Rotary percussion hammer

A technology of impact hammer and impact head, which is applied in drilling equipment, earthwork drilling, driving device for drilling in wellbore, etc., can solve the problems of affecting the working efficiency of impact hammer, weaken the impact force of impact hammer, etc. , Increase the impact force and avoid the effect of collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

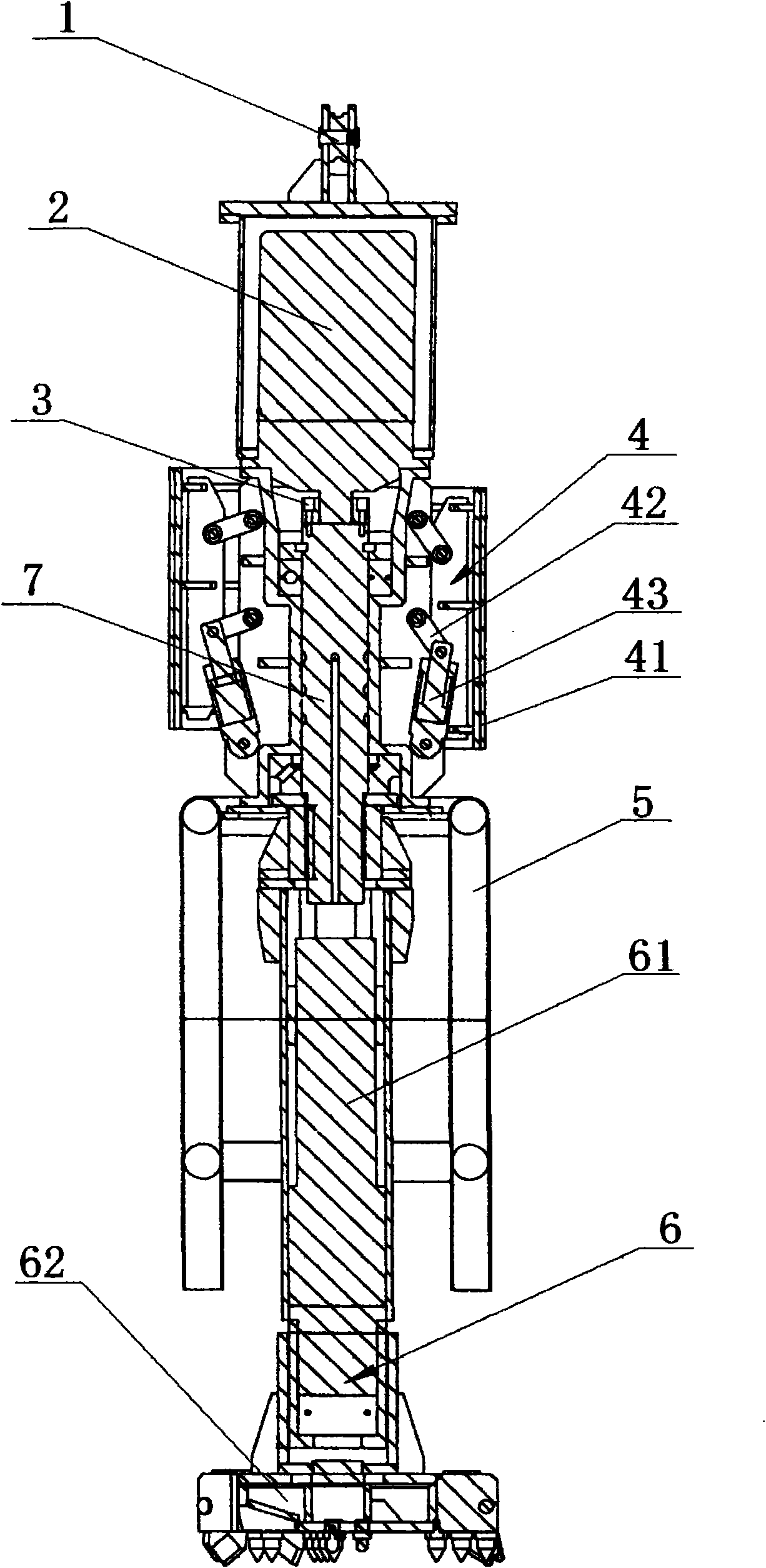

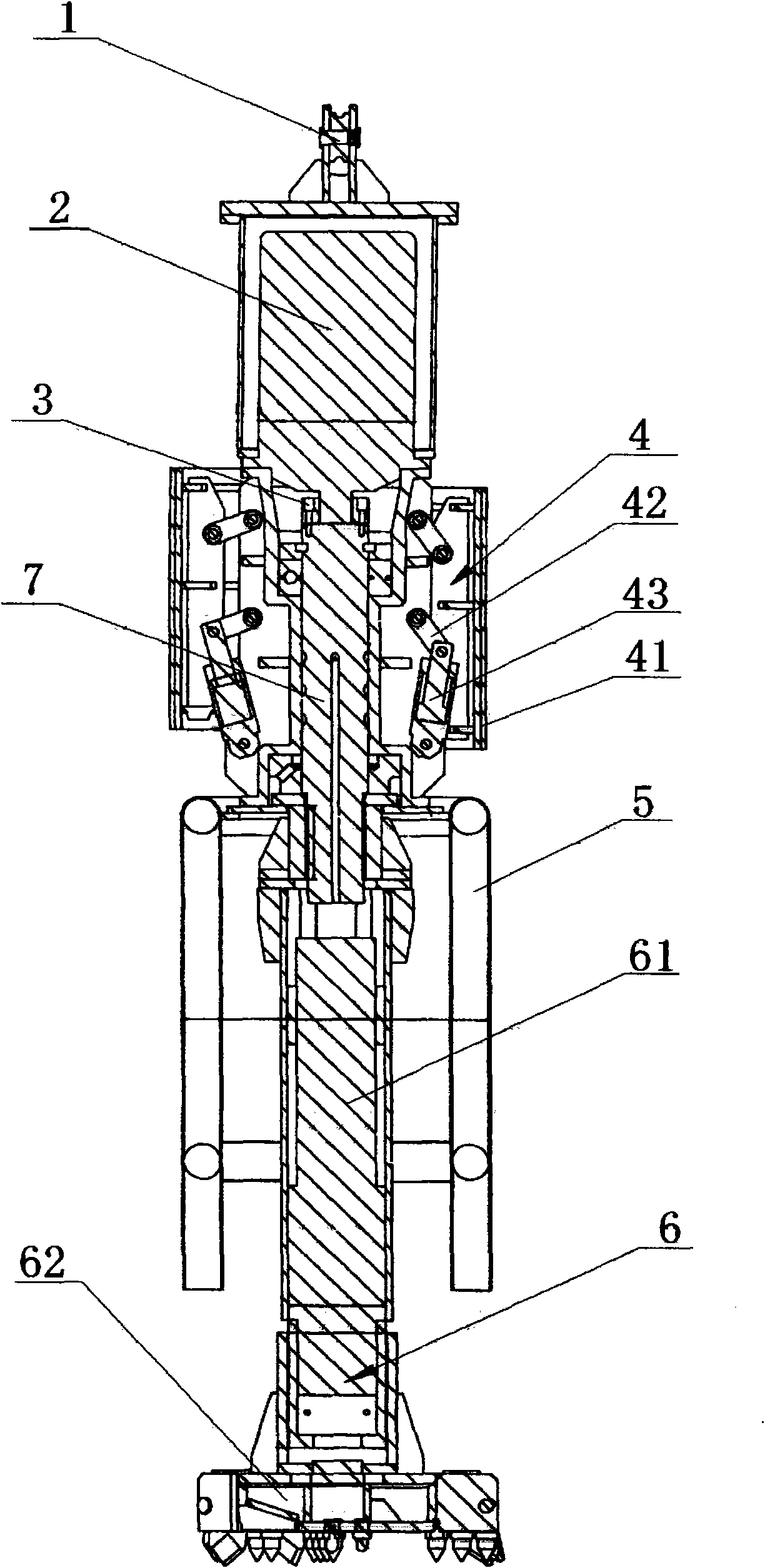

[0010] A rotary impact hammer of the present invention is composed of a spreader 1, a rotary power device 2, a connecting device 3, a mud suction pipe 5, an impact device 6, and a turning device 7. 1 Connect with the crane for construction work. The rotary power device 2 provides rotary power for a rotary impact hammer of the present invention. The impact device 6 provides downward impact power for a rotary impact hammer of the present invention. Since a rotary impact hammer of the present invention rotates continuously during operation, the rotary device 7 is required to provide an oil supply circuit for the impact device 6 and high-pressure gas for sand washing.

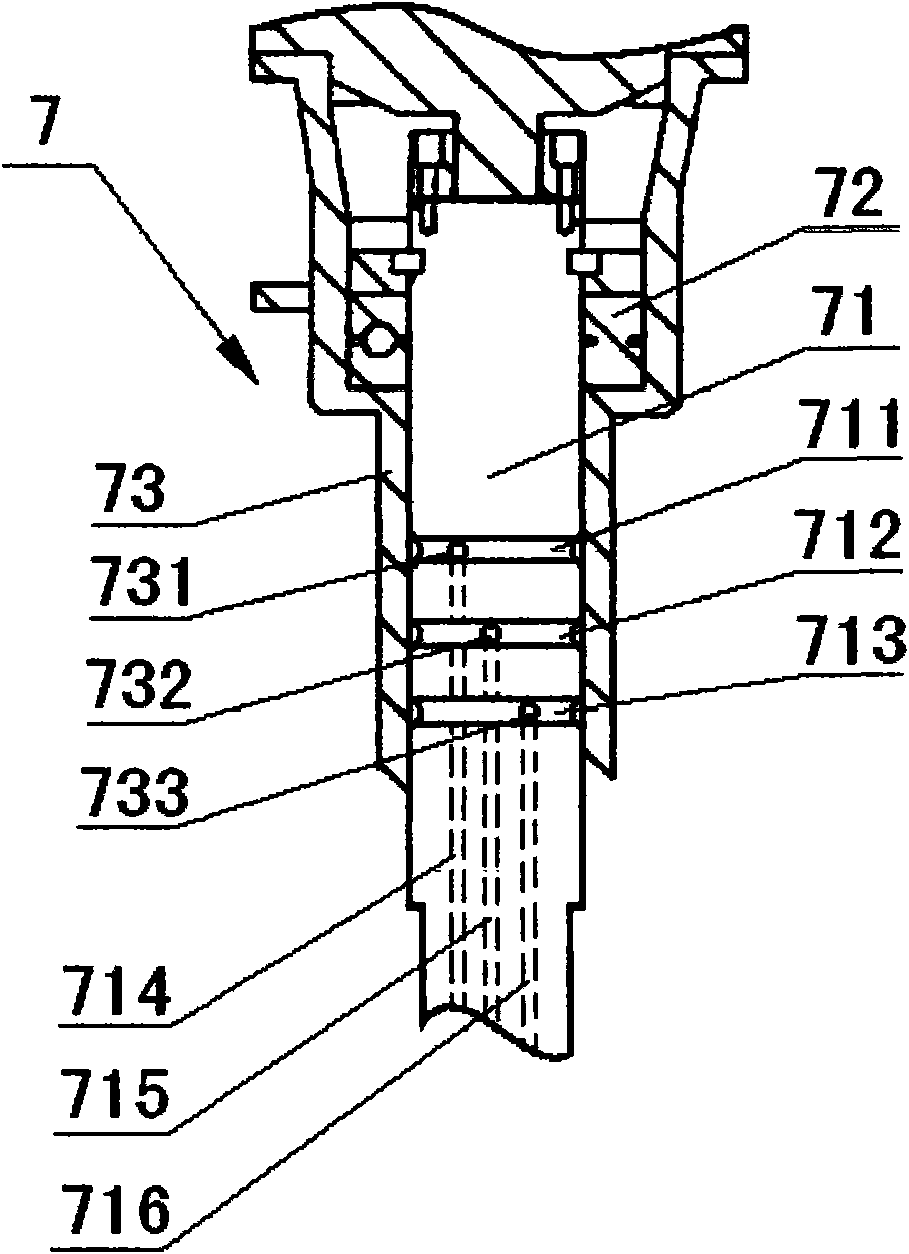

[0011] The rotary device 7 is composed of a rotary connecting shaft 71, a bearing 72, and a shaft sleeve 73. A bearing 72 is arranged between the upper end of the rotary connecting shaft 71 and the shaft sleeve 73; The upper end of the rotary connection shaft 71 of 7 is fixedly connected, and the lower end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com