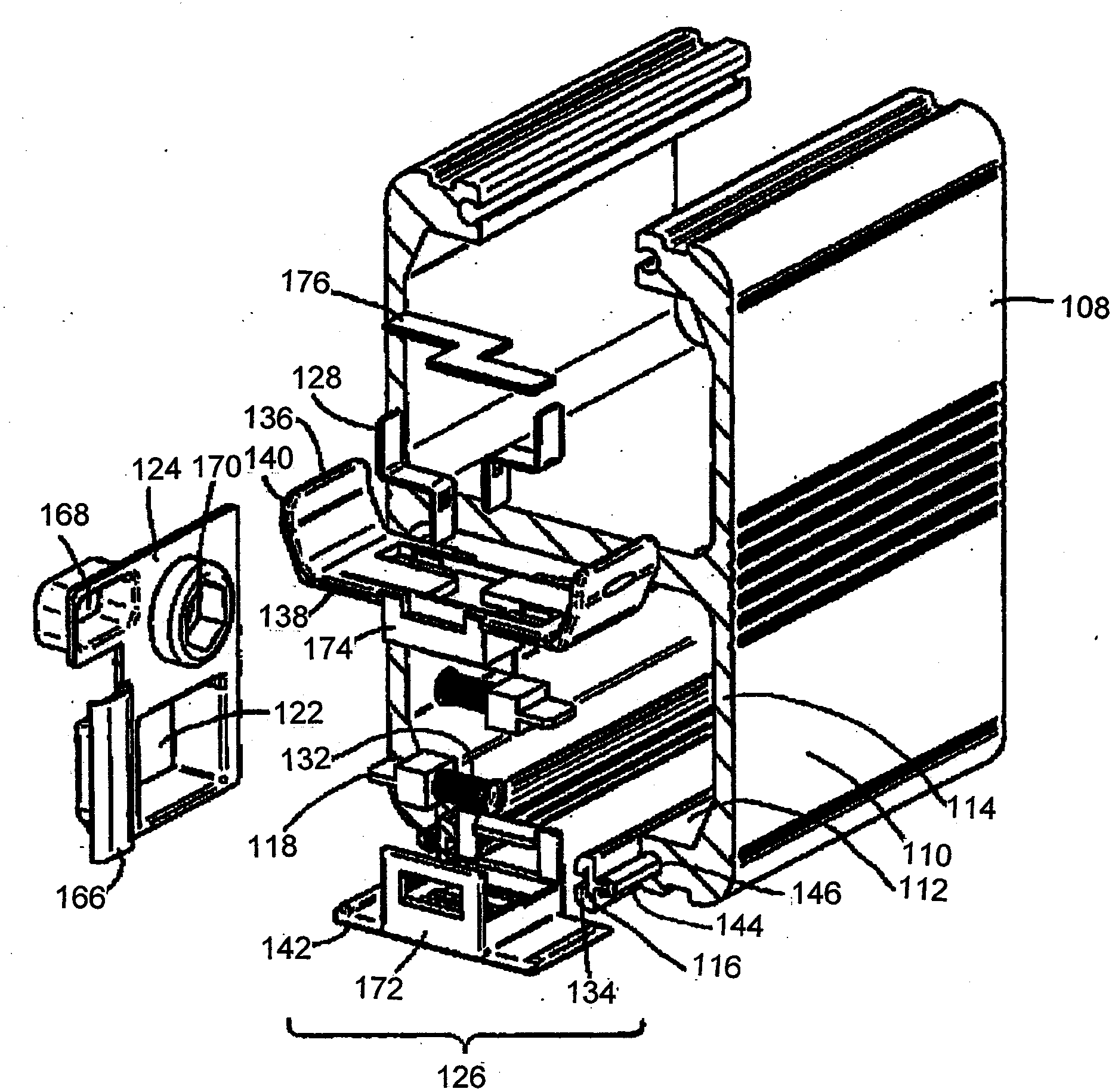

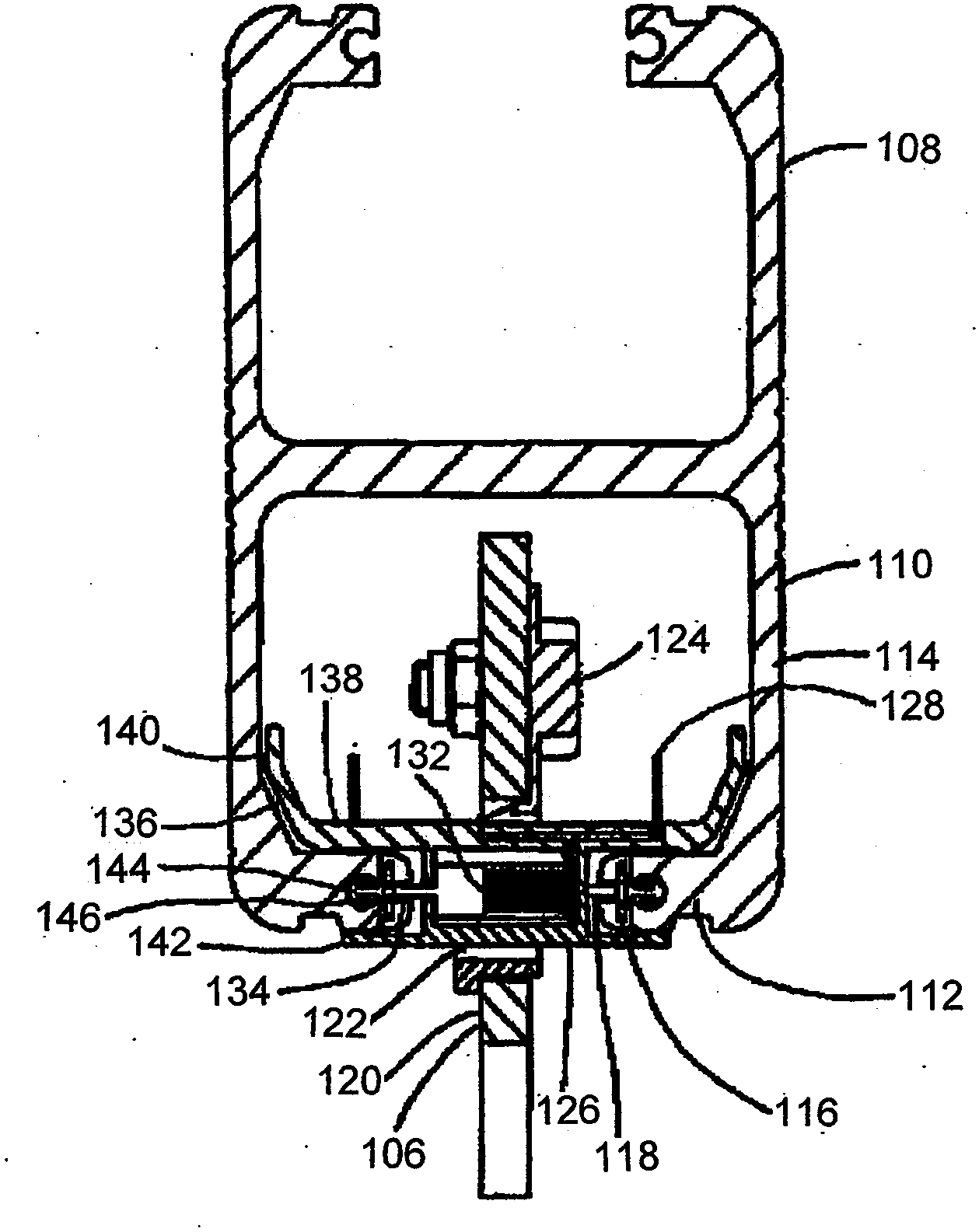

[0016] Elaborating on the above discussion, the riser 102 and track 108 illustrated in all drawings were developed by BHM Medical Inc. (Magog, Quebec, Canada), which offers several different track and riser configurations. (Magog, QC, Canada)) was adapted from the KWIK track and lift cabin system. The example rails 108 illustrated in all figures are configured in a manner similar to a pair of C-channels joined with their mouths facing in opposite directions, as best seen in image 3 middle. Usefully, some versions of the KWIKtrack track have included connection slots 146 that can be used to receive the connection tongues 144 of the track conductors 116, as previously described. Accordingly, the track 108 is easily constructed by installing only the track conductor 116 therein. Once the track conductor 116 is installed in the track 108, it can be moved by placing the lift cabin trolley 106 on the track side 110 (e.g. figure 1 As illustrated in ) to install the hoist cabin tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com