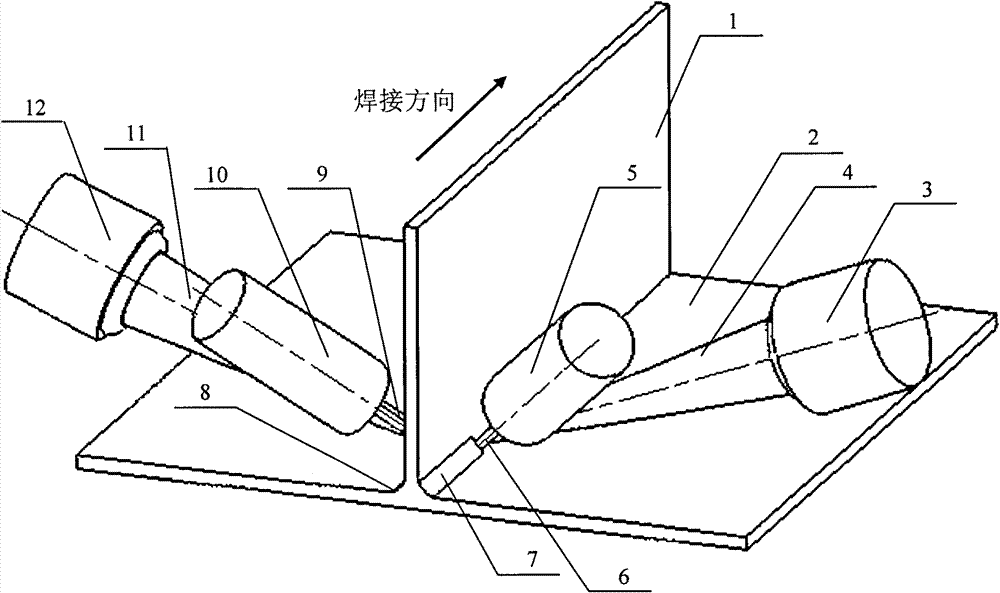

Non-splash, low-deformation, high-quality and high-efficiency welding method for T-shaped joint of aluminum alloy sheet

A low deformation, aluminum alloy technology, applied in welding equipment, laser welding equipment, metal processing equipment, etc., to achieve the effect of less weight gain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

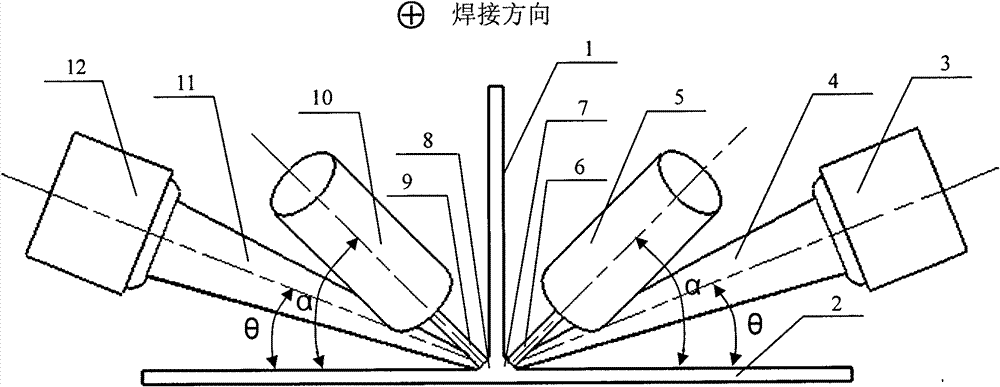

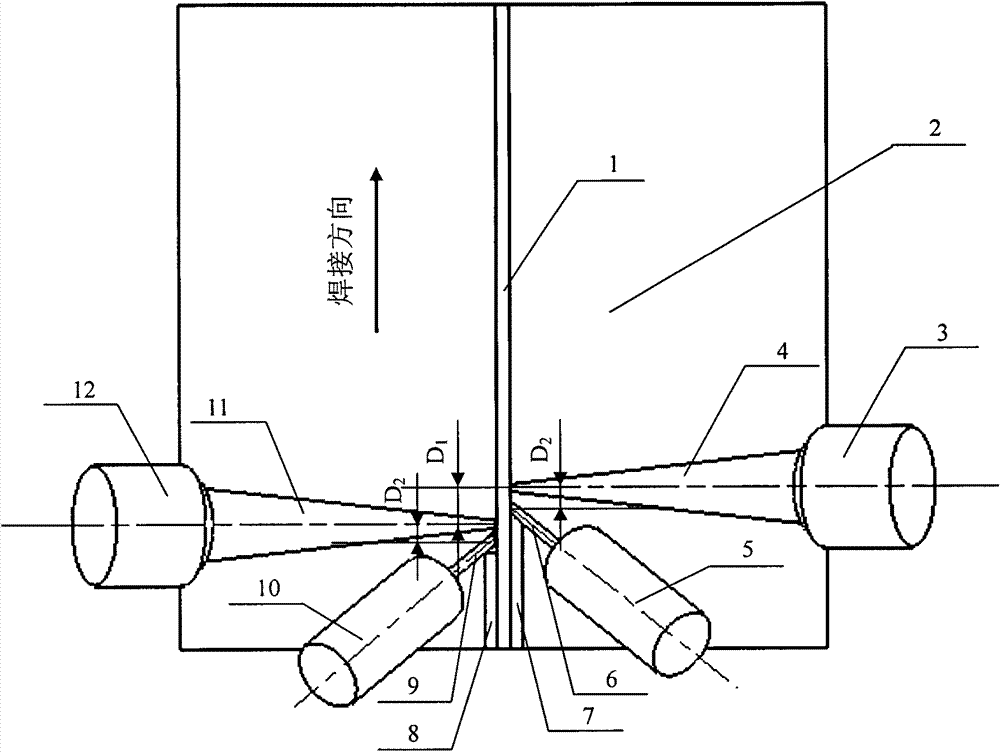

Method used

Image

Examples

Embodiment Construction

[0026] The laser used in the test is a Trudisk6002 disk laser with a maximum rated power of 6kW and an output laser wavelength of 1.03μm. Through the control of the optical splitting system, two channels of laser with the same power can be output at the same time; the arc power supply is TPS4000CMT digitized and precise waveform control produced by Fonius Company in Austria Short-circuit transition welding power supply and wire feeder; the test materials used are 5083 and 6061 aluminum alloy sheets with a thickness of 2mm, among which, the specification of the rib plate is 300mm×60mm, and the specification of the base plate is 300mm×100mm; the welding wire used is φ1.2mm in diameter ER5087 aluminum alloy welding wire; remove oil and oxide film on the surface of the welded aluminum alloy test plate before welding. During the test, precise waveforms are used to control arc and laser recombination, and the specific welding specification parameters are as follows:

[0027] 1) 5083...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com