Backlight module and liquid crystal display

A liquid crystal display and backlight module technology, applied in the directions of instruments, optics, light guides, etc., can solve the problems of increased production costs, easy lifting or separation, and measurement of ripples on the light guide plate, so as to improve uneven projection or light leakage and save energy. Material cost, compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

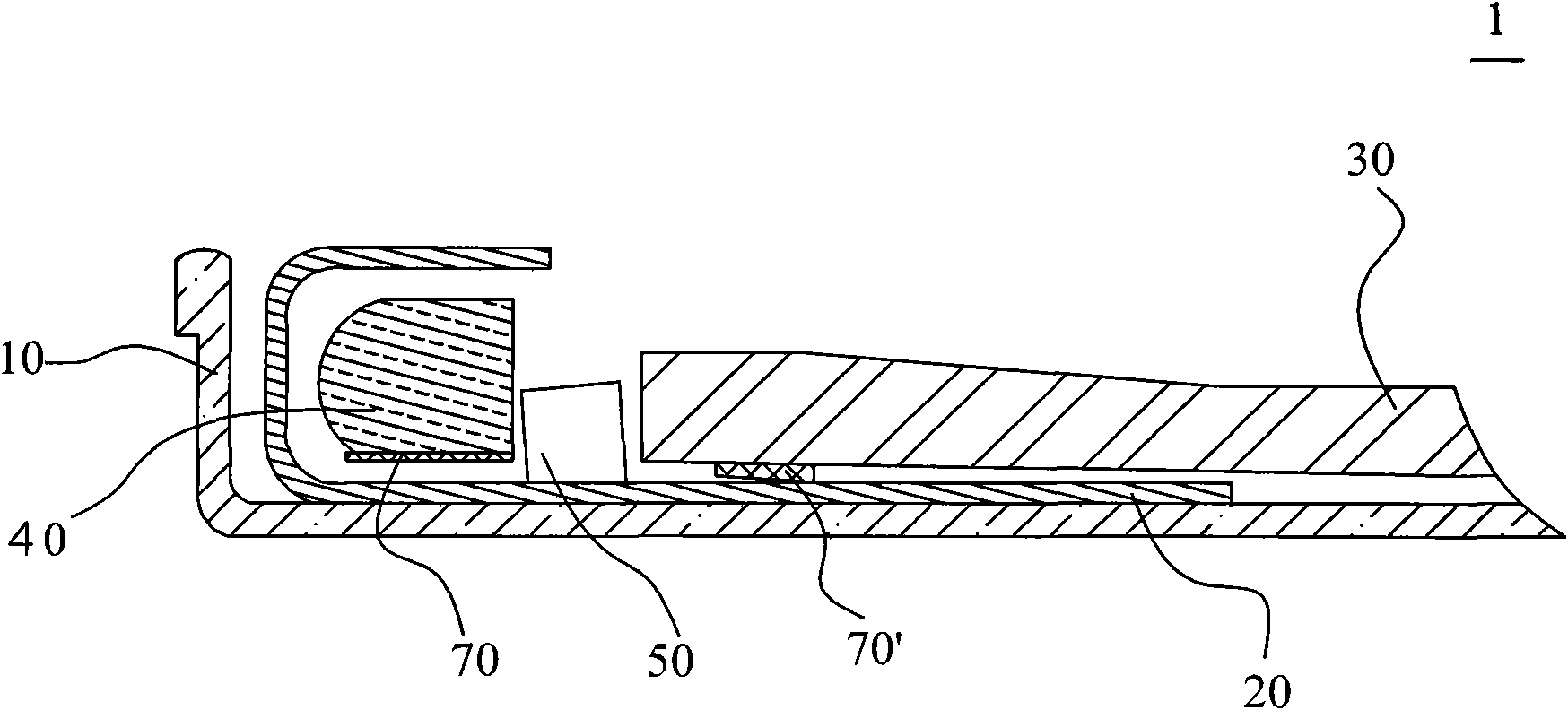

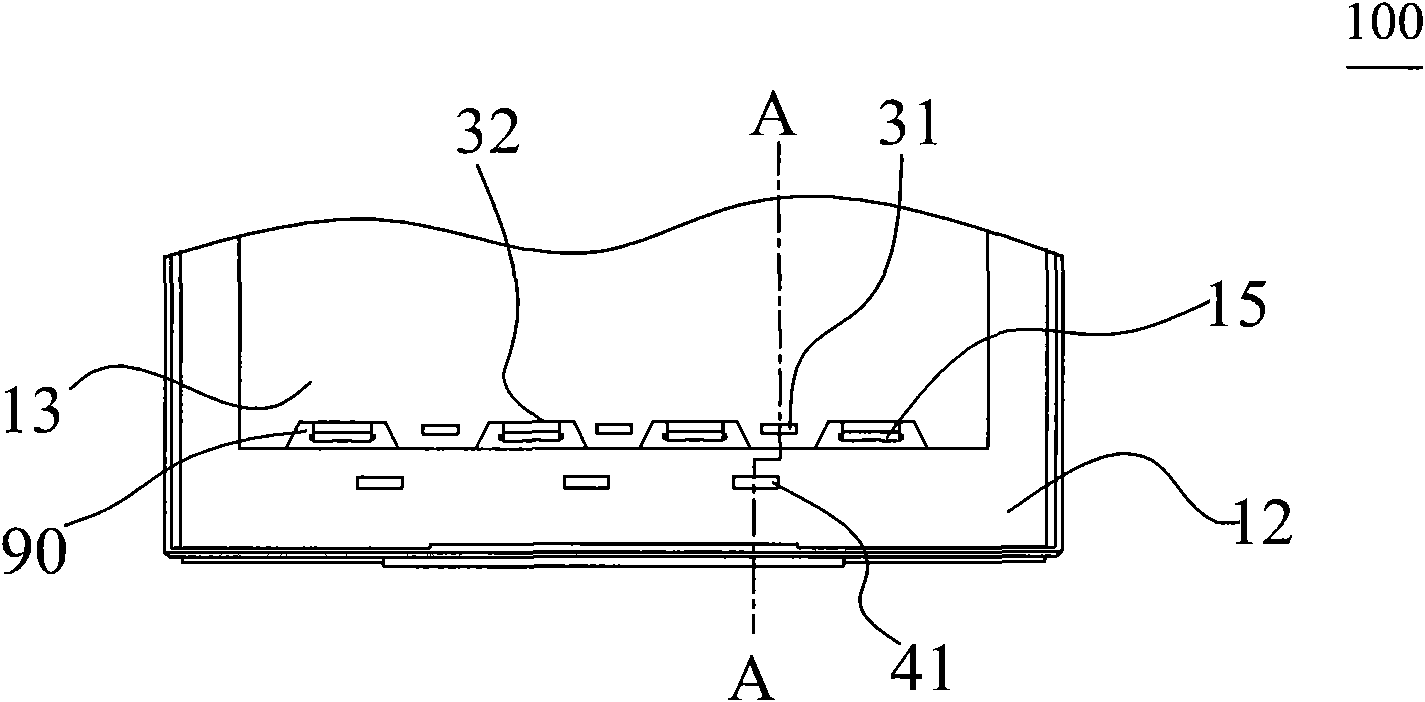

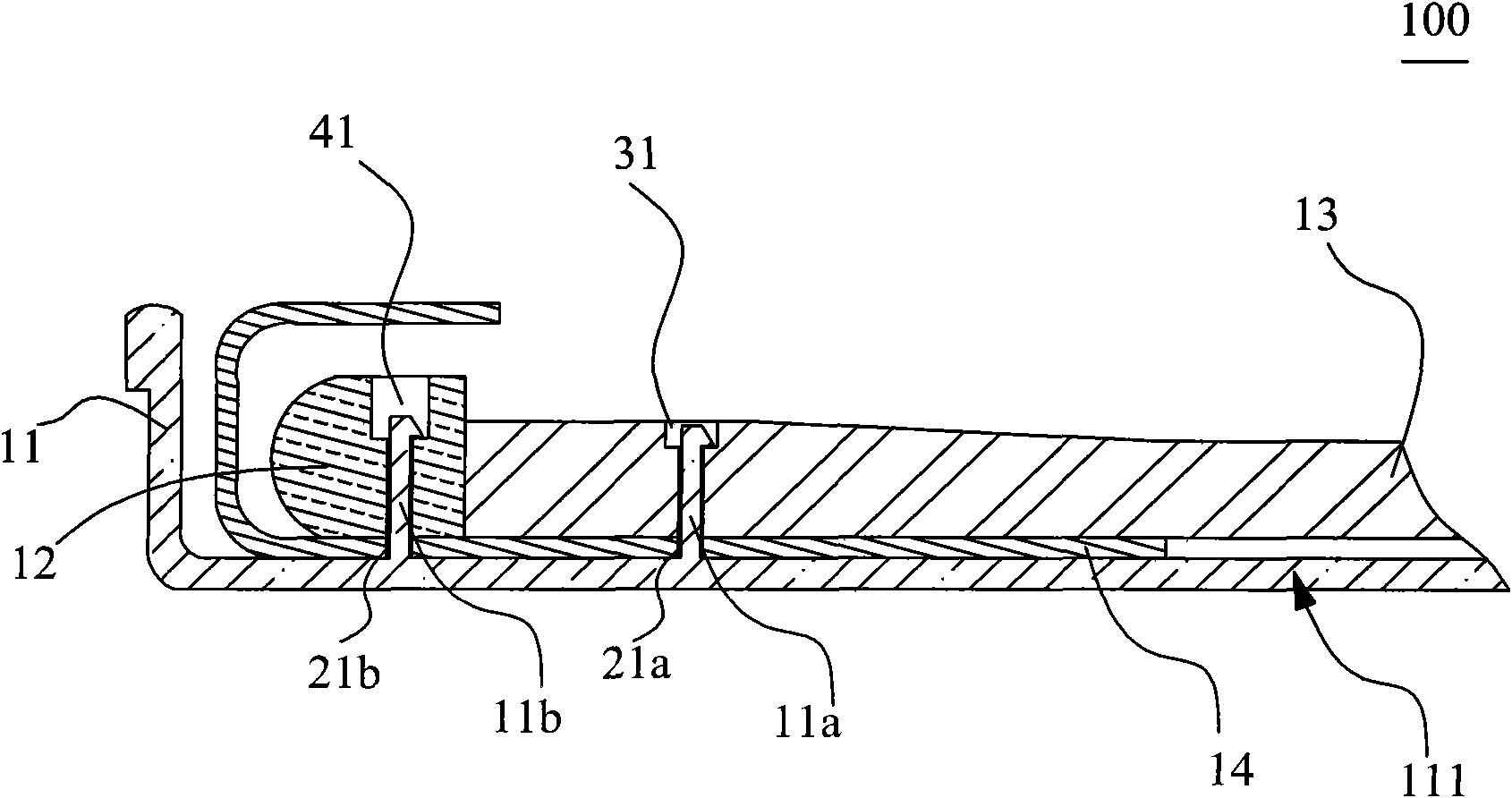

[0021] See figure 2 with image 3 , figure 2 It is a schematic top view of the first preferred embodiment of the backlight module of the present invention, image 3 for figure 2 A schematic cross-sectional view of line A-A. The present invention provides a backlight module 100 , which includes a backplane 11 , a frame 12 , a light guide plate 13 and a light source module. The light source module includes a circuit board 14 and a plurality of light emitting diodes 15 . The light guide plate 13 has a light incident surface 32, wherein in this embodiment, one side of the light incident surface 32 of the light guide plate 13 has a plurality of grooves 90, the grooves 90 are used to accommodate the light emitting diodes 15, of course, the other In an embodiment, the groove 90 may also be located on a side of the frame body 12 facing the light-incident surface 32 . In addition, the light guide plate 13 has at least one first through hole 31 . The frame 12 is disposed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com