Segmented rapid heating of fluid

A technology for heating fluids and fluids, applied in heating methods, water heaters, feed water heaters, etc., can solve problems affecting electromagnetic sensitive equipment, difficult to suppress or shield, dissatisfaction with radio frequency noise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

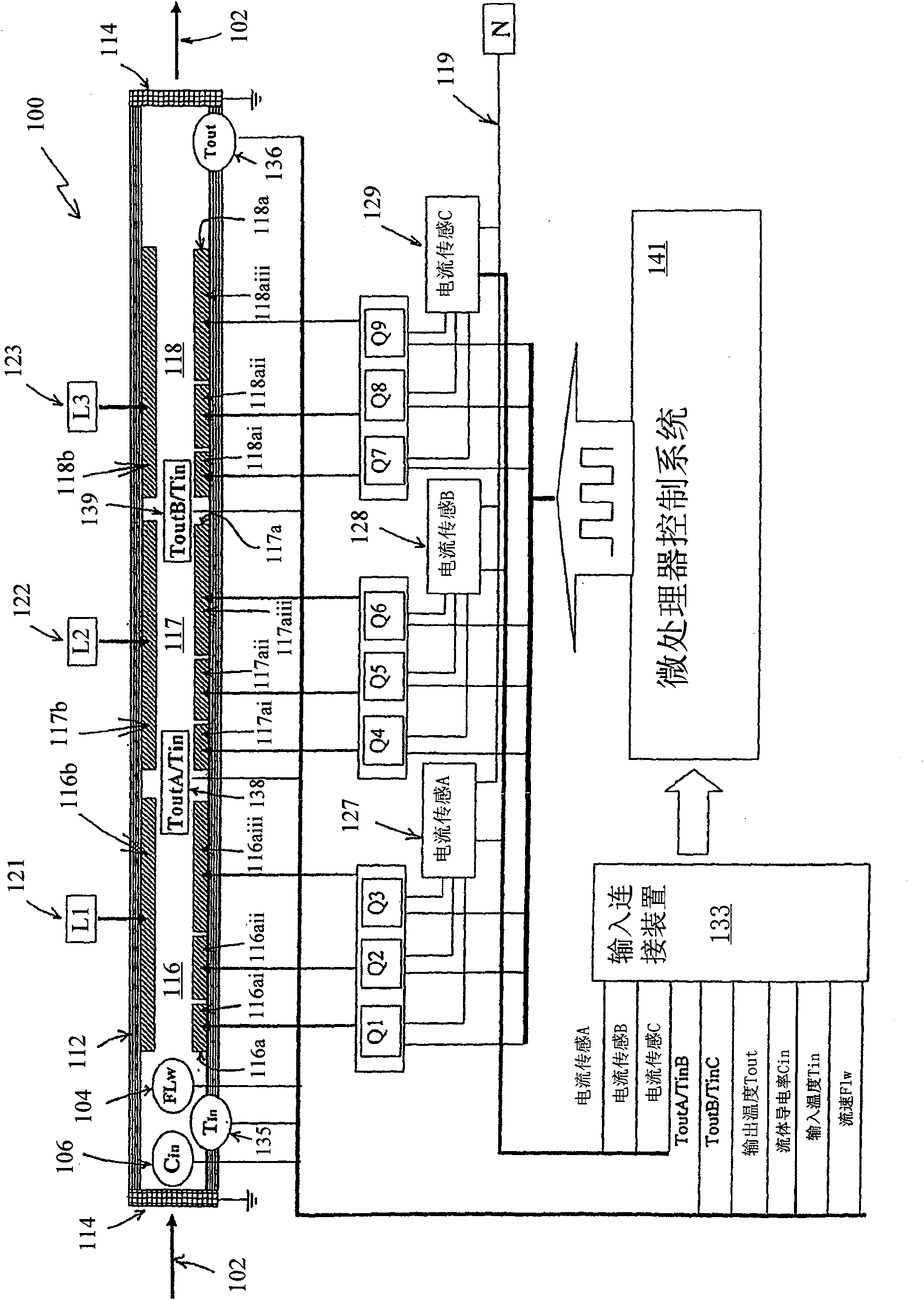

[0073] figure 1 It is a schematic block diagram of a fluid heating system 100 according to an embodiment of the present invention, in which water flows through the main body 112. The main body 112 is preferably made of an electrically insulating material, such as synthetic plastic. However, the main body 112 may be connected to a conductive metal water pipe (for example, a copper pipe). Therefore, the import and export of the main body 11 include figure 1 The grounded mesh grid is shown, thereby electrically grounding any metal pipes connected to the device 100. The ground grid 114 is ideally connected to the conductive ground electrode of the electric device, and the heating system of this embodiment is installed in the electric device. When the ground mesh grid 114 draws current from the electrodes through the water flowing through the device 100, the ground leakage protection device in the control system and / or the circuit breaker will be turned on or the leakage current ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com