Rubber plate for railway level crossings and rubber hold-down strip thereof

A technology of rubber beading and track boards, which is applied in the field of rubber beading and rubber beading filled between the rubber bead and the track, which can solve the problems of endangering the safety of motorcycle riders, unevenness, and slipping of motorcycle tires And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In order to have a further understanding of the characteristics of the present invention, now cooperate with relevant embodiments and drawings to describe in detail as follows:

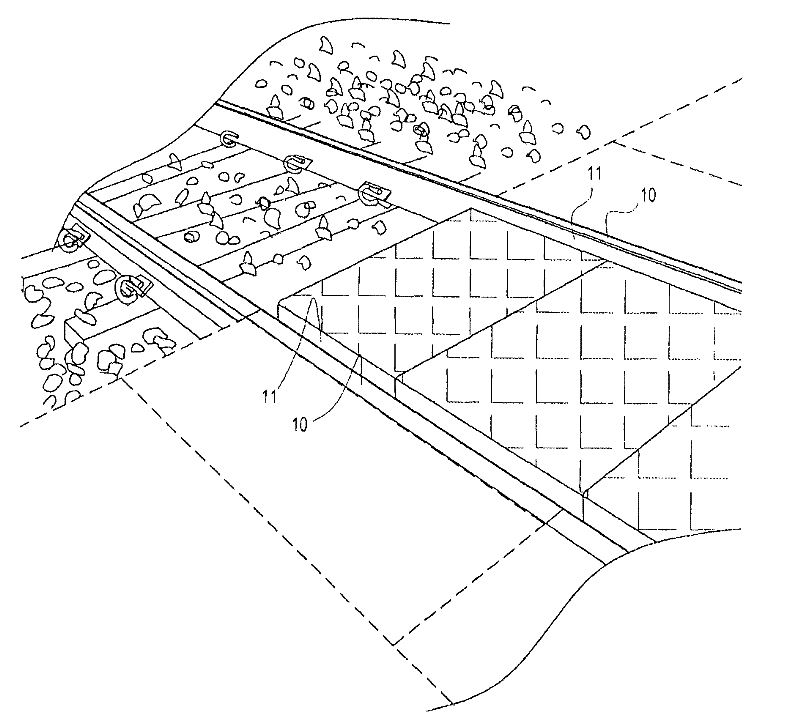

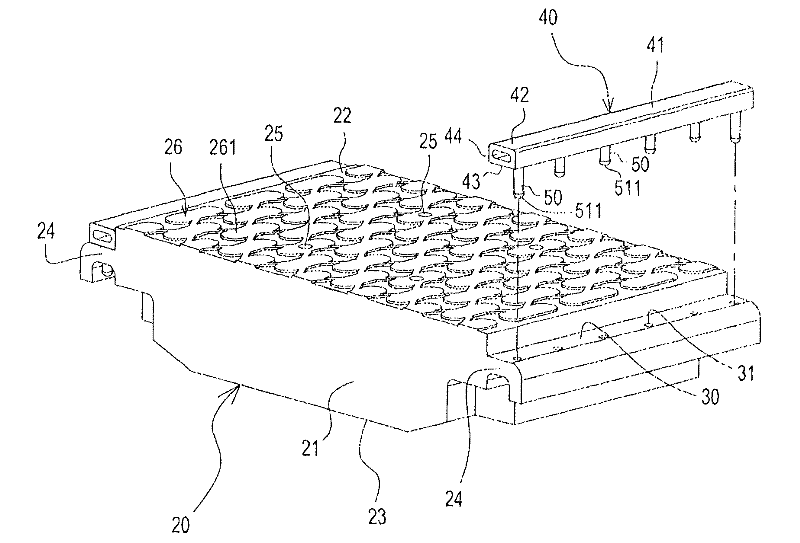

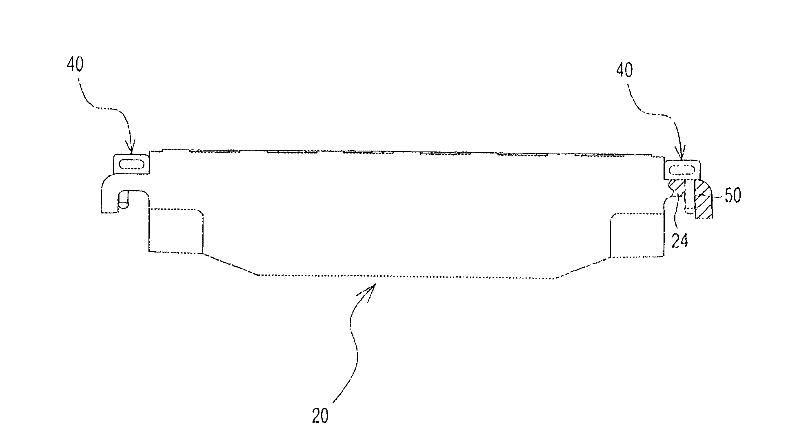

[0053] First please refer to figure 2 The three-dimensional exploded view of the rubber road plate and rubber bead embodiment of the present invention shown in the drawing, image 3 The schematic diagram of the combination of the embodiment of the rubber track plate and the rubber bead of the present invention is shown. The rubber track 20 includes: a track main body 21 and two grooves 30 on the outside. The main body 21 of the road plate has a top surface 22 and a bottom surface 23. The main body 21 of the road plate has a shoulder 24 corresponding to each outer side of the two rails A. The main body 21 of the road plate is also provided with at least one drainage piece 25, and the water drainage piece 25 can be a hole or groove structure and runs through the entire track plate main body 21....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com